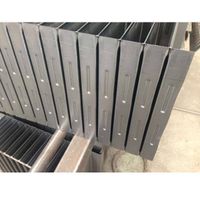

BW-1300 Transformer Oil Tank Fin Forming Machine Corrugated Fin

-

Supplier: Shandong Darling Machinery Equipment Co., Ltd. -

Region: Shandong, China -

Contact: Mr Martin Hoo -

Price: $98000.00 / 1 - 4 sets

$88000.00 / >=5 sets -

Min. Order: 1 set

| Warranty: | More than 5 years | Fin spacing (mm): | 40 |

| Molding speed: | 3 pieces/minute | Supply capacity: | Annual output of 300 corrugated fin forming machines |

| Fin height (mm): | 400 | product name: | Corrugated fin forming machine |

| Material: | SPCC, ST12, ST13, ST14 cold rolled plate | Package preview: | |

| Marketing type: | normal product | raw material: | SPCC, ST12, ST13, ST14 cold rolled plate |

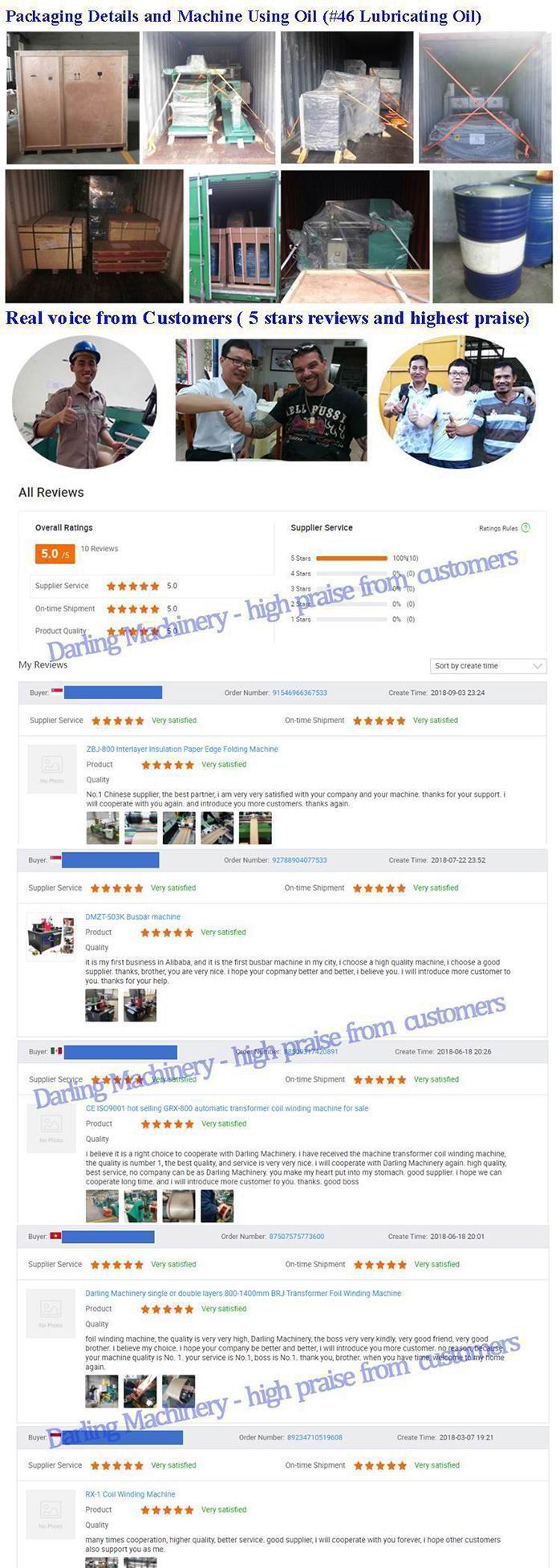

| Packaging details: | 1. Machine spare parts are packed in fumigation-free wooden boxes. 2. The main body is packed with waterproof film during transportation to prevent rust. 3. If there are special requirements, the entire car body can be packed into fumigation-free wooden boxes. Or make wooden pallets. 4. If necessary, we can go to the customer's factory to provide installation, debugging and training for our BW-1300 transformer tank corrugated fin forming machine | Main selling points: | competitive price |

| delivery time: | Corrugated fin forming machine 20-60 days | brand: | Darling Machinery |

| Core component warranty: | 3 years | Core components: | Programmable controller, motor |

| Total weight (tons): | 16 | Applicable industries: | Building material stores, machinery repair shops, manufacturing plants, construction engineering, others, energy and mining, transformer plants |

| Uncoiler loading: | 3-5 tons | Place of origin: | Shandong Province, China |

| Mechanical test report: | if | payment terms: | L/C, Western Union, D/P, D/A, T/T |

| Dimensions (length*width*height): | 18x2.1x1.8 meters | Steel plate thickness: | 1~1.75mm |

| Health status: | new | Strength Tendon Groove: | 2 slots |

| Ripple height: | Corrugated fin forming machine 50~500mm | application: | Transformer tank fan production |

| Material thickness (mm): | 1-1.75mm | port: | Qingdao Port corrugated fin forming machine |

| Steel plate width: | 300~1300mm | Video outbound inspection: | if |

| Total power (kW): | 45 | Material width (mm): | 1300 |

| Showroom location: | Kenya, Argentina, South Korea, Chile, United Arab Emirates, Colombia, Algeria, Romania, South Africa, Kazakhstan, Ukraine, Nigeria, Uzbekistan, Malaysia, Australia, Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Vietnam, Philippines, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Brazil | Corrugation pitch: | Corrugated fin forming machine ≥40mm |

| Type of machine: | Corrugating machine |

BW-1300 Transformer Oil Tank Corrugated Fin Forming Machine

Directly watch the machine working video (Video link):

Youtube: https://youtu.be/aTBajPM232o

QQ video: https://v.qq.com/x/page/q3215n0xtko.html

Baidu video: https://haokan.baidu.com/v?vid=4837981227745538508&bfe=1

The equipment is mainly composed of material unwinding mechanism, guide mechanism, hydraulic forming, hydraulic shearing, automatic welding and other components. The body is an all-steel welded structure.

Device parameters

|

thing |

code |

parameter |

|

raw material |

SPCC, ST12, ST13, ST14 cold rolled plate |

|

|

Steel plate width |

Second |

300~1300mm |

|

Steel plate thickness |

S |

1~1.75mm |

|

corrugation height |

H |

50~500mm |

|

corrugation pitch |

t |

≥40mm |

|

net gap between corrugations |

e |

6mm |

|

Number of corrugated belt groups |

nitrogen |

1~4 sets |

|

Corrugated tape length |

L |

≤2000mm |

|

Folding height |

C |

15~300mm |

|

Panel tip length (front clearance) |

Second |

≥40mm |

|

Panel tip length (back clearance) |

A |

≥40mm |

|

Corrugated fin rib groove |

|

Maximum 2 (according to customer requirements) |

|

Corrugated fin pitch error |

|

±0.25mm |

|

Molding speed |

|

≤20s (3-4 waves/minute) |

|

Total motor power |

|

45kW (including 2 welding machines) |

|

Voltage |

|

380V, three-phase, 50HZ |

|

gross weight |

|

20000kg |

|

construction area |

|

9000x6000(mm) |

|

Air source (prepared by customer) |

|

Pressure: 0.8Mpa, exhaust volume: 100L/min. |

|

unfold maximum load capacity |

|

6000kg |

|

Maximum loading capacity of feeding elevator |

|

6000kg |

|

Coil inner diameter range |

|

470-520mm (the unwinding machine shaft is hydraulically opened and retracted) |

|

Maximum coil diameter |

|

1000mm |

|

Unwinding machine speed |

|

12 rpm |

Main configuration

|

No. |

Name |

brand |

|

1 |

PLC |

Mitsubishi Japan |

|

2 |

Encoder |

Omron |

|

3 |

touchscreen |

Schneider or Xinjie |

|

4 |

Line guidance |

Taiwan/China famous brand HWIN |

|

5 |

The electromagnetic valve |

Northman |

|

6 |

pump components |

Rexroth |

|

7 |

cylinder |

Imported sealing ring |

|

8 |

Photoelectric switch |

Omron/Chinese famous brand |

|

9 |

air switch |

Schneider/Chinese famous brand |

|

10 |

AC contactor |

Schneider/Chinese famous brand |

|

11 |

Intermediate relay |

Schneider/Chinese famous brand |

|

12 |

Bearing |

SKF |

|

13 |

Pneumatic solenoid valve |

SMC/China famous brand |

|

14 |

servo motor |

Mitsubishi/Chinese famous brand |

|

15 |

Track, lead screw |

Taiwan HIWIN/China famous brand |

|

16 |

Welding machine |

Panasonic/Chinese famous brand |

our service

1. Pre-sale:We will provide you with professional guidance and help you purchase the right machine. When you choose our machine, you can get the maximum profit by using our machine.

2. In terms of sales:We will provide you with feedback on your order via photos and videos. Put your heart in your belly.

3. After-sales service:We will go to your factory to provide you with training and teach you how to use our machine, or we will provide you with video training. If there are our local agents and offices, we will let our local engineers come to your factory and provide you with training.

4. Our quality assurance:All our machines have a service life.

If you need local office support, please contact our company:

| Shandong Darling Machinery Equipment Co., Ltd. Address: Shacun Industrial Park, Licheng District, Jinan City Contact person: Martin Hoo +86-15253156158 (WhatsApp) Skype/WeChat: martinhoo936 QQ: 613252158 Website: www.darlingmachinery.com |

We will be the best partner

Although we live in different countries, our hearts are always together. we do not'We not only sell machines, but also services, technologies and brands. Once cooperation, forever friends!

Our cooperation is a win-win result.

® Our goals are:

By using our machines, you can produce better products and make more money!

FAQ:

1. Are you a manufacturing company or a trading company?

We have been manufacturing for more than 15 years, with 3 branch factories and over 10000 square meters.

2. How is your quality?

We only sell high-quality machines, and we use components from world-famous brands, such as SIEMENS, MITSUBISHI, DELEM, PANASONIC, SCHNEIDER, ABB, etc., so there is no need to worry about our quality.

3. How is your after-sales service?

We come to your factory for on-site training, or you can go to your local branch for training. If there is no request, we can provide you with video training through other methods.

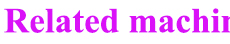

4. Why must we choose you as our supplier?

The real voice of customers is your best reference, 5-star customer feedback evaluation, 100% praise. These sounds allow you to work with us safely.

|

|

|

|

|

|

|

|

|

|

|

|

-

Transformer radiator forming welding line, transformer oil tank corrugated fin forming welding line

-

Fully automatic precision smart car air-conditioning relay production line

-

High efficiency hydraulic corrugated elbow forming machine for sale

-

2022 heat engine widened rolling shutter door panel rolling shutter door panel rolling door for sale

-

Fully automatic radiator corrugated fin wall forming welding machine

-

BW1600 transformer corrugated fin forming machine manufacturer

-

Transformer radiator forming and welding line

-

Transformer oil tank corrugated fin forming machine

-

Transformer oil tank corrugated fin forming machine

-

Efficient Automatic Downpipe Elbow Machine Cold Bending Forming Machine Plate Rolling Machine

Other Products

-

$108000.00 - $138000.00 / set

$108000.00 - $138000.00 / set -

$5000.00 / set

$5000.00 / set