Ibr Trapezoidal roof glazed tile corrugated roofing sheet making machine

-

Supplier: Henan Wadjay Machinery Co., Ltd. -

Region: China -

Contact: Mr dong peng -

Price: $7500.00 /piece -

Min. Order: 1 piece

Product details

Product Introduction

Pls contact us for specific parameters

We are professional manufacturers, product quality and price are guaranteed

(Other design of tile making roll forming machine, we also could customized to you, just share us your details about: )

1)Your details design of tile making roll forming machine.

2)Raw materials of tile making roll forming machine

3)Thickness of tile making roll forming machine

(Other design of tile making roll forming machine, we also could customized to you, just share us your details about: )

1)Your details design of tile making roll forming machine.

2)Raw materials of tile making roll forming machine

3)Thickness of tile making roll forming machine

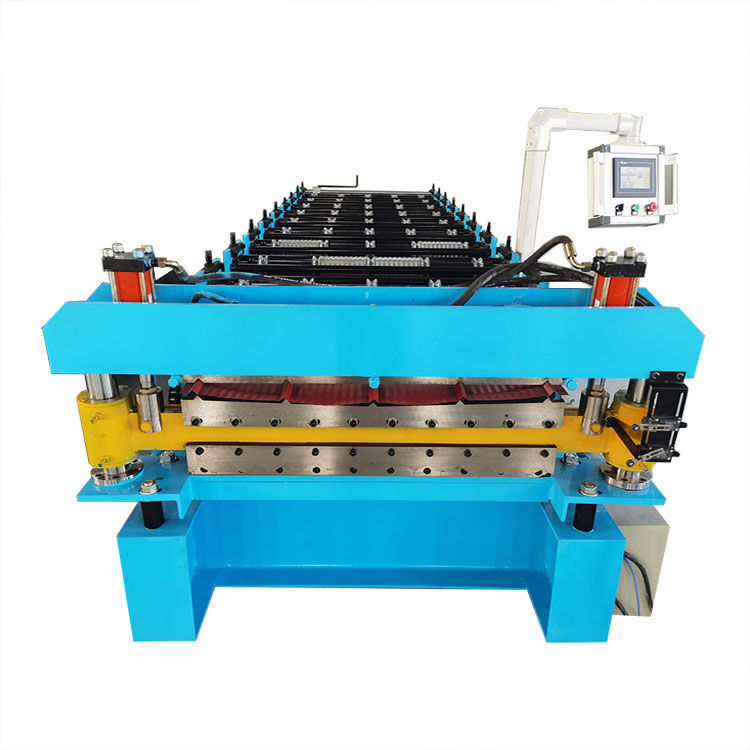

Automatic Color Steel Roll Forming Machine IBR Profile Roof Sheet Tile Making Machinery Price is a machine composed of unwinding, forming, and post-forming cutting. Its color plate has a flat and beautiful appearance, uniform paint patterns, high strength, and durability.

It is widely used in industrial civil buildings, such as factory buildings, warehouses, stadiums, exhibition pavilions, theaters and other rooms and walls.

Product Parameter

Contact us for more details

Raw Material | feeding width | 1200MM |

effective width | 1000MM | |

thickness | 0.3-0.8MM | |

Main Roll Forming Machine | roller material | 45# steel plated with chrome |

diameter of shaft | 70MM | |

roller station | 16MM | |

Main Configuration | main motor power | 5.5kw |

hydraulic station power | 4kw | |

control system | PLC |

Product Detail

Contact us for more details

- PCL control of tile making roll forming machine

PLC have different processing can be customized, like Simens, Schneider, Omron etc.

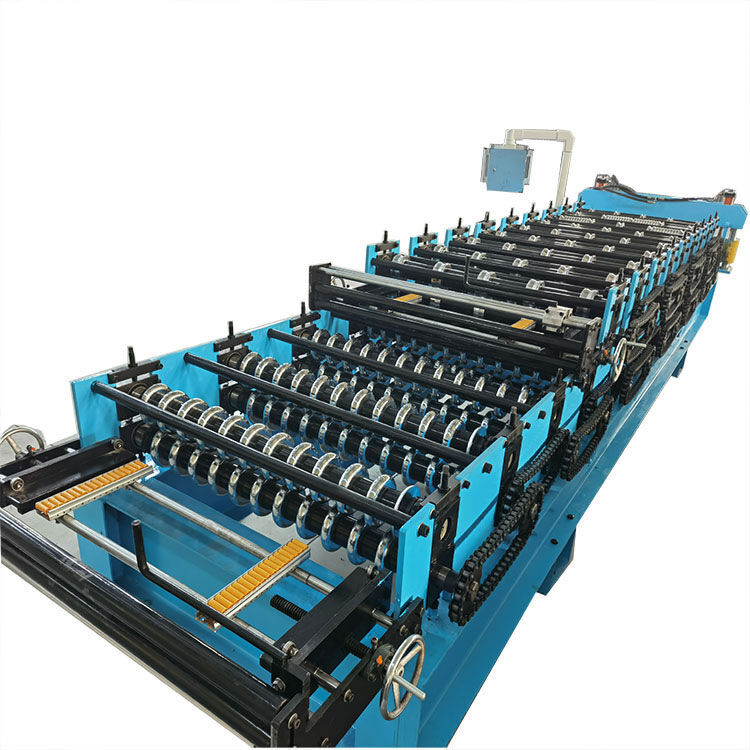

- Robber roller of tile making roll forming machine

Drive mode: 1inch chain

Sidewall:14mm 45# steel plate

Material of rollers: 45# forging steel

Material of shafts: 45# steel with finish turning

Diameter of shafts: φ60mm

Number of rollers : 11rollers

Sidewall:14mm 45# steel plate

Material of rollers: 45# forging steel

Material of shafts: 45# steel with finish turning

Diameter of shafts: φ60mm

Number of rollers : 11rollers

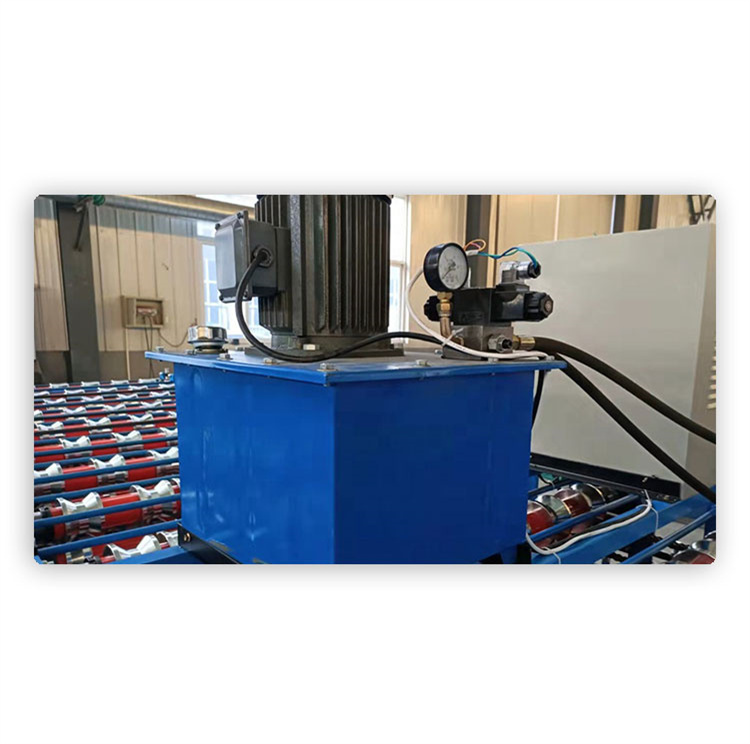

- Hydraulic Station of tile making roll forming machine

After filling the hydraulic oil into the hydraulic oil tank, the pump drives the cutter machine to begin the cutting job.

Power: 3kw

Power: 3kw

Product Feature

Contact us for more details

1. This roll forming machine can roll form metal roofing sheet. After roll formed by this roll forming machine, the surface will be very smooth and beautiful without any scratch on surface.

2. Roll forming process: uncoiler, roll forming, forming step effect, cut to length.

3. Fully Automatic Control System with PLC.

4. Easy operation: Key in the length and quantity on the control panel.

5. We also can do a custom roll forming machine, We can design the machine according to your specification and profile drawing.

2. Roll forming process: uncoiler, roll forming, forming step effect, cut to length.

3. Fully Automatic Control System with PLC.

4. Easy operation: Key in the length and quantity on the control panel.

5. We also can do a custom roll forming machine, We can design the machine according to your specification and profile drawing.

More Product

Select according to need

VIEW MORE

You may like

-

Three-layer molding machine

-

Low cost clay brick making machine manual type clay brick making machine suitable for different sizes and different types of bricks

-

1000 type roof panel glazed tile pressing machine

-

HMS900 Electric Tile Cutter with CE Certification 1000mm Cutting Length, Marble Saw

-

Sheet metal building materials manufacturing machinery parts

-

Wall and color steel tile type polyurethane sandwich roof panel manufacturing machine

-

Terrazzo brick press

-

2022 Popular Manual Clay Roof Tile Making Machine Floor Tile Making Machine Roof Floor Tile Press Forming Machine

-

Galvanized floor deck forming machine

-

Automatic metal Ibr shingle trapezoidal shingle roller press machine for sale in South Africa

Other Products

-

$21900.00 / piece

$21900.00 / piece -

$15000.00 / piece

$15000.00 / piece -

$6590.00 / piece

$6590.00 / piece -

$450.00 / piece

$450.00 / piece -

$1500.00 / piece

$1500.00 / piece -

$8000.00 / piece

$8000.00 / piece -

$11000.00 / piece

$11000.00 / piece -

$430.00 - $530.00 / set

$430.00 - $530.00 / set

Related Search

corrugated roof sheet making machine

corrugated roofing sheets making machine

roofing sheet making machine

roofing sheets manufacturing machines

120 trailer mounted roof sheet forming machine

plastics sheets making machine

glass sheets making machine

pvc sheet making machine

epe sheet making machine

epe foam sheet making machine