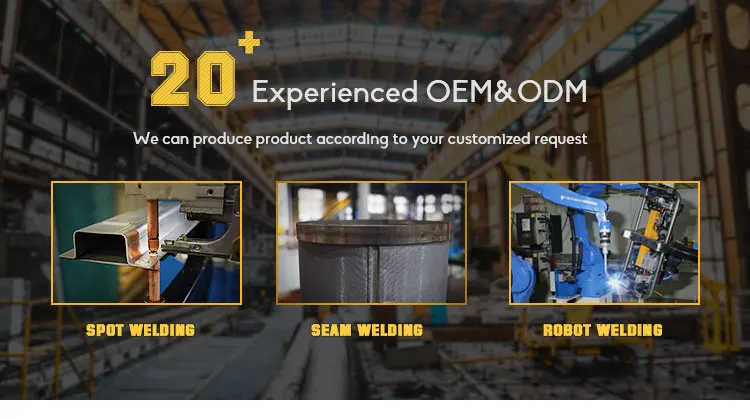

Carbon Steel Spot Welding Machine Customized Spot Welder Resistance Welder Manufacturer

-

Supplier: Shanghai Trintfar Intelligent Equipment Co., Ltd. -

Region: Shanghai, China -

Contact: Mr Trintfar trintfar -

Price: $12000.00 / 1 - 99 sets

$2000.00 / >=100 sets -

Min. Order: 1 set

Product details

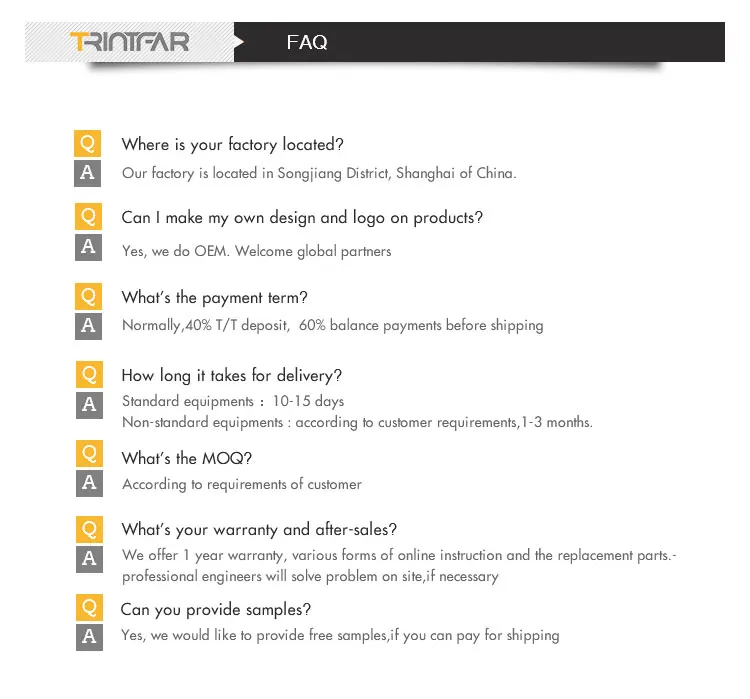

| Packaging Detail: | wooden box; | Warranty of core components: | 3 years; |

| After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; | Condition: | New; |

| Showroom Location: | None; | Usage: | Welding; |

| Key Selling Points: | Competitive Price; | After Warranty Service: | Video technical support,Spare parts,Field maintenance and repair service; |

| Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Machinery Repair Shops,Manufacturing Plant,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Other,Advertising Company; | Cooling Water: | 20-60L/min; |

| Core Components: | PLC,Pressure vessel; | Electrode Pressure: | 1200N-18000N; |

| Electrode Stroke: | 50-100mm; | Port: | Shanghai; |

| Rated Duty Cycle: | 50%; | Marketing Type: | Ordinary Product; |

| Supply Ability: | 500 Set/Sets per Month; | Maximum short current: | 10KA-120KA; |

| Rated duty cycle: | 50%; | Weight (KG): | 400; |

| Local Service Location: | None; | Power (kW): | /; |

| Brand Name: | TRINTFAR; | Warranty: | 3 years; |

| Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram; | Product Name: | High quality resistance spot welding machine; |

| Dimensions: | /; | Place of Origin: | Shanghai China; |

| Rated Capacity: | /; | Machinery Test Report: | Provided; |

| Video outgoing-inspection: | Provided; |

MD Frequency Inverter Resistance Spot Welding Machine

Feature

- The power supply unit's duty are balanced. Three phase power make MD frequency inverter more adaptable in winding and pressure of wire.

- More preaser, faster current control, can analyse parameters more and faster compare with power frequency system.

- Faster to set up current, the speed is 20folds quicker than traditional technic

- Process more reliable: the majority of the application of solder DC welding metal effect will be even better.

- Reduce operating costs, including energy savings each and every point of welding as well as shortening the welding cycle.

- Save energy :especially suitable for welding thick workpieces and high-conductivity metal .such as aluminum and galvanized steel sheet.etc.

|

Item |

|

|

|

|

|

|

|

|

MD-10T |

10 |

50 |

≈9.8 |

≤20 |

1200 |

50 |

20 |

|

MD-20 |

20 |

50 |

≈9.8 |

≤50 |

4700 |

80 |

24 |

|

MD-25 |

25 |

50 |

≈9.8 |

≤70 |

4700 |

80 |

24 |

|

MD-40 |

40 |

50 |

≈11.6 |

≤120 |

7300 |

80 |

30 |

|

MD-60 |

60 |

50 |

≈11.6 |

≤160 |

12000/18000 |

100 |

50 |

|

MD-80 |

80 |

50 |

≈11.6 |

≤240 |

12000/18000 |

100 |

50 |

|

MD-120 |

120 |

50 |

≈11.6 |

≤300 |

18000 |

100 |

60 |

Appication

Suitable for welding thick workpieces and high-conductivity metal .such as aluminum and galvanized steel sheet.etc.

VIEW MORE

You may like

-

SW-2500 Capacitor Discharge Stud Welder Inverter Carbon Steel Stud Welder

-

China factory production hot sale wholesale hardware wire mesh factory dedicated 300KVA gantry multi-row welding machine multi-point welding machine

-

Automatic Resistance Roll Seam Welders for Chimney Welding, Stainless Steel and Carbon Chimney Welders

-

Stud Welder Capacitor Discharge Welder Carbon Steel Inverter Welder

-

Double Sided Spot Battery Welding Machine Automatic For Cylindrical Lithium Battery

-

Battery Welding Machine Resistant Welder 18650 21700 26650 32700 Battery Pack Welder

-

Ordinary self-fur welded mesh machine

-

AC high-efficiency intermediate frequency inverter DC spot welding machine/pedal resistance spot welding machine

-

Steel bar welding machine net width 2500mm diameter 6mm to 12mm

-

WIP-70A-05YC/WIT-70A(YPB-200) Customized Inverter DC Resistance Welding Power Source Portable Spot Welding Machine

Other Products

-

$1500.00 - $4400.00 / set

$1500.00 - $4400.00 / set -

$4500.00 / set

$4500.00 / set -

$5000.00 / set

$5000.00 / set

Related Search

carbon steel butt welded fittings

inverter welding machine air plasma welder cut 40

carbon steel pipe bending machine coil

spot welders manufacturers

6mm carbon steel plate bending machine

automatic steel pipe welding machine

steel mesh welding machin

dn 35 stainless steel spot welding machine

spot welding machine

mobil spot weld machin suppliers