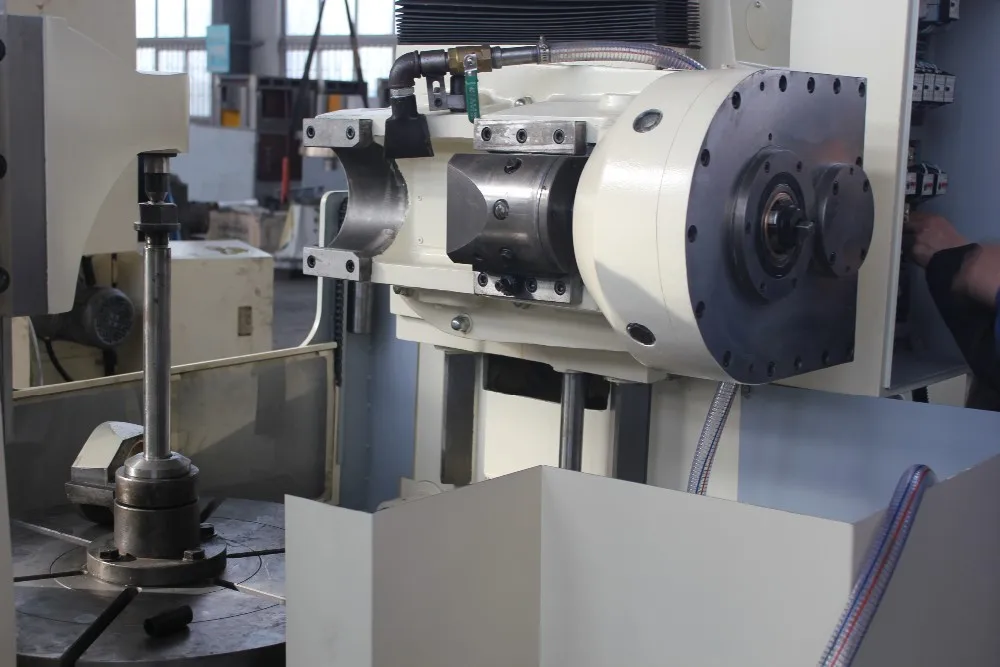

YK3180 Vertical CNC Gear Hobbing Machine for Sale

-

Supplier: Dalian Dahui Machine Tool Co., Ltd. -

Region: Liaoning, China -

Contact: Mr Hui Liu -

Price: $60000.00 /set -

Min. Order: 1 set

| Warranty: | 1 Year; | Packaging Detail: | Plastic cloth for the first layer, canvas for the second layer, and packing with wooden case at last, together with pallet on the bottom of wooden box for High Quality Advanced Gear Cutting Machine YK3180; |

| Brand Name: | DMTC; | Payment Terms: | L/C,T/T,Western Union; |

| main motor power: | 7.5kw; | Power(W): | 5.5kw; |

| max module: | 10mm; | Voltage: | 220/380/440; |

| Type: | Gear Hobbing Machine; | max size of bob(D*L): | 160*160mm; |

| Port: | DALIAN; | After-sales Service Provided: | Overseas service center available; |

| max speed of worktable: | 36r/min; | Dimension(L*W*H): | 2960*2200*1990; |

| Certification: | ISO9001 CE BV; | CNC or Not: | CNC; |

| Supply Ability: | 40 Set/Sets per Month Gear Hobbing Machine; | Weight: | 6500/7500; |

| bob shifting distance: | 100/120mm; | CNC controller: | Fanuc/Siemens; |

| Condition: | New; | technology: | can discuss; |

| Max. helix angle: | ±45°; | product type: | Gear Hobbing Machine; |

| After-sales Service Provided: | Online support,Video technical support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service; | Place of Origin: | Liaoning China (Mainland); |

Product Application

YK series gear hobbing machine is capable of processing spur Gear, helical gear, spline, drum-shaped gear, small taper gear, worm gear, sprocket etc. Suitable for automobile, motorcycle, reducer, agriculture machinery, Textile machinery, hoisting machinery, sprocket, elevator and mining machinery, industry gear processing.

Main Features

1. CNC axes: X+Y+Z Axes

2. CNC control system; Mitsubishi CNC control system; Optional accessories for Fanuc or Siemens easy operating and reliable running.

3. Machine bed, column with double-wall structure and heavier design as well to ensure high rigidity, stable precision

4. Capable of clockwise or anti-clockwise milling in gear processing

5. Designing automatic lubricating device, save time and more convenient in machine maintaining

6. High accuracy indexing worm wheel pair utilized on worktable, reliable indexing with high indexing precision

7. Constant temperature control in electrical box to ensure reliable operation.

Machine Parts

Name: Worktable

High precision worm worm gear pair, the realization of the workbench no clearance transmission, meet the accuracy requirement of the teeth.

Table adopts integral structure, good rigidity structure. Workbench structure stability, to better absorb, cutting force and transfer it directly to the base of the machine tool. Has a good damping effect of cutting force and strong rigidity.

Main Features

Name: CNC Controller

CNC control system; Mitsubishi CNC control system; Optional accessories for Fanuc or Siemens easy operating and reliable running.

Machine Parts

Name: Arbor

X, Y, Z feed drive adopts Siemens AC servo feed motor driver, ball screw drive, high precision ball screw bearing group.

Main Features

Name: COOLANT CHIP SYSTEM

Cooling machine adopts two sets of large flow, high head cooling pump, can be used independently, also can be used at the same time. Coolant recovery system is stable and reliable. Equipped with coolant, refrigeration equipment to keep machine tool thermal equilibrium. Equipped with oil mist collection device. Equipped with automatic chip removal unit, automatic separation of the chip side by side, including the scrap car.

CUSTOMER VISITING

* SWEDEN CUSTOMER

BUSINESS CARD

C5112 VERTICAL LATHE

91.8% Response Rate

CW6280E HORIZONTAL LATHE

91.8% Response Rate

VDL800 MACHINING CENTER

91.8% Response Rate

-

China Y3180 CNC gear hobbing machine for sale

-

Special-shaped gear hobbing machine CNC gear processing machine tool processing equipment

-

CNC spline shaft milling machine (horizontal gear hobbing machine) schedule

-

Automatic gear hobbing machine 3180 gear hobbing machine phfauter gear hobbing machine

-

YD3132CNC Ten Axis CNC Dry Metal Rotary Cutting Machine High Precision Factory Price Spindle

-

CNC Spindle Milling Machine (Horizontal Gear Cutting Machine)

-

200mm gear shaper YKD5120D

-

YK3132 CNC gear cutting machine for sale

-

Y5150K Gear Shaper Universal Gear Shaper Manual

-

Y3150 gear hobbing machine large module hobbing machine for sale

Other Products

-

$10500.00 - $16500.00 / set

$10500.00 - $16500.00 / set -

$15000.00 - $18000.00 / set

$15000.00 - $18000.00 / set -

$356500.00 - $390000.00 / set

$356500.00 - $390000.00 / set -

$2954.00 / set

$2954.00 / set -

$47385.00 / set

$47385.00 / set