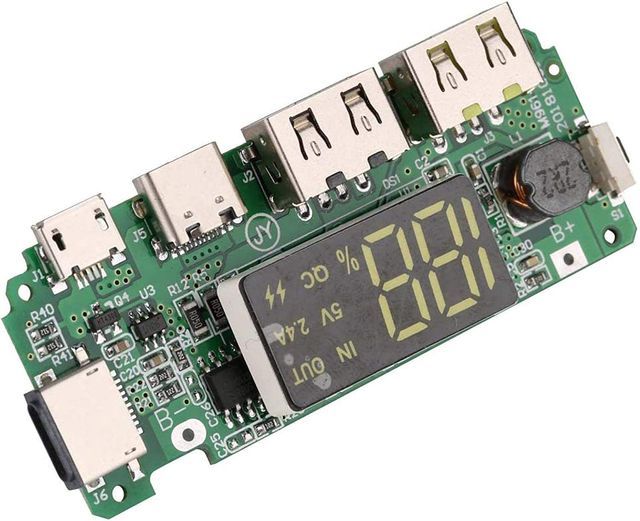

JINHUA PCB FR4 ISO9001 OEM Customized Power Bank Charging Circuit 4.0 Module Design Service USB 5V 2.4A PCBA Prototype PCB Assembly

-

Supplier: Jinhua Technology (Shenzhen) Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Rosia Cao -

Price: $3.50 / 1 - 999 pieces

$1.50 / 1000 - 4999 pieces

$0.50 / 5000 - 9999 pieces

$0.10 / >=10000 pieces -

Min. Order: 1 piece

| port: | Shenzhen | Package preview: | |

| type: | Power bank PCBA | Serve: | One-stop turnkey PCBA service |

| model: | JH-PCBA-017 | Testing service: | AOI X-Ray ICT function test |

| Function: | Prototype PCB Assembly | Supply capacity: | 60000 pieces per month |

| Packaging Details: | Bubble bag, pearl cotton bag, anti-static bag, vacuum bag | product name: | Mobile power charging circuit |

| Key words: | Mobile Power Circuit Module | Substrate: | FR4 |

| PCBA service: | SMD SMT DIP Assembly | Copper thickness: | 1 oz |

| brand: | Jinhua PCBA | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| MOQ: | 1 | Supplier type: | PCBAs |

| application: | Mobile power circuit 4.0 pcb assembly | Certificate: | ISO9001 |

| Origin: | Guangdong, China |

Our capabilities in consumer electronics PCB assembly cover the following areas:

1. Complex RoHS and non-RoHS PCBA

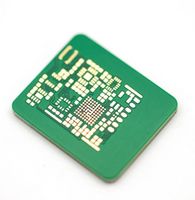

2. Multi-layer PCB with dense components

3. PTH, SMT & mixed process assembly

4. Single-sided and double-sided assembly

5. Component selection and BOM creation support

6. Mechanical assembly

7. Conformal anti-paint

8. Cable harness assembly

9. Comply with DFT and DFM guidelines

10. Strong testing protocols

our consumers Electronics PCB strictly adheres to customer requirements and strictly adheres to industry-leading standards. In fact, we have the following certifications and compliances that ensure we deliver performance-driven PCB assemblies to the consumer electronics industry:

Compliant with IPC and J-STD-001

|

Processing type: SMT surface mount THT/DIP plug-in/hand soldering mixed processing Finished product assembly

Test type: Visually X-ray inspection AOI automatic optical inspection function test |

Production equipment: SMT production line: 6 THT production line: 2

YAMAHA high-speed placement machine: 6 sets GKG Solder Paste Printer: 4 Jintuo reflow soldering machine: 2 sets Nitto wave soldering machine: 1

Hand Soldering Wires: 2 Function test line: 2 Conformal paint spraying machine: 1 |

Inspection and testing equipment: Areas of interest: 2 X-RAY BGA inspection machine: 1 set SINIC-TEK SPI: 1 Intelligent SMT first article inspection machine: 1 set Electron microscope (with measuring function): 2

other devices: Automatic PCB splitter: 6 sets Washing machine: 1 Forming machine: 2 |

|

Capacity:

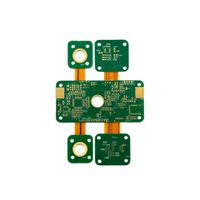

Assembled PCB types:Rigid PCB, flexible PCB, rigid-flexible PCB, aluminum substrate; Assembled PCB board size:Maximum 480X510mm; Minimum size: 50mm x 50mm; Minimal component:01005, 0201, 0402 Minimum BGA:Rigid PCB is 0.3mm pitch, PCB is 0.4mm pitch; Fine pitch components:0.3mm pitch Component height restrictions:15mm Assembly accuracy:+/-0.025mm

delivery time:Depending on quantity, from 24 hours to several weeks SMT production capacity:200-300 million chips/month THT production capacity:13 million chips/month Test ability:Depending on customer needs and product conditions |

||

Jinhua SMT workshop production line:

Jinhua DIP workshop production line:

-

Professional Adjustable Spectrum 6 Strips Lm301B Led Plant Light Strip Lm301B LED Plant Light Pcba

-

Reliable PCB Electronic Assembly Printed Circuit Boards and PCBA SMT Assembly Service in China

-

Welder Motherboard 220V MOS Tube Inverter Top Circuit Board Custom Printed PCB PCBA Service Assembly Manufacturer

-

OEM/ODM Home Appliance Electronic Industrial Control PCB & PCBA Circuit Board PCB Custom PCBA Assembly Manufacturer

-

Sample free one stop service pcba remote control pcba circuit board assembly pcba pcba service pcb pcb

-

Development and design of toy gun music sound integrated circuit chip, toy PCB assembly smart IC configuration speaker and components

-

4-Axis Drone Integrated Circuit Board Design Drone PCB Assembly Parts Sourcing PCBA Chip Assembly Drone Aircraft Motherboard

-

Apm Drone Pcb Board Toy Drone Circuit Boards Drone Flight Controller Pcb Agriculture

-

USB Phone Fast Charger Pcba PCB Assembly

-

Wall Charger 5V 1A 2A 3A USB mobile phone USB charger main PCBA PD power supply

Other Products

-

$0.10 - $3.50 / piece

$0.10 - $3.50 / piece -

$0.10 - $3.90 / piece

$0.10 - $3.90 / piece -

$0.10 - $3.50 / piece

$0.10 - $3.50 / piece -

$0.10 - $3.90 / piece

$0.10 - $3.90 / piece -

$0.10 - $3.90 / piece

$0.10 - $3.90 / piece -

$0.10 - $3.50 / piece

$0.10 - $3.50 / piece -

$0.10 - $3.90 / piece

$0.10 - $3.90 / piece -

$0.10 - $3.50 / piece

$0.10 - $3.50 / piece -

$0.10 - $3.50 / piece

$0.10 - $3.50 / piece -

$0.10 - $3.50 / piece

$0.10 - $3.50 / piece