2022 heat engine widened rolling shutter door panel rolling shutter door panel rolling door for sale

-

Supplier: Botou Xinbo Import & Export Co., Ltd. -

Region: Hebei, China -

Contact: Mr Nate Bai -

Price: $4500.00 /piece -

Min. Order: 1 piece

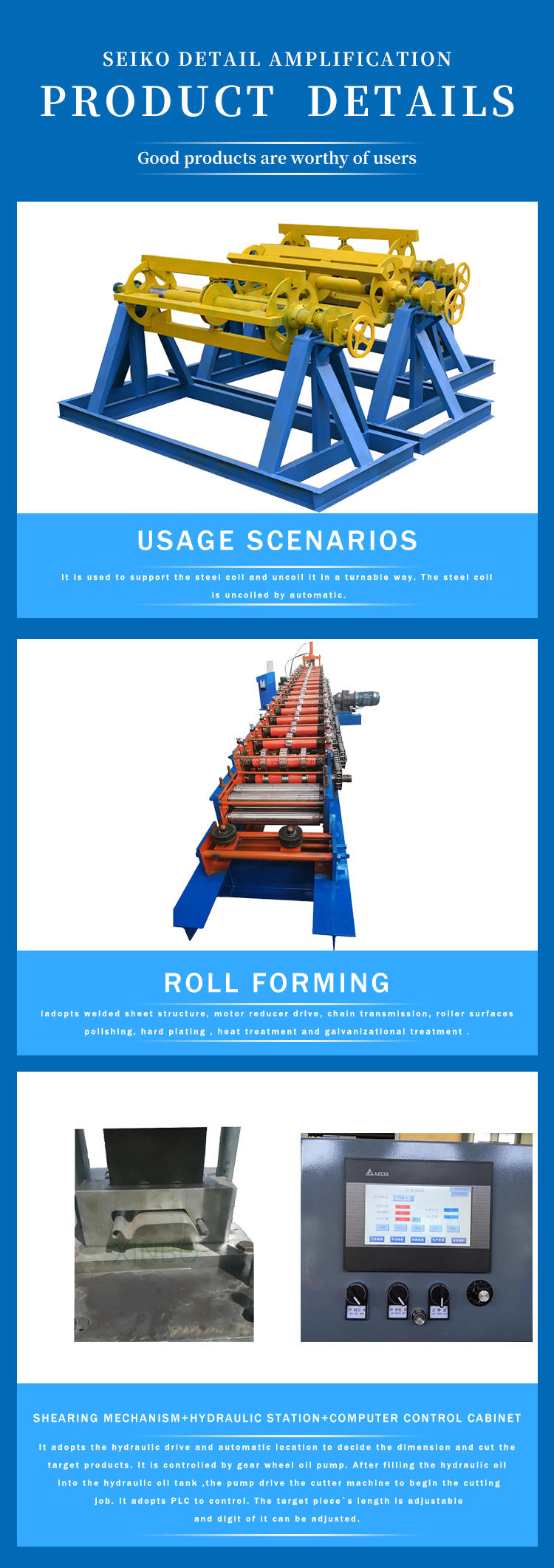

Product details

| brand: | new blog | Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump |

| Health status: | new | Mechanical test report: | if |

| Supply capacity: | 200 pieces per year | Dimensions (L*W*H): | About 5000x900x1430mm |

| Core component warranty: | 5 years | Main selling points: | Famous PLC |

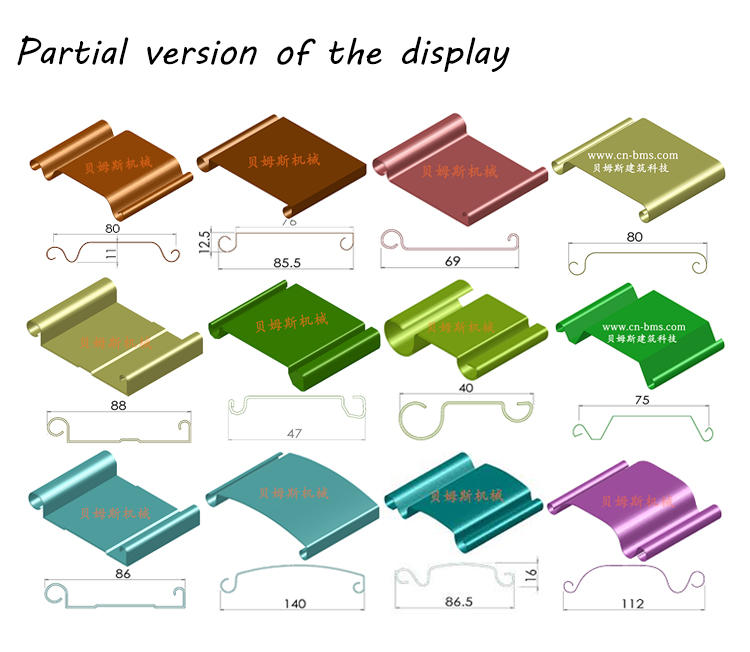

| Applicable industries: | Energy and Mining, Home Use, Printing Store, Food and Beverage Store, Farm, Retail, Restaurant, Food and Beverage Factory, Hotel, Construction Works, Food Store, Advertising Agency, Clothing Store, Building Materials Store, Machinery Repair Shop, Manufacturing Plant | Fin spacing (mm): | Design according to customer requirements |

| Fin height (mm): | Design according to customer requirements | Total power (kW): | 3KW |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Total weight (T): | 5 |

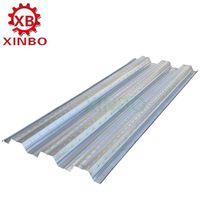

| Material: | galvanized | product name: | Corrugated fin forming machine |

| Warranty: | 5 years | Marketing Type: | New Products 2020 |

| Video shipment inspection: | if | Packaging Details: | The host is bare, and the computer control box is packed in a wooden frame. The main engine is packed in the container naked, and the computer control box is packed in a wooden box. |

| Material Width (mm): | Maximum 1.0mm | Showroom location: | Philippines, Saudi Arabia, Indonesia, Pakistan, India, South Africa |

| port: | Tianjin | Origin: | Hebei china |

Company Profile

Botou Xinbo Machinery Manufacturing Co., Ltd. is a professional manufacturer of roof panel/wall panel forming machines, CZ interchangeable purlin machines, floor forming machines, EPS/rock wool sandwich panel forming machines, rolling shutter door frame forming machines, and construction machinery products. factory. The testing equipment is complete and the technical force is strong.

With a wide range, high quality, reasonable prices and stylish designs, our products are extensively used in construction, living and other industries.

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships!Product parameters

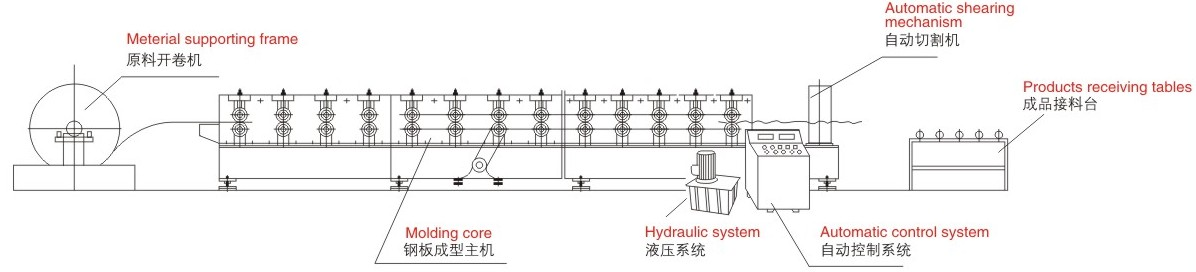

work process

Manual uncoiler---feed beach---roll forming machine---automatic shearing mechanism---computer control cabinet---feeding table

thing | Specification |

processing material | PPGI, GI, aluminum |

Input width(mm) | 100-200mm according to customer needs |

Forming width (mm) | According to customer needs |

Processing thickness (mm) | 0.28--0.8 According to customer needs |

Roller material | 45# steel, heat treatment |

Shaft diameter | Ф70mm |

Production speed | 12---15m/min according to customer needs |

Roller drive | Gear motor + chain drive |

cutting model | hydraulic profile cutting |

length measurement | Encoder |

control method | PLC control system (imported brand) |

operating mode | button + touch screen |

total power | 4+4kw/6kw/8kw design |

Voltage | 380V 50HZ or as buyer's request |

Number of roller stations | 14-20 row design |

User Feedback + Video Debugging

VIEW MORE

You may like

-

BW-1300 Transformer Oil Tank Fin Forming Machine Corrugated Fin

-

Transformer radiator forming welding line, transformer oil tank corrugated fin forming welding line

-

Fully automatic precision smart car air-conditioning relay production line

-

High efficiency hydraulic corrugated elbow forming machine for sale

-

Fully automatic radiator corrugated fin wall forming welding machine

-

BW1600 transformer corrugated fin forming machine manufacturer

-

Transformer radiator forming and welding line

-

Transformer oil tank corrugated fin forming machine

-

Transformer oil tank corrugated fin forming machine

-

Efficient Automatic Downpipe Elbow Machine Cold Bending Forming Machine Plate Rolling Machine

Other Products

-

$4500.00 / piece

$4500.00 / piece

Related Search

school bus doors for sale

re rolling mill for sale

heat transfer press machine roll press for clothing

outboard engine for sale us

new outboard engines for sale

250cc atv engines for sale suppliers

thailand engine generator for sale

lambo doors for peugeot 206

lab rolling mill for cosmetics

mini rolling mill for paint