Centrifugal Milk Cream Separator Machine Auto Dairy Degrease Separator Clarifier Equipment Cheap price

-

Supplier: Liaoyang Shenzhou Machinery Equipment Co., Ltd. -

Region: China -

Contact: Ms Cathy X -

Price: $9800.00 /piece -

Min. Order: 1 piece

Product details

Product Description

Centrifugal Milk Cream Separator Machine Auto Dairy Degrease Separator Clarifier Equipment Cheap price

In the industrial production of milk products, the requirements for milk are different due to different products. Therefore, there are requirements for clean or skimmed milk. As milk has gradually become one of the indispensable foods in people's daily life. People's requirements for skimming milk are getting higher and higher. To ensure the quality of degreasing, the higher the requirements for the degreasing effect of the milk separator.

Disc separator, called dish centrifuge as well, is a kind of advanced automatic machine with high efficiency and large output, and can be applied for liquid separation in pharmaceutical, food, chemical, biological products, beverage products and other industries. With new automatic control, this advanced disc separator is superior to other separator, to achieve ideal separation effect by producing different centrifugal force onto materials in different proportion, which make it more suitable for suspension with low solid content ,and mutually insoluble liquid with a smaller specific gravity.

In addition, Disc separator is also be used for regenerating lubricating oils and purifying fuel used on ships or on-land electric stations. It can quickly separate water and impurity from the oil to ensure the regular operation of machines.In the centrifugal force field, different materials will be settled down at different velocity according to their respective attribute, thus separating impurities. The mixture in the high speed rotor drum will form a cirque. From the outside to the inside, the materials lay according to their different density. For the centrifugal force is more than gravity, centrifugal separation work when gravity separation does not.

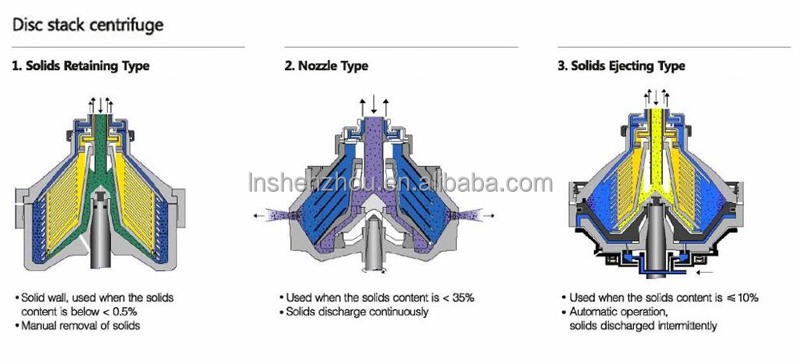

According to different separation methods, the whole series of disc separators can be divided into three-phase disc separator (DHY) for liquid-liquid -solid separation and two-phase separator (for liquid-solid separation) disc separator (DHC). and according to different methods in slag discharge, the auto slog discharging disc separator can be divided into manual automatic slag discharge disc separator and the PLC system fully controlled automatic slag discharge disc separator. Disc separator according to the internal slagging different ways, the disc separator can be divided into piston-type slag discharge disc separator and nozzle-type slag separator, In general, the mode of slag discharge can be selected according to the characteristics of the material!

In addition, Disc separator is also be used for regenerating lubricating oils and purifying fuel used on ships or on-land electric stations. It can quickly separate water and impurity from the oil to ensure the regular operation of machines.In the centrifugal force field, different materials will be settled down at different velocity according to their respective attribute, thus separating impurities. The mixture in the high speed rotor drum will form a cirque. From the outside to the inside, the materials lay according to their different density. For the centrifugal force is more than gravity, centrifugal separation work when gravity separation does not.

According to different separation methods, the whole series of disc separators can be divided into three-phase disc separator (DHY) for liquid-liquid -solid separation and two-phase separator (for liquid-solid separation) disc separator (DHC). and according to different methods in slag discharge, the auto slog discharging disc separator can be divided into manual automatic slag discharge disc separator and the PLC system fully controlled automatic slag discharge disc separator. Disc separator according to the internal slagging different ways, the disc separator can be divided into piston-type slag discharge disc separator and nozzle-type slag separator, In general, the mode of slag discharge can be selected according to the characteristics of the material!

Feature:

Features

* High speed centrifugation to remove oil grease and sludge impurities

* Strong emulsification ability

* Low energy consumption,saves money

* Full automation possible with PLC automatic control panel.

* Centrifugal separation requiring no filter media.

* High reliability drive train system backed by delivery of over 1,000 units a year.

* Bowl design with superior separation performance and with good response to discharge loads.

* Pilot valve regulates total/partial discharge of solids.

* Super partial discharger (option) minimizes liquid loss and maximizes thickening of solid

* Fraction for discharge.

* Vibration-proof design realizes long working life.

* High speed centrifugation to remove oil grease and sludge impurities

* Strong emulsification ability

* Low energy consumption,saves money

* Full automation possible with PLC automatic control panel.

* Centrifugal separation requiring no filter media.

* High reliability drive train system backed by delivery of over 1,000 units a year.

* Bowl design with superior separation performance and with good response to discharge loads.

* Pilot valve regulates total/partial discharge of solids.

* Super partial discharger (option) minimizes liquid loss and maximizes thickening of solid

* Fraction for discharge.

* Vibration-proof design realizes long working life.

Working Principle

How does Disc Separator work?

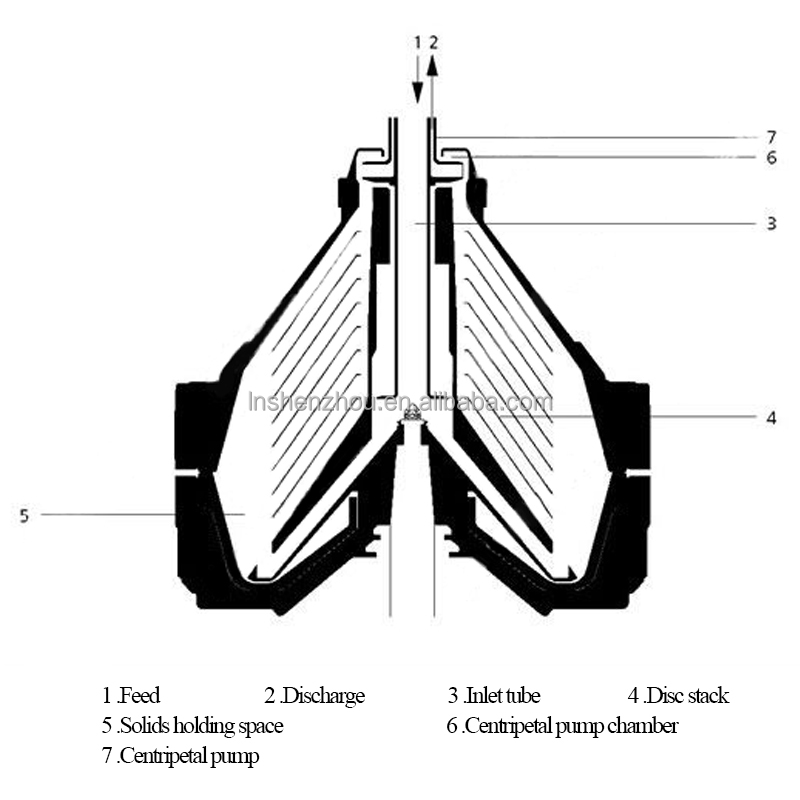

The disc separator is in vertical structure. The drum is mounted on the upper end of the vertical axis, which is driven by a motor and rotates at a high speed. There is a set of disc - shaped parts that are stacked together in the drum, with a small gap among them. When the suspension (or emulsion), which is pumped into the drum by feeding tube located in the center of the drum, pass through the gap between the discs, solid particles (or droplets) would settle down to form sediment (or liquid layer) on the disc by centrifuge force, and then the sediment slid along the surface of the disc and separated from the disc to accumulate in the largest diameter of the drum. At last, the separated liquid discharged from the outlet. The disc is utilized to shorten the settling distance of solid particles or droplets, enlarge the settlement area of the drum, and improve the production capacity of the separator. The solids accumulated in the drum are removed from the drum by manual after the machine stop, or out of the drum in the case of a dregs machine without stopping.

The disc separator is in vertical structure. The drum is mounted on the upper end of the vertical axis, which is driven by a motor and rotates at a high speed. There is a set of disc - shaped parts that are stacked together in the drum, with a small gap among them. When the suspension (or emulsion), which is pumped into the drum by feeding tube located in the center of the drum, pass through the gap between the discs, solid particles (or droplets) would settle down to form sediment (or liquid layer) on the disc by centrifuge force, and then the sediment slid along the surface of the disc and separated from the disc to accumulate in the largest diameter of the drum. At last, the separated liquid discharged from the outlet. The disc is utilized to shorten the settling distance of solid particles or droplets, enlarge the settlement area of the drum, and improve the production capacity of the separator. The solids accumulated in the drum are removed from the drum by manual after the machine stop, or out of the drum in the case of a dregs machine without stopping.

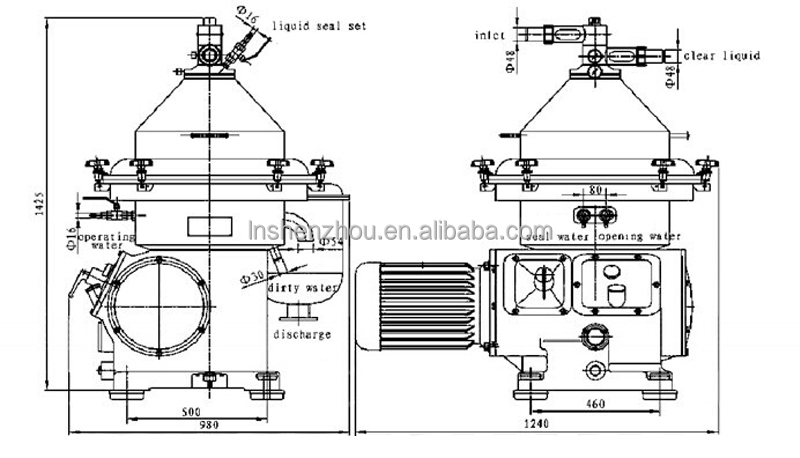

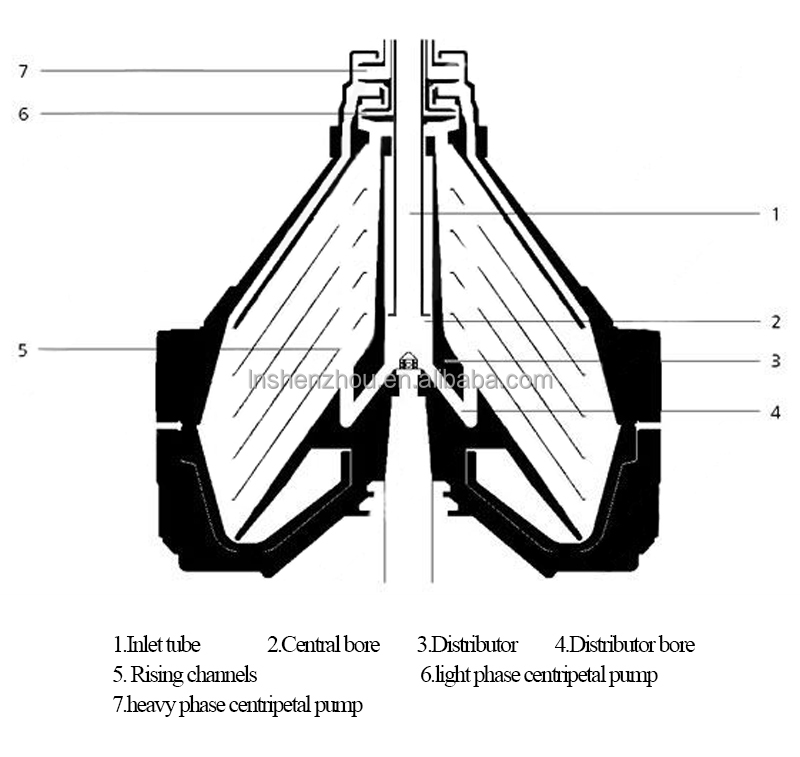

Main Structure

Powerful Motor provide power through the thermal coupling to drive drum in high-speed rotating around the main axis. And the liquid material is carried by feeding pipe located in the upper center into the bottom of the drum, and then led in the porthole below the disc and driven to the drum wall. Under centrifugal force, solid- liquid-liquid do the below motion to complete thorough separation:solid phrase, which is heavier than liquid, would sink into the inner wall of the drum for sediment formation; light liquid flow in centripetal pump, and be discharged by liquid outlet; The heavy liquid tends to the drum wall along the cone inside the disc, and then flows upward through through the heavy liquid concentric pump to be discharge from the outlet.

Due to the double-conical design of the inner cavity of the drum, it can compress the slag and increase its concentration.

Besides, some nozzles is mounted around the drum to spray slurry sediment, whose number and aperture are determined on the properties of the suspension, the degree of concentration and the amount of treatment.

In order to improve the slag concentration, recovery device is configured with this disc separator to the discharged sediment for reuse. For the solid concentration of the slag can be increased by 5~20 times than that of the feeding materials.

The processing capacity of the separator is up to 30t/h, which is suitable for suspension with solid phrase in diameter of 0.1~100 microns and concentration less than 10% (maximum to 25%).

Besides, some nozzles is mounted around the drum to spray slurry sediment, whose number and aperture are determined on the properties of the suspension, the degree of concentration and the amount of treatment.

In order to improve the slag concentration, recovery device is configured with this disc separator to the discharged sediment for reuse. For the solid concentration of the slag can be increased by 5~20 times than that of the feeding materials.

The processing capacity of the separator is up to 30t/h, which is suitable for suspension with solid phrase in diameter of 0.1~100 microns and concentration less than 10% (maximum to 25%).

Application Case:

For repeatedly tests, Disc Separator is mainly used for liquid-solid separation, among which, content of solid phase is within 1%-5% and diameter of solid particles is more than 0.5 microns.

1. oil products: the separation and clarification for vegetable oil, animal oil, fish oil, crude oil, all kinds of fuel oil,

ubricating oil,and clarification of dairy products;

2. food: juice clarification, beer separation, broth separation and clarification for fermentation broth in fermented brewery;

3. pharmaceuticals: extraction of vaccines, mycelium, glucose, insulin, antibiotics, vitamins;

4.chemical industry: recovery for dry cleaning agent solvent, zinc plating solution, aluminum sulfate solution, tar water mixture, polyvinyl chloride, polypropylene, polyethylene, silver (film processing) and catalyst and magnetite .

5. Chinese medicine: the separation and clarification of plant extract.

1. oil products: the separation and clarification for vegetable oil, animal oil, fish oil, crude oil, all kinds of fuel oil,

ubricating oil,and clarification of dairy products;

2. food: juice clarification, beer separation, broth separation and clarification for fermentation broth in fermented brewery;

3. pharmaceuticals: extraction of vaccines, mycelium, glucose, insulin, antibiotics, vitamins;

4.chemical industry: recovery for dry cleaning agent solvent, zinc plating solution, aluminum sulfate solution, tar water mixture, polyvinyl chloride, polypropylene, polyethylene, silver (film processing) and catalyst and magnetite .

5. Chinese medicine: the separation and clarification of plant extract.

Specification

|

||||||||||||||||||||||||||||||||||||||||||||||||

Company Profile

Liaoyang Shenzhou Machinery Equipment Co., Ltd is a professional for supplier of pharmaceutical and chemical machine in China.We have a well-experienced team and a professional design institute,With rich experiences in pharmaceutical machinery and equipment including packing machine, centrifuge, falling film evaporator, distillation,mixer, tablet press machine, suppository production line,dryer,capsule filling machine ,capsule and so on.Our products are exported to many countries and areas, such as the USA, Korea, India, Indonesia,Thailand, Vietnam,Japan, Denmark,Romania, Bulgaria,Russia,South Africa, and so onAt the same time,our product with best prices and good quality,welcome to Shenzhou!

Packing & Delivery

wooden case

FAQ

1. who are we?

We are based in Liaoning, China, start from 1980 sell to South America(12.00%),Southeast Asia(10.00%),Northern Europe(10.00%),Southern Europe(10.00%),Domestic Market(10.00%),South Asia(8.00%),Central America(6.00%),North America(5.00%),Eastern Europe(5.00%),Africa(5.00%),Oceania(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Mid East(4.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Centrifuge,Separator,Packing machine,Drying machine,Filling & Sealing machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian

We are based in Liaoning, China, start from 1980 sell to South America(12.00%),Southeast Asia(10.00%),Northern Europe(10.00%),Southern Europe(10.00%),Domestic Market(10.00%),South Asia(8.00%),Central America(6.00%),North America(5.00%),Eastern Europe(5.00%),Africa(5.00%),Oceania(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Mid East(4.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Centrifuge,Separator,Packing machine,Drying machine,Filling & Sealing machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian

VIEW MORE

You may like

-

PSB800 vertical centrifuge uses centrifugal force to clean waste oil, top feeding and unloading

-

Plastic Coconut Oil Pipe Separator Centrifuge Tube Stainless Steel Made in China

-

All stainless steel 450 filter vibrating screen/soy milk machine liquid vibration filter with cart

-

Liquid-solid separator DAF biogas dissolved air flotation for other water treatment equipment

-

Bread Brewer's Yeast Disc Centrifuge with Nozzle (Nozzle Centrifuge)

-

Hot aluminum ash separator to process 700 degrees Celsius aluminum ash

-

Innovative solid decanter centrifuge

-

Laboratory economical/low price disc centrifuge

-

Large Capacity High Quality Cannabis Extraction Centrifuge

-

2018 honey centrifuge extractor and bee centrifuge honey machine

Other Products

-

$16800.00 / piece

$16800.00 / piece -

$3980.00 / piece

$3980.00 / piece -

$3980.00 / piece

$3980.00 / piece -

$3980.00 / piece

$3980.00 / piece -

$3980.00 / piece

$3980.00 / piece -

$3980.00 / piece

$3980.00 / piece -

$3980.00 / piece

$3980.00 / piece -

$13900.00 / piece

$13900.00 / piece -

$13900.00 / piece

$13900.00 / piece -

$350.00 / piece

$350.00 / piece

Related Search

milk cream separator machine

milk cream separator

ice cream soft machine

commercial gelato ice cream making machine

gelato hard ice cream pasteurization machine

ice cream sticks machine importer suppliers

ice cream making machine

cream ice machine

small milk powder making machine

creame making machine used suppliers