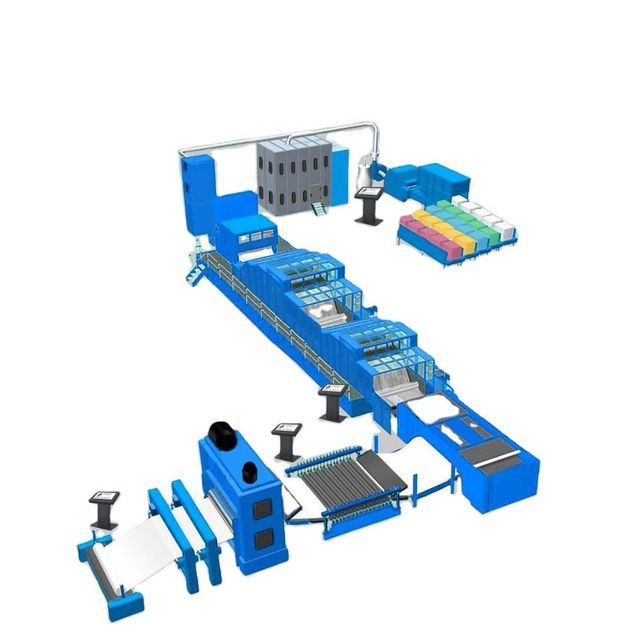

Tongda TDL-GI Textile Machinery Non-woven Non-glue Cotton Production Line Felt Polyester Fiber Non-woven Equipment

-

Supplier: Qingdao Tongda Textile Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Mr jerry zhao -

Price: $200000.00 /set -

Min. Order: 1 set

Product details

| Supply capacity: | 10 sets per month | Product net width: | 1000mm-2500mm |

| Applicable industries: | manufacturing plant | Grinding speed: | 35m/min |

| product weight: | 100-2500 g/m2 | Video shipment inspection: | if |

| Mechanical test report: | if | Marketing Type: | New product |

| Voltage: | 380V 50HZ | port: | China |

| Health status: | new | Installed power: | 7-11kw |

| payment terms: | L/C, Western Union, T/T | brand: | Mastery |

| Production capacity: | 99% | product name: | Non-woven production line |

| Core component warranty: | 1 year | Warranty: | 1 year |

| Packaging Details: | Bare package or according to customer requirements | capacity: | 300kg/day-5 tons/day |

| Package preview: | Automatic level: | automatic | |

| Needle Density: | 4000-8000n/m | Needle travel: | 25-50mm |

| weight: | 100000 kg | Main selling points: | automatic |

| strength: | 24 watts | Core components: | Engines, Bearings, Gears |

| output width: | 2500-10000mm | Origin: | Shandong China |

| After-sales service provided: | Engineers available to service machinery overseas |

Textile non-woven cotton batting production line non-woven machine

Tongda non-woven production equipment production line can produce different types of various fashion patterns. Thermally bonded cotton non-woven fabric/Geotextile non-woven fabric/Automotive interior automotive fabric/Waterproof material/Cotton-free cotton thread/Filter felt/Wool felt non-woven fabric/Synthetic leather non-woven fabric. These machines are produced after years of research and experimentation by our entire technical staff. It is a new type with high performance, simple operation and strong performance. Sewing industries such as clothing, industry, interior decoration, etc., users love to use these new machines.

Functions and Features

♥ This machine is used to process the fiber web to obtain the required hard and thick thermal bonded cotton.

♥Low melting point fibers will be reinforced by bonding other fibers together through the hot air penetration and cooling system.

♥Making heat bonded cotton for clothing, mattresses, chemically bonded cotton, 3M-Thinsulate

Filling for linings, quilts, home textiles, etc.

structure

♥ One-way double-belt structure

♥ The top and button straps secure the fiber cotton pad at the oven entrance, allowing it to be heated as it forms its structure.

♥ The belt gap can be adjusted within the range of 50~250mm

♥ The belt is made of Teflon coated manganese base material

♥ Unique special air duct design, allowing hot air to permeate from top or bottom

The main specifications of this non-woven machine

fiber type | natural fiber or synthetic fiber etc. |

working width | ≤9000mm |

capacity | 300kg/day-5 tons/day |

product weight | 100~9000g/square meter |

Product thickness | 3~200mm |

Installed power | 7-11kw |

output width | 2500-10000mm |

grinding speed | 35m/min |

Needle stroke | 25-50mm |

needle density | 4000-8000n/m |

needle frequency | 800-1200 rpm |

needle type | Single board/double board, up/down travel |

work pressure | 100kg/cm |

mechanical speed | 4000mm/min |

surface temperature | 260 degrees Celsius |

structural style | 2/3 volume |

heating method | hot oil circulation |

surface temperature | ≤220℃ |

heating method | Thermal oil circulation, electric heating, direct combustion |

ovens work together | 4.8m-9.0m |

Heating oven / non-woven machine picture

Non-adhesive batting production line/wool felt non-woven production line uses low-melting point or bi-component fibers mixed with ordinary fibers to make rigid batting, or foam substitutes for cushions, mattresses, soundproof and insulating felts, etc., are also available Soft wadding for making interlinings for home textiles, clothing, furniture, toys, etc.

The material after forming the batting passes through a stainless steel or belt oven according to the product. Where the top waist belt is mounted is a removable compression waist belt. However, for soft fillings, such as bulky materials below 1500 grams per square meter, it is normal to use belts in the oven. The production line can produce various needle-punched geotextiles or other needle-punched products. The line can add batting and 1 or felt drafter. Needle looms with different needle types and 1 or density are available depending on the end use of the product.

Product packaging

exhibition

Our advantage

VIEW MORE

You may like

-

Disposable Massage Bed Cover Bed Sheet Making Machine Cover Making Machine Non Woven Fabric Perforating Machine

-

Germany Free Sample Nonwoven Fabric Making Machine Nonwoven Fabric Making Machine Nonwoven Fabric Machine

-

Disposable Medical Garment Non-Woven Making Machine For A Long Sleeve Doctor's Apron

-

Felt Mattress Production Line High Quality Waste Recycling Machine

-

Hot-bonded polyester fiber quilt/quilt making machine/hot-bonded cotton production line

-

Polyester staple fiber making machine

-

Polyester fiber opening machine Wool fiber carding machine

-

Electric 3D-15D Polyester Cotton Opener Pillow Sofa Pillow Cushion Filling Machine Textile Fiber Opener

-

Polyester Opening Carding Pillow Filling Machine Waste Cotton Fiber Opening Machine Seat Cushion Plush Filling Recycling Machine

-

Fully automatic computerized embroidery single head carpet tufting machine

Other Products

-

$43000.00 / set

$43000.00 / set -

$45000.00 / set

$45000.00 / set -

$60000.00 / set

$60000.00 / set -

$10000.00 / set

$10000.00 / set -

$45500.00 / set

$45500.00 / set -

$4000.00 / set

$4000.00 / set -

$63504.00 / set

$63504.00 / set -

$120000.00 / set

$120000.00 / set -

$100000.00 / set

$100000.00 / set

Related Search

textile machinery

apparel textile machinery

creel textile machinery

dyeing machinery textile machinery

textile machinery weaving loom

textile machinery clutch

non ferrous equip suppliers

polyester fiber opening machine in home textile

production lines and machinery food

salt production line in machinery