Double Sided Spot Battery Welding Machine Automatic For Cylindrical Lithium Battery

-

Supplier: Shenzhen Hualianneng Technology Development Co., Ltd -

Region: Guangdong, China -

Contact: Mr Martin Brady -

Price: $17000.00 / 1 - 10 pieces

$16000.00 / 11 - 20 pieces -

Min. Order: 1 piece

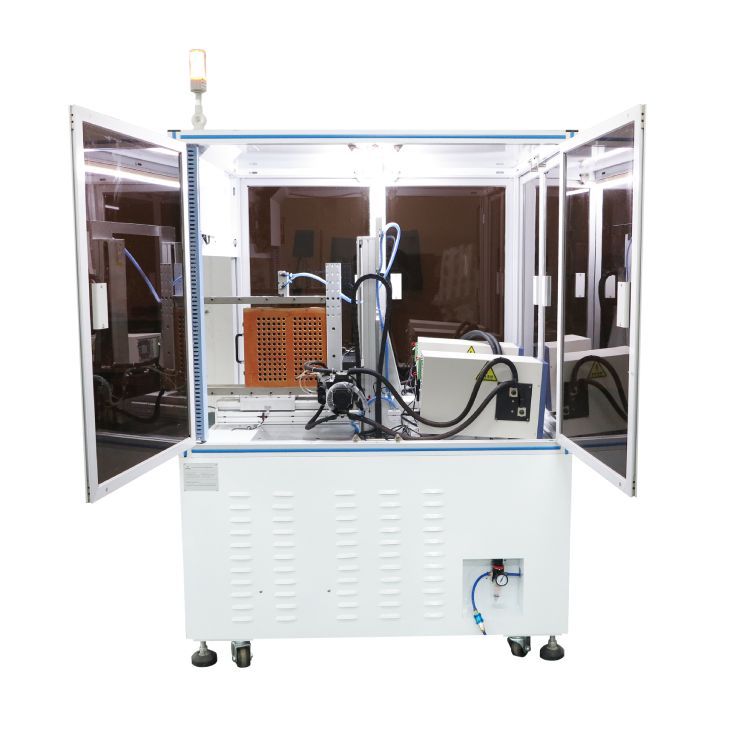

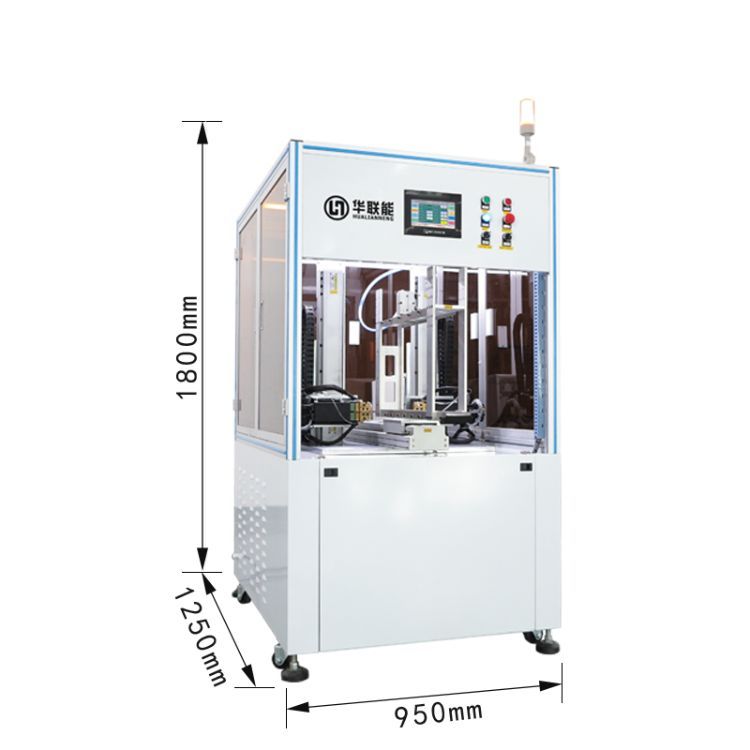

Hualianneng-DH-SM01 is mainly used for welding the battery and the nickel strip in the cylindrical battery PACK, and the welding tension between the battery and the nickel is ≥30N, suitable for spot welding lithium battery of the electric motorcycle,electric car, solar street lighting and electric tools.

This equipment adopts high precision closed-loop motor, high precision guide rail, equipped with DC inverter welding power source, welding head with photoelectric system to real-time check nickel strip position, adjustable welding pressure, which ensure the battery welding strength, tidy uniform welds.

Movement control CARDS embedded system + human-machine interface, easy operation, multi-function system with variety of programming model, can store Max 999 groups for editing different battery PACK data. Fast switching,high automation, good stability.

| |||||||||||||||||||||||||||||||

Product Specification1. The welding voltage locking technology prevents the network voltage fluctuation from affecting the welding current;

2. Adjustable welding pulse width, small welding spatter, welds color no changing.

3. Two sections current monitoring and comparing function, abnormal current sound and light alarm, effectively preventing the rosin joint.

4. Fault self-diagnosis function, display the corresponding fault points,convenient maintenance.

5. Motion control card embedded programming module, automatically generate the welding pole movement track and save it in the system file through inputing the space and group number after confirming the relevant position. Super simple and easy to learn programming

6. 999 groups welding program and parameters data storage capacity in the system, switching program per different products.

7. Display screen: Touchable microcomputer, easy operation, multi-function, real-time monitoring the operation status & target capacity.

8. The welding pole equipped with photoelectric induction to ensure that the nickel strip located in position before spot welding, eliminating the false welding from the root.  | |||||||||||||||||||||||||||||||

-

SW-2500 Capacitor Discharge Stud Welder Inverter Carbon Steel Stud Welder

-

China factory production hot sale wholesale hardware wire mesh factory dedicated 300KVA gantry multi-row welding machine multi-point welding machine

-

Automatic Resistance Roll Seam Welders for Chimney Welding, Stainless Steel and Carbon Chimney Welders

-

Stud Welder Capacitor Discharge Welder Carbon Steel Inverter Welder

-

Battery Welding Machine Resistant Welder 18650 21700 26650 32700 Battery Pack Welder

-

Ordinary self-fur welded mesh machine

-

AC high-efficiency intermediate frequency inverter DC spot welding machine/pedal resistance spot welding machine

-

Steel bar welding machine net width 2500mm diameter 6mm to 12mm

-

WIP-70A-05YC/WIT-70A(YPB-200) Customized Inverter DC Resistance Welding Power Source Portable Spot Welding Machine

-

Carbon Steel Spot Welding Machine Customized Spot Welder Resistance Welder Manufacturer

Other Products

-

$6000.00 / piece

$6000.00 / piece -

$750.00 - $1250.00 / piece

$750.00 - $1250.00 / piece -

$1200.00 - $1250.00 / piece

$1200.00 - $1250.00 / piece