20T biaxial friction welding machine for automobile tubular beam friction welding machine

-

Supplier: Zhonghe Machinery Technology(Dalian) Co., Ltd. -

Region: Liaoning, China -

Contact: Ms Anna Yang -

Price: $115000.00 /set -

Min. Order: 1 set

Product details

| Mechanical test report: | if | Core components: | PLC, engine, bearing, motor, pressure vessel, gear |

| Main selling points: | Low maintenance cost, high productivity | aspect: | custom made |

| Health status: | new | Applicable industries: | Energy & Mining, Automotive, Agriculture & Trucks, Bimetals & Specialty, Military, Oilfield Parts |

| Weld diameter: | 3-150 mm | Rated Capacity: | 100% |

| Marketing Type: | normal product | brand: | Joined forces |

| type: | friction welding machine | Origin: | Liaoning, China |

| aspect: | Different models and different sizes | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Packaging Details: | Export standard packaging, wooden box packaging film. Can also be requested by customers. | Core component warranty: | 1 year |

| Voltage: | 380V | Rotating speed: | rely on |

| Video shipment inspection: | if | Rotary fixture clamping length: | 20-300mm |

| Maximum Thickening Force: | 25-1200 kN | Movement fixture clamping length: | 80-450mm or unlimited |

| Showroom location: | not any | usage: | metal welding, friction welding machine |

| Warranty: | 1 year | port: | Dalian |

| Weight (kg): | 250000 kg | After warranty service: | Video technical support, online support, |

Product overview

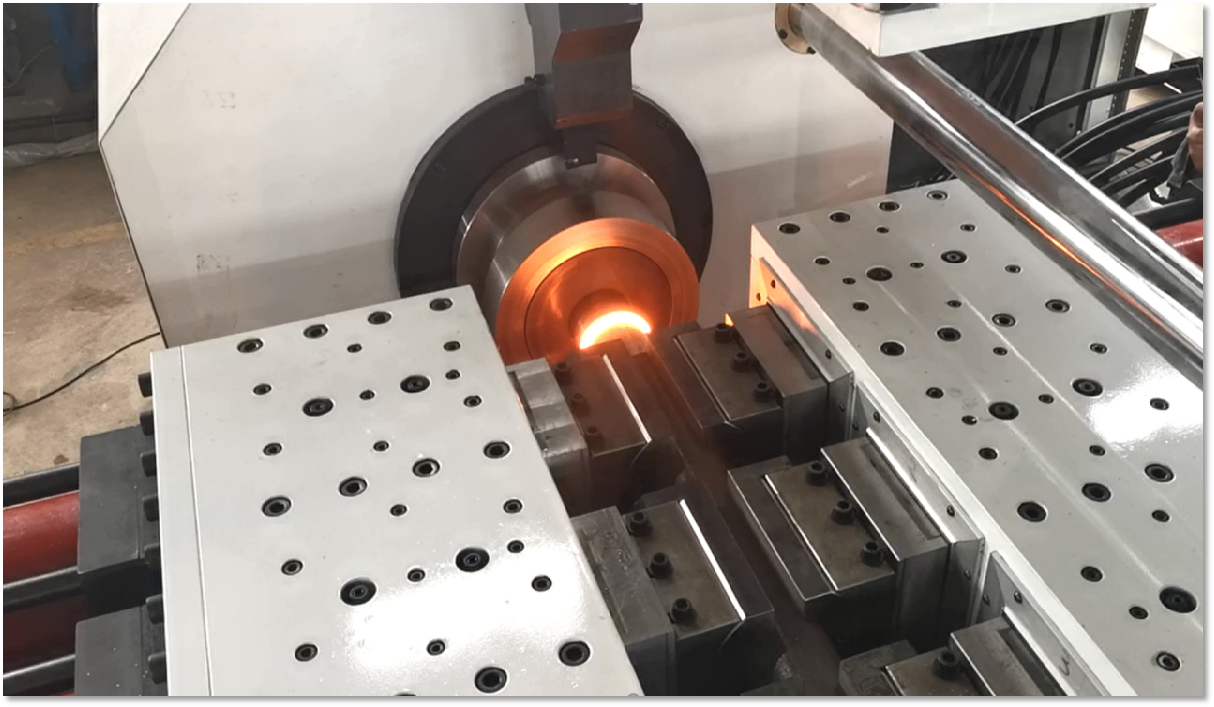

What is Friction Welding?

Friction welding is a solid-state joining technique that uses mechanical friction to generate heat to weld workpieces. Utilizes heat generated between surfaces by a combination of mechanically induced frictional motion and applied loads. by "joining forces"

Friction welding machines, the resulting joints are of forged quality. Under normal conditions, the mating surfaces will not melt.The process does not require filler metal, flux and shielding gas.

advantage

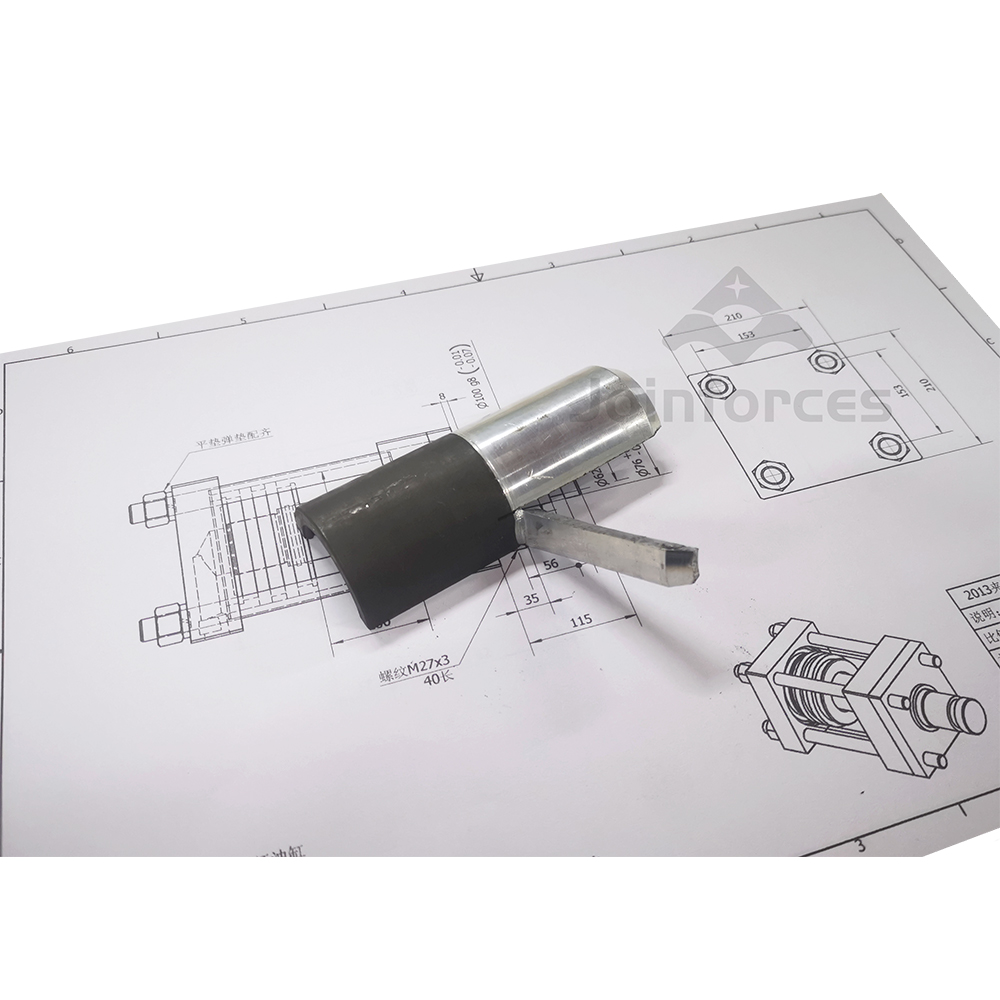

1. Easily join dissimilar metals. This means being able to use more expensive corrosion resistant materials where required, and

Where not required, use less strong but adequately strong materials on the same part.

Where not required, use less strong but adequately strong materials on the same part.

2. The welding process consumes its own base metal to achieve metallurgical bonding, resulting in friction welding joints and

Forging quality and strength.

Forging quality and strength.

3. The entire surface of the cross section is composed of two metals, which is airtight and has no voids. Friction welding is usually less expensive because

There are no consumables such as filler metal flux.

There are no consumables such as filler metal flux.

product specification

Model | maximum. Upsetting force (KN) | Moving Fixture Workpiece Length(mm) | Welding diameter (mm) | RPM(MAX.) Variable(r/min) |

ZHFW-2 | 20 | 20-140 | 5-13 | 5000 |

ZHFW-5 | 50 | 50-260 | 8-18 | 3000 |

ZHFW-12 | 120 | 150-700 | 14-30 | 1500 |

ZHFW-20 | 200 | 150-1020 | 14-36 | 1500 |

ZHFW-30 | 300 | 314-1600 | 20-45 years old | 1200 |

ZHFW-40 | 400 | 500-2400 | 25-55 years old | 1100 |

ZHFW-63 | 630 | 960-3400 | 35-64 years old | 1000 |

ZHFW-80 | 800 | 1300-5000 | 40-75 | 950 |

ZHFW-100 | 1000 | 1600-6000 | 45-86 | 890 |

ZHFW-125 | 1250 | 2000-7800 | 50-100 | 600 |

ZHFW-160 | 1600 | 4300-8792 | 89-160 | 580 |

ZHFW-200 | 2000 | 5100-12500 | 102-189 | 500 |

ZHFW-250 | 2500 | 3850-15500 | 70-140 | 500 |

ZHFW-320 | 3200 | 6400-20000 | 90-160 | 380 |

ZHFW-400 | 4000 | 8000-25000 | 100-180 | 350 |

ZHFW-500 | 5000 | 8000-31400 | 100-200 | 320 |

ZHFW-700 | 7000 | 8000-44000 | 100-240 | 320 |

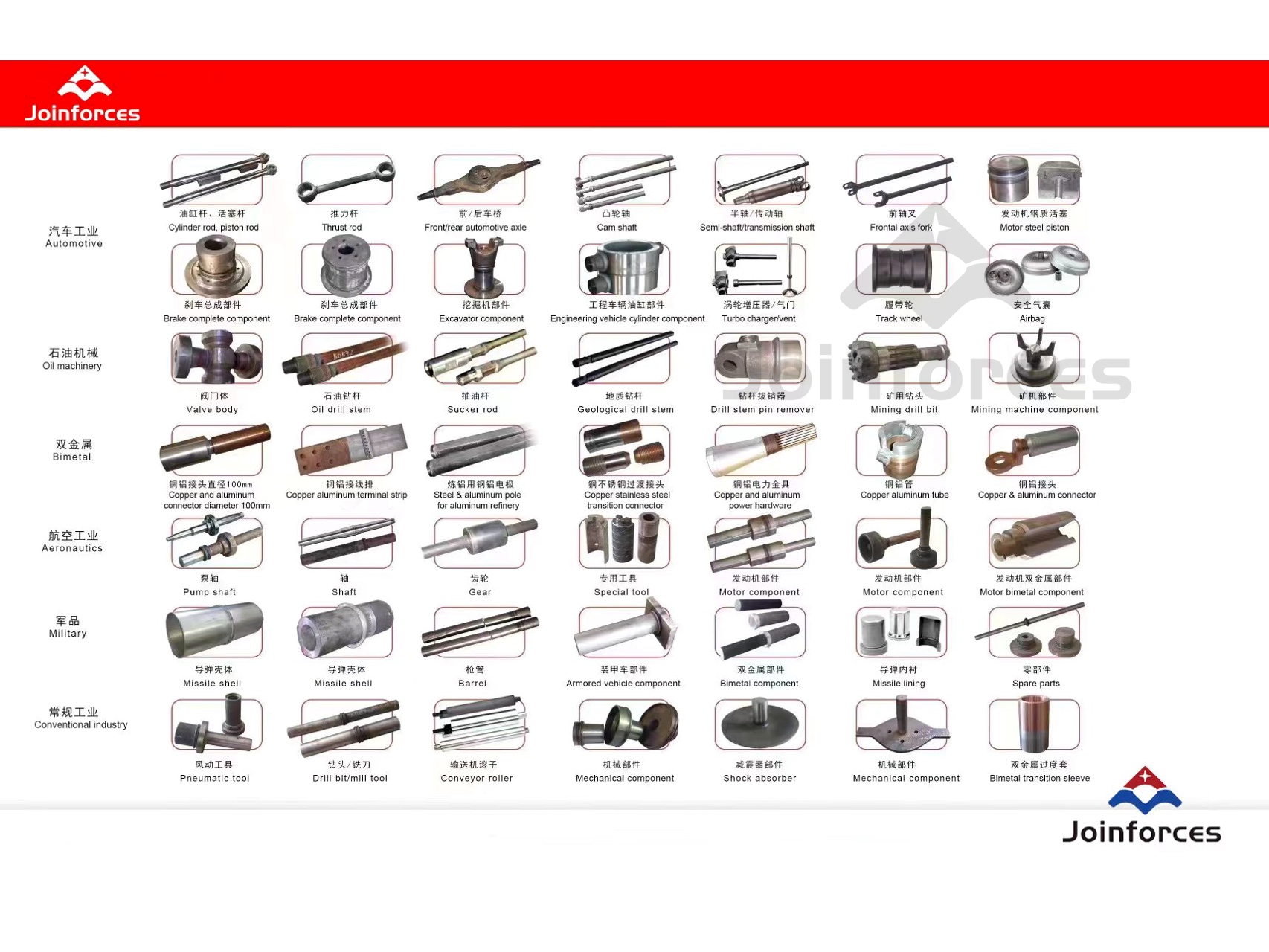

application

VIEW MORE

You may like

-

Cable friction welding machine

-

Direct drive friction welding machine high precision friction welding machine

-

Mining drill pipe friction welding machine Rotary friction welding machine

-

80 tons drill pipe friction welding horizontal friction welding machine

-

Cable friction welding machine

-

Automatic friction welding/stir welding machine

-

Jinan CNC Steel Pipe Friction Friction Welding Machine For Sale

-

Low cost CNC friction welding for drill pipe

-

Direct friction welding machine

-

Horizontal aluminum copper cable terminal friction welding machine

Other Products

-

$85000.00 / set

$85000.00 / set -

$106000.00 - $108000.00 / set

$106000.00 - $108000.00 / set

Related Search

car wash machin for automobil suppliers

brake for automobil suppliers

hydraulic jack for automobiles suppliers

emission tester for automobile

electrical parts for automobiles

welding machine for pe pipe

spot welding machine for sheet

ultrasonic welding machine for non woven bag

gas weld machin for sale suppliers

machines for gas welding suppliers