Transformer radiator forming and welding line

-

Supplier: Wuxi Haoshuo Technology Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Rene Chen -

Price: $350000.00 /set -

Min. Order: 1 set

| Local service location: | not any | brand: | HS |

| place of origin; place of origin: | Jiangsu, China | port: | Shanghai |

| Supply capacity: | 5 sets per quarter row | After warranty service: | Video technical support, online support, spare parts, on-site maintenance and repair services |

| State of health: | new | Showroom location: | not any |

| After-sales service provided: | On-site maintenance and repair services, on-site installation, commissioning and training, video technical support, online support | Packaging Details: | 5 pieces of 40GP containers are shipped naked by sea, the machine is fixed in the container with steel wire and wood blocks, and the machine is covered with a film to prevent dust |

| payment terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram | Main selling points: | automatic |

| Warranty: | 1 year | Applicable industries: | Energy and Mining, Manufacturing Plants |

| Total weight (T): | 80 |

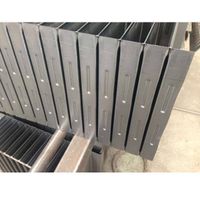

Transformer heat sink forming welding line

This production line is a fully automatic production line for the manufacture of transformer radiator panels. It is mainly composed of uncoiler, roll forming machine, spot welding machine, seam welding machine, head welding machine, trimming, head cutting and other parts. It is a high-tech production line for radiators, all processes are working automatically to ensure high quality.

Panel specifications: 320, 480, 520, 535mm

Panel length: 1500-4000mm

Working speed: 3-6m per minute

Control system: PLC automatic control, fully automatic

Electrical system: All electrical components adopt internationally renowned brand products

Total power: about 315Kw

Total area: 46.5 x 3.5m

Main machine components:

Hydraulic uncoiler

Main Roll Forming Machine

Pressing device

Output and flipping device

Servo feeding device

Multi-spot welder

seam welder

Head welding machine

trimming machine

cutting machine

Production line workflow:

Uncoiling--Rolling Forming--Indenter Cutting--Flipping Plate--Servo Feeding--Spot Welding

-- Board feeding -- Seam welding -- Board feeding -- Head welding -- Board feeding -- Trimming

-- Panel feeding -- Head cutting -- Product output

Main electrical components:

PLC: Mitsubishi/Delta/Siemens

VFD: Mitsubishi/Invoance/Delta

Touch screen: Invoance/Delta

Servo motor: Invoance/Mitsubishi

Welding machine controller: BOSCH

-

BW-1300 Transformer Oil Tank Fin Forming Machine Corrugated Fin

-

Transformer radiator forming welding line, transformer oil tank corrugated fin forming welding line

-

Fully automatic precision smart car air-conditioning relay production line

-

High efficiency hydraulic corrugated elbow forming machine for sale

-

2022 heat engine widened rolling shutter door panel rolling shutter door panel rolling door for sale

-

Fully automatic radiator corrugated fin wall forming welding machine

-

BW1600 transformer corrugated fin forming machine manufacturer

-

Transformer oil tank corrugated fin forming machine

-

Transformer oil tank corrugated fin forming machine

-

Efficient Automatic Downpipe Elbow Machine Cold Bending Forming Machine Plate Rolling Machine

Other Products

-

$100000.00 / set

$100000.00 / set -

$120000.00 / set

$120000.00 / set