China Electronics PCB/PCBA Supplier LED PCB Board Light

-

Supplier: Huizhou Linghangda Technology Co., Ltd. -

Region: GuangDong, China -

Contact: Mr Alan Liu -

Price: $1.00 / 1 - 99 pieces

$0.50 / 100 - 999 pieces

$0.10 / >=1000 pieces -

Min. Order: 1 piece

Product details

| Plate thickness: | 0.2-6mm | Maximum plate width: | 400mm |

| Minute line spacing: | 0.003'' | capacity: | 70 million impressions per month |

| Copper thickness: | 0.4-2mil (10-50um) | Biggest temper: | 399 degrees Celsius |

| Spray flux: | Add on | product name: | LED circuit board |

| speed: | 0.15 seconds/chip, 0.7 seconds/QFR | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| port: | Shenzhen Guangzhou Hong Kong | model: | Custom PCB and PCB Assembly |

| Application fields: | Automotive, medical, industrial, IOT, smart home, security equipment, | quality assurance: | AOI IQC PQC QA |

| Maximum board size: | 457 * 356 (18'' * 14'') | Wave soldering: | 2 |

| Surface treatment: | HASL/OSP/Ag/ENIG/ENEPIG/Immersion Silver/Tin | Board Dimensions: | custom |

| Origin: | Guangdong, China | Minute Hole Size: | 0.1mm(4mil) for HDI / 0.15mm(6mil) |

| Substrate: | FR-4/CEM-1/CEM-3/Polyimild/PTFE/Rogers | brand: | scraper technology |

| Supply capacity: | 70000 square meters per month | Packaging Details: | PCBA Gibson vacuum packaging or anti-static packaging Outer packaging: export carton or according to customer requirements. |

| Package preview: | Minute line width: | 0.075mm/0.075mm(3mil/3mil) |

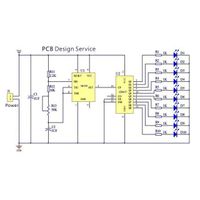

China Electronics PCB/PCBA Supplier LED PCB Board Light

the banner

Specification

PCBA capability

| patch line | 7 rows |

| capacity | 8 million impressions per day |

| board size | 680*550mm Min: 0.25"*0.25" |

| Minimum component size | 0201-54 sq.mm (0.084 sq.inch), long connector, CSP, BGA, QFP |

| speed | 0.15 seconds/chip, 0.7 seconds/QFP |

| wave soldering | Maximum printed circuit board width: 450mm |

| Minimum PCB width: unlimited | |

| Component height: top 120mm/bottom 15mm | |

| sweat welding | Metal Type: Partial, Whole, Inlay, Side Step |

| Metal material: copper, aluminum | |

| Surface treatment: gold-plated, silver-plated, tin-plated | |

| Air bag rate: less than 20% | |

| Crimp | Pressure range: 0-50KN |

| Maximum PCB size: 800*600mm | |

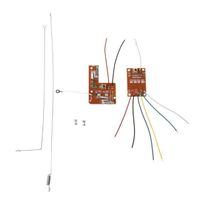

| Assembly type | SMT and through-hole |

| Solder type | Water Soluble Solder Pastes, Leaded and Lead Free |

| file format | Bill of Materials, Gerber files, Pick-N-Place files (XYRS) |

| Service type | Turnkey, Partial Turnkey or Consignment |

| Component packaging | Cutting tape, loose tube reels, parts |

| connecting time | 1-15 days |

| test | XRAY inspection, AOI inspection ICT, flying probe, burn-in, functional test |

exhibition

Advantage

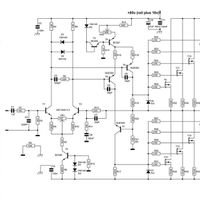

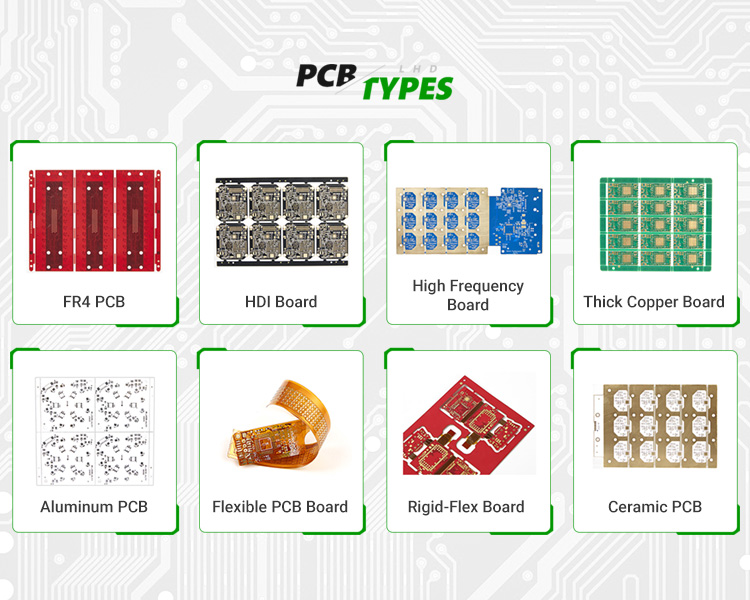

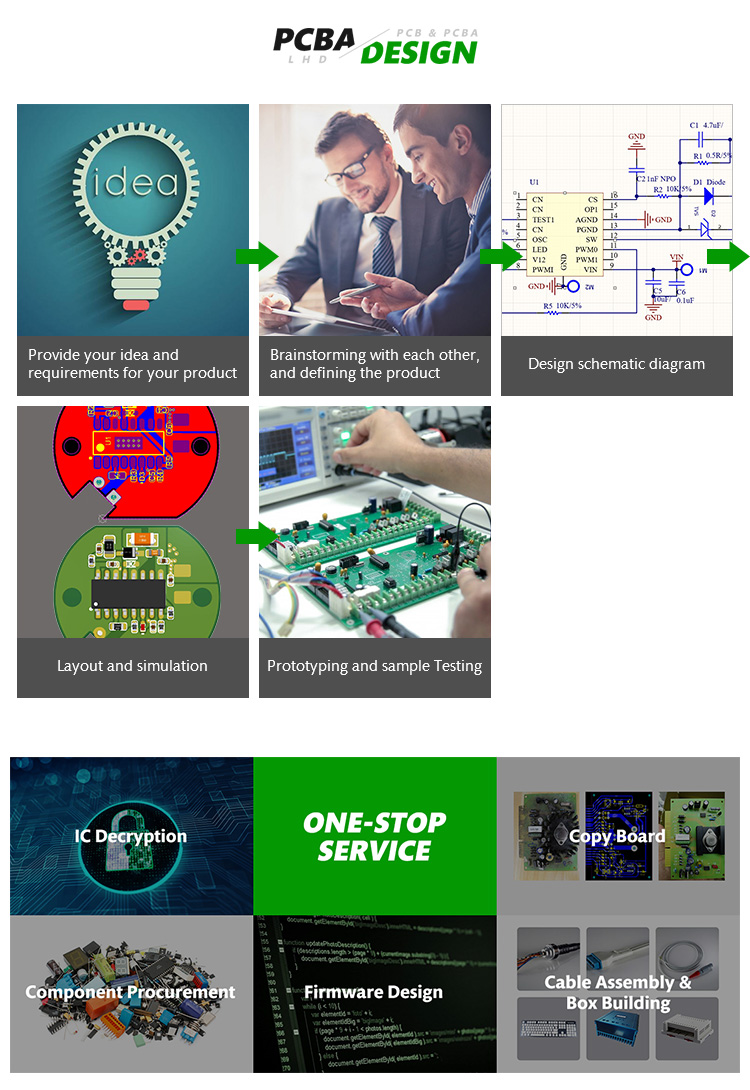

PCB/PCBA/Design

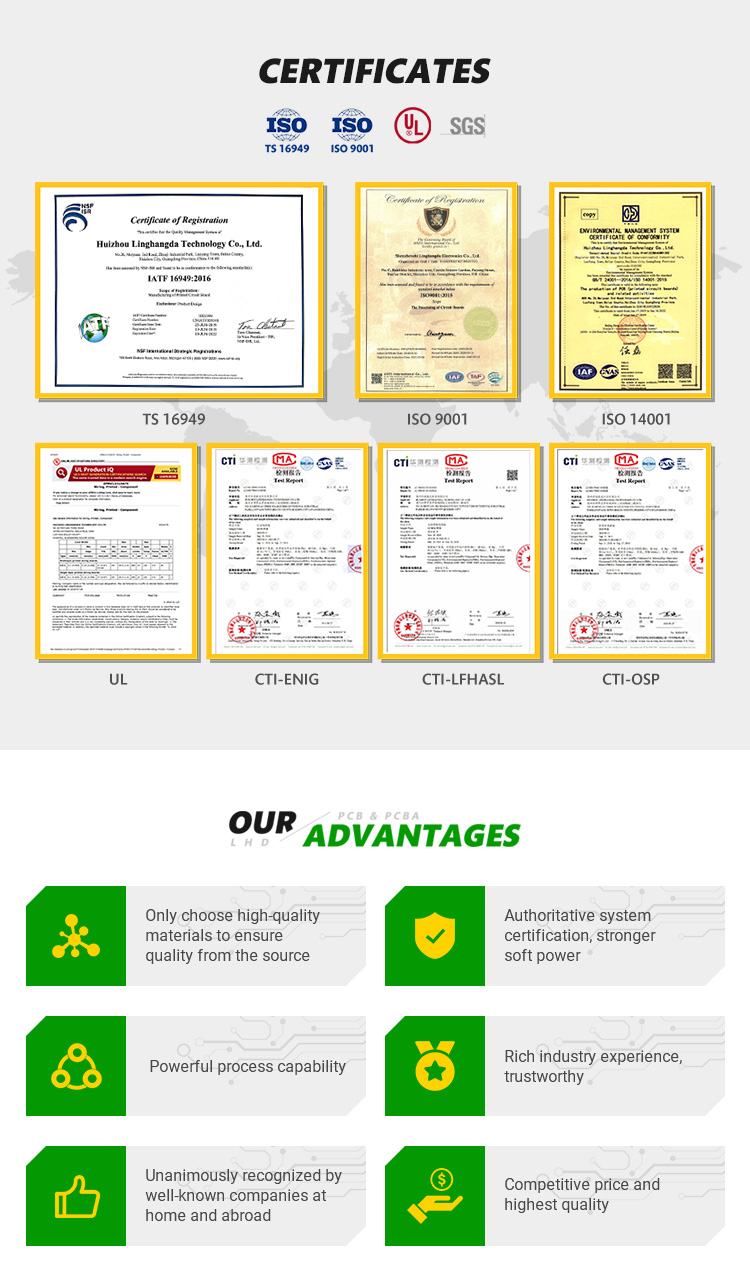

QC and partners

VIEW MORE

You may like

-

Jiabaida built-in BT BMS 7s 8s 10s 12s 13s 14s 24V 36V 48V 20A 30A automatically identifies BMS with UART NTC

-

Daly bms manufacturer pcb oem electric vehicle ev Lithium LI-ION 18650 Battery Pack 10S 36V 15A 20A BMS management system

-

Development board with LCD touch screen lcd lvds GPIO development board with Ethernet and USB interface driver board

-

USB interface PCB schematic layout engineer design service

-

4 Channel Remote Control 27MHz Circuit PCB Transmitter and Receiver Board with Antenna Radio System for Car Truck Toys

-

Schematic diagram of electronic circuit diagram of mobile power pcb board

-

R&D USB Charger PCBA Power Adapter PCB Assembly Smartphone Accessories Electronics Manufacturer

-

High Quality 9W High Voltage SMD 2835 AC220V LED Printing Round Paint LED Aluminum PCB for Tube Light

-

Custom BGA PCBA Supplier Professional Circuit Board Assembly Manufacturer PCB PCBA Fabrication Service Factory

-

Smart Electronics~DVB T2 ISDB-T ATSC pcb set top box high quality

Other Products

-

$0.10 - $10.00 / piece

$0.10 - $10.00 / piece -

$0.10 - $1.00 / piece

$0.10 - $1.00 / piece -

$0.10 - $1.00 / piece

$0.10 - $1.00 / piece