Transformer oil tank corrugated fin forming machine

-

Supplier: Shanghai Trihope International Co., Ltd. -

Region: Shanghai, China -

Contact: Ms Vicky Li -

Price: $10000.00 /set -

Min. Order: 1 set

Product details

| Main selling points: | Sustainable | Warranty: | 1 year |

| Total power (kW): | 18 | Fin spacing (mm): | 45 |

| Packaging Details: | Standard packing or seaworthy packing | Dimensions (L*W*H): | 18000mm*3000mm*2600mm |

| Material Thickness (mm): | 1-1.5 | Video shipment inspection: | if |

| payment terms: | L/C, T/T, Negotiable | Feeding speed: | 0-28m/min |

| Supply capacity: | 1 set per month | Fin height (mm): | 50-400 |

| Corrugation pitch t: | ≥45mm | Marketing Type: | normal product |

| Total weight (T): | 17000 | Ripple height H: | 50-400mm |

| Bending height c: | 25mm or as customer's request | Showroom location: | not any |

| State of health: | new | Corrugated plate length L: | ≤2000mm |

| Clearance between corrugations e: | 6mm | Mechanical test report: | if |

| Number of corrugated board groups n: | 1-4 sets | Material width B: | 300-1300mm |

| brand: | three hopes | Material thickness S: | 0.5-1.5mm |

| Core components: | PLC, motor | Material: | steel |

| place of origin; place of origin: | China Shanghai | Applicable industries: | manufacturing plant |

| Material Width (mm): | 300-1300 | Shearing burrs: | Not more than 0.3mm |

| Core component warranty: | 1 year | port: | Shanghai |

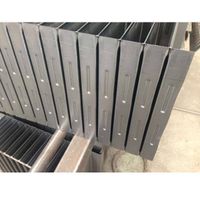

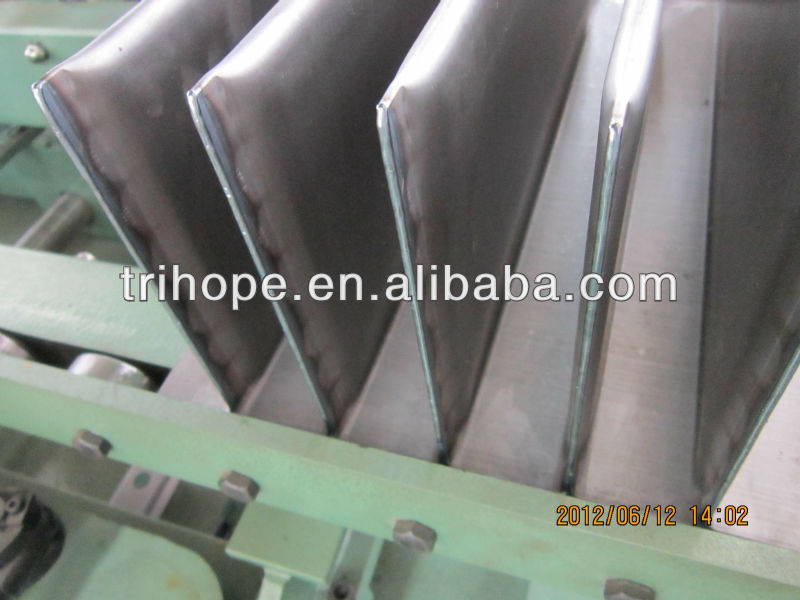

corrugation machine

I. Overview

1) Special machine for transformer oil tank.

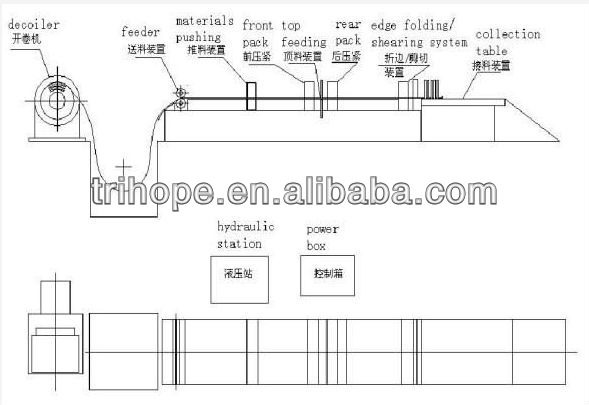

2) Including loading trolley, main engine, hydraulic station, electric control box, etc.

3) Reasonable structure and easy operation.

4) The hydraulic system is automatically controlled and the operation is stable.

5) Input all operating parameters into the screen to complete forming, cutting, bending and other processes at one time.

6) Main technical parameters

2. Main technical parameters

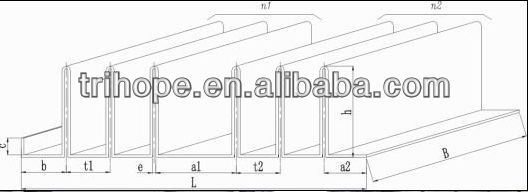

| 1. Processing range | |

| Material width B | 300-1300mm |

| Material thickness S | 0.5-1.5mm |

| Corrugation height H | 50-400mm |

| Corrugation pitch t | ≥45mm |

| Clearance between corrugations e | 6 mm |

| Number of corrugated board groups n | 1-4 sets |

| Corrugated plate length L | ≤2000mm |

| bending height c | 25mm |

| Front end of corrugated plate a | ≥25mm |

| Corrugated panel back end b | ≥25mm |

| Feeding speed | 0-28m/min |

| Forming speed | 30-25s/wave |

| system rate pressure | 10MPa |

| system maximum pressure | 14MPa |

| electricity: | AC three-phase four-wire 380V/50HZ (or according to customer requirements) |

| total electricity | 18KW |

| Machine size 18000mm*3000mm*2600mm | |

| 2. Loading trolley | |

| Maximum Loading Weight | 5000 kg (conventional configuration, can be met according to customer requirements) |

| Maximum up and down stroke | 350mm |

| table width | 540x1300 mm |

| up and down speed | 50mm/min |

| 3. Uncoiler | |

| Maximum Loading Weight | 5000 kg (normal configuration, according to customer requirements) |

| Unwinding speed | 0-28m/min |

| Uncoiler barrel diameter | 480-520mm |

| 4. Coil size | |

| the inside diameter of | 500 mm |

| outer diameter | 1000 mm |

| width | 300-1300mm (coil width greater than 1000mm outer diameter should be less than 930mm) |

| 5. Feeding system | |

| servo motor | 2 kW |

| Feeding speed | 0-28m/min |

| Feeding roller diameter | 114 mm |

| Feed roller width | 1400mm |

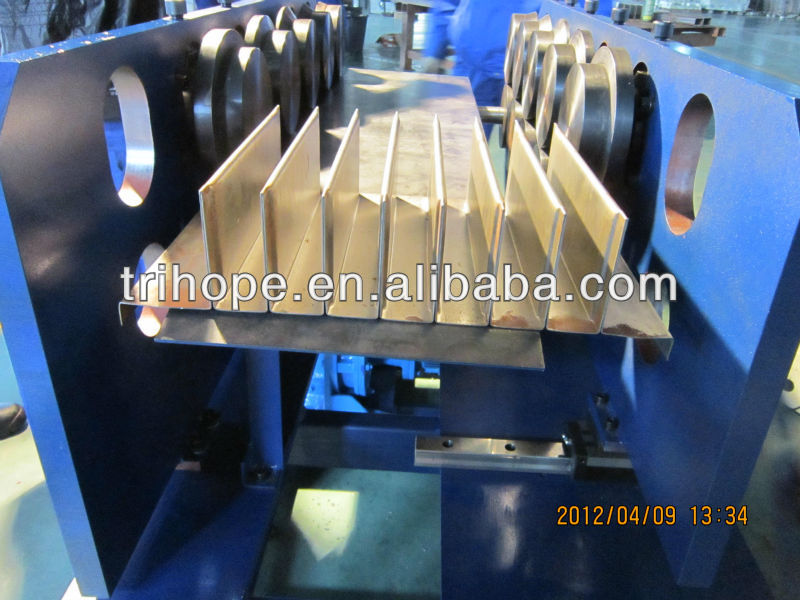

| 6. Front mold assembly | |

| dimension | 1300x410mm |

| Front and rear mold distance | 850 mm |

| Front mold lifting height | 20 mm |

| 7. Rear mold assembly | |

| Rear template size | 1470x500mm |

| Rear formwork lifting height | 410 mm |

| 8. Shear bending assembly | |

| scissors length | 1400 mm |

| Shear stroke | 420 mm |

| 9. Workbench | |

| size | 1400x2000mm |

3. Schematic diagram of the machine (FIG1), schematic diagram of corrugated sheet forming, machine photos

VIEW MORE

You may like

-

BW-1300 Transformer Oil Tank Fin Forming Machine Corrugated Fin

-

Transformer radiator forming welding line, transformer oil tank corrugated fin forming welding line

-

Fully automatic precision smart car air-conditioning relay production line

-

High efficiency hydraulic corrugated elbow forming machine for sale

-

2022 heat engine widened rolling shutter door panel rolling shutter door panel rolling door for sale

-

Fully automatic radiator corrugated fin wall forming welding machine

-

BW1600 transformer corrugated fin forming machine manufacturer

-

Transformer radiator forming and welding line

-

Transformer oil tank corrugated fin forming machine

-

Efficient Automatic Downpipe Elbow Machine Cold Bending Forming Machine Plate Rolling Machine

Other Products

-

$85000.00 - $89000.00 / set

$85000.00 - $89000.00 / set -

$5000.00 / set

$5000.00 / set

Related Search

Corrugated Fin Forming Machine

corrugated roll forming machine

water fiberglass oil tank machine

corrugated steel tile roof panel forming machine suppliers

oil tank cleaner machine suppliers

transformer oil vacuum drying machine

high precision transformer oil centrifuge machine

shot blast oil tank cleaning machine

cnc spring forming machine

plastic tray forming machine china sale