High standard Automatic Highway guardrail board metal making machine for sale

-

Supplier: Henan Wadjay Machinery Co., Ltd. -

Region: China -

Contact: Mr dong peng -

Price: $15000.00 /piece -

Min. Order: 1 piece

Product details

Product Description

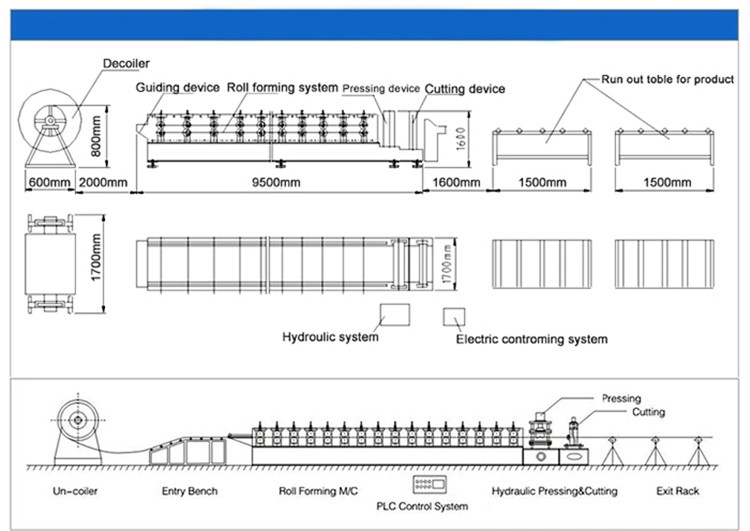

Instruction for guardrail protect panel roll forming machine.

Highway collision avoidance facilities, isolation and other facilities. Mainly used for traffic security projects such as

highways, primary and secondary roads, provincial roads, county roads and rural road scenic spots, large parking lots, etc.

highways, primary and secondary roads, provincial roads, county roads and rural road scenic spots, large parking lots, etc.

Features for guardrail protect panel roll forming machine.

1. The base material of the corrugated beam steel guardrail is made of steel, which is solid and durable.

2. The substrate of the corrugated beam steel guardrail is soaked in a hot-dip galvanizing pool, and a layer of zinc layer is adsorbed on the surface, so that the corrugated guardrail can play an electrochemical protection role and prevent the steel substrate from rusting from the inside to the outside. After polyester color powder coating, a permanent coating is formed, no matter what the environment, the corrugated beam steel guardrail will not rust, fade, chalk, fall off, and the color will be lasting and bright.

3. The corrugated beam steel guardrail adopts an assembled design, which is quick and simple to install.

4. The corrugated beam steel guardrail has good decorative properties and rich colors to meet the individual needs of different customers for products.

5. The corrugated beam steel guardrail is environmentally friendly, does not pollute the environment, and solves the problem of ordinary products polluting buildings.

6. The corrugated beam steel guardrail has good flexibility, and the rigidity and flexibility of the steel pipe make the guardrail product have better impact performance.

Specification

Product name | Highway guardrail roll forming machine |

Main motor power | 22KW with Cycloidal reducer |

Hydraulic station power | 5.5KW |

Hydraulic oil | 36#40# abrade oil |

Thickness of material | 3mm~4mm |

Electric tension | 380V 3phase 50HZ |

Material of roller | GCR15 Bearing Steel quenched HRC58-62, hard chrome coated 0.05mm |

Processing speed | 12-16m/min |

Processing precision | within 1.00mm |

Material of cutting blade | Cr12 Mov |

Transmission | Sprocket&Chain(1.5 inch) |

Roller station | 13 Rollers |

Product Specification

1. To design and make the best roll forming machine, we took EUROPEAN quality standard;

2. Choose the best material and components, and adopting our 17+ years experience;

3. We achieves that the machine capacity is double of the competitors;

4. Very easy to install and operate the roll forming machine.

2. Choose the best material and components, and adopting our 17+ years experience;

3. We achieves that the machine capacity is double of the competitors;

4. Very easy to install and operate the roll forming machine.

Workshop Overview

Details Images

#Uncoiler

Glazed roll forming machine load parts, decoiler loading frame we can offer different type can choose. standard type are manual, also can choose electric loading frame or hydraulic loading frame.

This loading frame decoiler also can use in other type machine, customer can buy it alone. decoiler type can be 5 ton decoiler, 8 ton decoiler,10ton decoiler

This loading frame decoiler also can use in other type machine, customer can buy it alone. decoiler type can be 5 ton decoiler, 8 ton decoiler,10ton decoiler

#Machine Frame

Glazed tile roll forming machine adopts welded steel frame structure, it make sure roof sheet machine can operation more stable

AC frequency conversion motor reducer drive, chain transmission, roller surfaces polishing,

hard plating, heat treatment and chrome coating.

AC frequency conversion motor reducer drive, chain transmission, roller surfaces polishing,

hard plating, heat treatment and chrome coating.

#Forming roll and hydraulic station

Glazed tile roll forming machine forming roll quality will decide roof sheet shapes, we can according to your local roof shape

customized different type rollers

Roller chrome coated thickness: 0.05 mm

Roller material: Forging Steel 45# heat treatment.

customized different type rollers

Roller chrome coated thickness: 0.05 mm

Roller material: Forging Steel 45# heat treatment.

#Control Part

Glazed tile roll forming machine control parts have different types, standard type are button control, through press buttons to

realize different function.

PLC touch screen type can setting data on the screen, its price is little higher, but is more intelligent and automatic.

realize different function.

PLC touch screen type can setting data on the screen, its price is little higher, but is more intelligent and automatic.

Packing & Delivery

1. Packing type:wooden case,also be packaged according to customer requirements.

2. We will send photos and videos for your reference before shipment.

VIEW MORE

You may like

-

Three-layer molding machine

-

Low cost clay brick making machine manual type clay brick making machine suitable for different sizes and different types of bricks

-

1000 type roof panel glazed tile pressing machine

-

HMS900 Electric Tile Cutter with CE Certification 1000mm Cutting Length, Marble Saw

-

Sheet metal building materials manufacturing machinery parts

-

Wall and color steel tile type polyurethane sandwich roof panel manufacturing machine

-

Terrazzo brick press

-

2022 Popular Manual Clay Roof Tile Making Machine Floor Tile Making Machine Roof Floor Tile Press Forming Machine

-

Galvanized floor deck forming machine

-

Automatic metal Ibr shingle trapezoidal shingle roller press machine for sale in South Africa

Other Products

-

$21900.00 / piece

$21900.00 / piece -

$6590.00 / piece

$6590.00 / piece -

$7500.00 / piece

$7500.00 / piece -

$450.00 / piece

$450.00 / piece -

$1500.00 / piece

$1500.00 / piece -

$8000.00 / piece

$8000.00 / piece -

$11000.00 / piece

$11000.00 / piece -

$430.00 - $530.00 / set

$430.00 - $530.00 / set

Related Search

scrap metal baler machine for sale

toothpick making machine for sale

cnc used sheet metal bending machine for sale

z94 4c nail making machine for sale

automatic corrugated box making machine for corrugation machine

button making machine for garments

charcoal pellet make machin for carbon black suppliers

automatic transformer coil winding machine for sale

making machine for pvc pipe

pellet making machine for wood