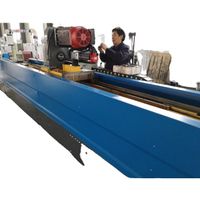

cnc skiving and roller burnishing machine manufacturer

-

Supplier: Yantai Haige Machine Tools Co., Ltd. -

Region: Shandong, China -

Contact: Mr Jingping Ren -

Price: $200000.00 /set -

Min. Order: 1 set

| Weight: | 15t; | Packaging Detail: | plywood box + plywood pallet + plastic foam; |

| Certification: | ISO9001; | Port: | Qingdao; |

| Payment Terms: | T/T,Western Union,MoneyGram; | Delivery Detail: | 3-4month; |

| Dimension(L*W*H): | 25400*3600*2200(mm); | Brand Name: | Haige; |

| CNC or Not: | CNC; | Supply Ability: | 50 Piece/Pieces per Year; |

| Warranty: | 1 year; | Power(W): | 100KW; |

| color: | customized; | Voltage: | 220V; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Model Number: | ZTG2590; |

| Condition: | New; | Place of Origin: | Shandong China (Mainland); |

Professional hydraulic cylinder boring and honing machine manufacturer in China We can provide CNC Skiving & Roller Burnishing Machines with different configurations that can process work pieces with inner diameters from Ø40 to Ø250 and the lengths of 1.5m, 2m, 3m, 4m, 6m, 9m, and 10m, among others.

Field of Application:

Contruction machinery, colliery hydraulic holder, colliery scaper conveyor, special usage truck, maritime ship, harbour machinery, petroleum machinery, mining machinery, water conservancy machinery etc.

Model ZTG2530 ZTG2560 ZTG2590

Workpiece

dimension

Internal diameter(mm) Φ50-250 Φ80-250 Φ90-250

External diameter(mm) Φ60-300 Φ90-300 Φ100-300

Processing length(mm) 500-3000 1200-3000 1650-9000

Spindle speed(r/min) 50-1500 50-1500 50-1500

Locating seat movement

(mm/min) 6000 6000 6000

Spindle box movement

(mm/min) 8000 8000 8000

Motor power Spindle servo

(Kw) 37/56 37/56 37/56

Feed servo(Kw) 6 6 6

Total motor power 90 90 100

Main Features

Advantages compared with traditional honing

1) Improve processing efficiency: Processing speed is nearly 20 times that of honing.

2) Enhance surface hardness: Surface hardness is increased by more than 50%.

3) Processing precision: Processing precision can reach level IT8, and surface roughness can reach Ra0.05-0.4μm.

4) Working environment: Low noise, non-pollution, labor cost-saving.

5) Reasonable processing arrangement: Skiving & roller burnishing can be arranged as the last operation after the others (such as drilling oil filler hole, welding, threading).

Machine Parts

Name: Bliwing Cylinder

Clamping base: clamp male cone of the work piece by moving the hydraulic cylinder against the locating base, to have the work piece fixed.

Headstock

Ensure large torque at low speed and constant power output at high speed by adopting ZF gear two-speed transmission box made in Germany. Imported precision bearing is adopted for the main shaft, to ensure its stiffness and precision.

Locating base:

a new locating base locking device is adopted to fix the locating base at the desired place.

Work piece supports:

there are two work piece supports. With a V structure, each of them can be adjusted freely according to outer diameter center of the work piece. For they are installed on the guide rail slide, it is convenient and easy to push them.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

bright bar peeling machine

91.8% Response Rate

bar straightening machine

91.8% Response Rate

bright bar production line

91.8% Response Rate

-

VHM170 Siemens automatic cylinder honing machine, used for honing single-line engine cylinders

-

Portable boring and honing machine sbm100 for maintenance

-

SBM100 Motorcycle Engine Cylinder Boring Machine

-

Motorcycle Boring Honing Machine TM807A Portable Cylinder Boring Honing Machine

-

China perfect low price intelligent control 2MK2150X4 deep hole honing machine cylinder honing machine

-

Honing Head MT82 (used for 2M2217A)

-

3MB9817 Vertical cylinder honing machine from China factory

-

3M9735BX150 Cylinder block and head honing machine with CE

-

TM807A Portable Motorcycle Cylinder Boring and Honing Machine

-

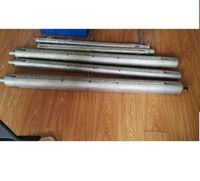

Honing bar

Other Products

-

$100000.00 / set

$100000.00 / set -

$100000.00 / set

$100000.00 / set -

$25000.00 / set

$25000.00 / set