GQ105J Tubular centrifuge separator for waster oil

-

Supplier: Liaoyang Zhonglian Pharmaceutical Machinery Co., Ltd. -

Region: Liaoning, China -

Contact: Ms Emily Peng -

Price: $6000.00 /unit -

Min. Order: 1 unit

Product details

| Supply Ability: | 100 Units per Year GQ105J Printing Ink Purify Tubular Centrifuge Separator; | Type: | Centrifuge; |

| Warranty of core components: | 1 Year; | Applicable Industries: | Food & Beverage Factory,Energy & Mining; |

| Marketing Type: | Hot Product 2019; | Condition: | New; |

| After-sales Service Provided: | Free spare parts; | Key Selling Points: | Famous brand PLC; |

| Name: | GQ105J Printing Ink Purify High Speed Tubular Centrifuge Separator; | Dimension(L*W*H): | 800*700*1400; |

| Place of Origin: | Liaoning, China; | Motor: | Y90S-2 Explosion Proof; |

| Throughput: | 1200 kg/h; | Warranty: | 1 Year; |

| Weight: | 400; | Max Rotating Speed: | 16000 r/min; |

| Video outgoing-inspection: | Provided; | Bowl Diameter: | 105 mm; |

| Product Type: | oil cleaning centrifuge; | Voltage: | As Customer Requirement; |

| Working Volume: | 5.5L; | Power: | 2200; |

| Core Components: | PLC,Engine,Motor,Pressure vessel,bowl; | Showroom Location: | None; |

| Machinery Test Report: | Provided; | Separation Factor: | 15025; |

| Brand Name: | Zonelink; | Payment Terms: | L/C,T/T; |

| Package Preview: | ; | Port: | Dalian, China; |

| Bearing: | Import Bearing; | Material: | Stainless steel; |

| Packaging Detail: | wooden case (GQ105J Printing Ink Purify Tubular Centrifuge Separator); |

Product Description

Main Application

GQ type tubular centrifuge is mainly used for separating all kinds of suspension difficult to be separated, especially suitable for separation of solid-liquid suspension with light concentration,

heavy viscosity,fine particles and very small differential gravity of the two phases.For example clarifying all kinds of medicine fluid, glucose chlorhexidine, malic acid, oral solution, radix soghorae tonkinensis, coal tar and graphite; extracting protein, algae, saponin, pectin, sirup; blood separation, settling vaccine mycelia and all kinds of glucose; refining paint, resin, and latex solution.

Painted ink separation

Bacterial broth separation

Silicon powder separation

Structure & Principle

Tubular centrifuge separator is high speed centrifuge with strong capacity. The main parts: machine body, driving part,bowl,liquid collecting pan, liquid-in bearing seat.The material is sprayed onto the bowl from the inlet on the bottom and strong centrifuge force is formed when the bowl rotates with the material and that makes the material flow upper along the wall of the bowl and then separated because of the different gravity by the centrifuge force. GQ-for clarification: Heavy solid is deposited on the inner wall of the bowl,and forms the sludge. And it will be discharged by manual after the machine stops. The clear liquid flows out of outlet from the top of the bowl.The motor connect with the big pulley and delivery the power to the spindle through the belt, tensioner and small pulley and rotate with the bowl in high-speed as the clockwise. |

Detailed Images

Package & Shipping

Related Products

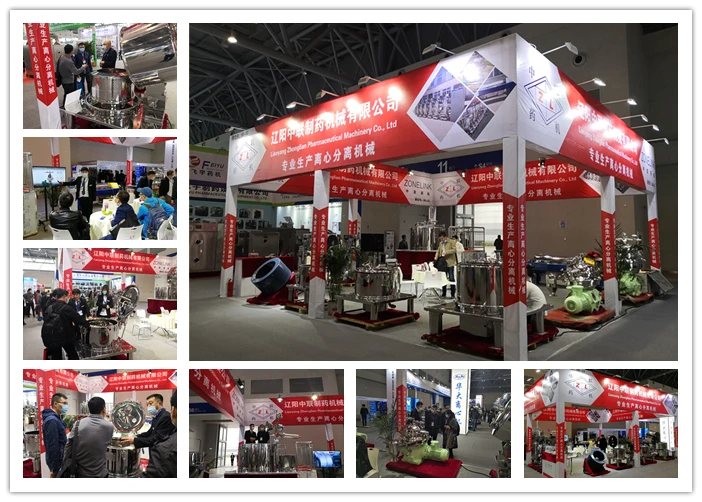

Company Information

VR

VR

Liaoyang Zhonglian Pharmaceutical Machinery Company was established in October 2001,own many years of professional production experience.The company is located in China's earliest engaged in the centrifuge factory liaoyang city,liaoning province,covers product workshop area of seven thousand square meters,special engaged in the centrifuge separator and other pharmaceutical machinery.The products have been widely used in many industries,such as pharmaceutical,food,chemical and many other industries.Our products were exported to many countries,North American countries such as the USA, Mexico.Aoutheast Asian countries such

as Thailand, Singapore, Malaysia, Indonesia.East Asian countries such as Korea.South American countries such as Venezuela, Peru. With reliable quality & excellent after-sales service,we won the support of the broad masses of overseas customers.

as Thailand, Singapore, Malaysia, Indonesia.East Asian countries such as Korea.South American countries such as Venezuela, Peru. With reliable quality & excellent after-sales service,we won the support of the broad masses of overseas customers.

VIEW MORE

You may like

-

PSB800 vertical centrifuge uses centrifugal force to clean waste oil, top feeding and unloading

-

Plastic Coconut Oil Pipe Separator Centrifuge Tube Stainless Steel Made in China

-

All stainless steel 450 filter vibrating screen/soy milk machine liquid vibration filter with cart

-

Liquid-solid separator DAF biogas dissolved air flotation for other water treatment equipment

-

Bread Brewer's Yeast Disc Centrifuge with Nozzle (Nozzle Centrifuge)

-

Hot aluminum ash separator to process 700 degrees Celsius aluminum ash

-

Innovative solid decanter centrifuge

-

Laboratory economical/low price disc centrifuge

-

Large Capacity High Quality Cannabis Extraction Centrifuge

-

2018 honey centrifuge extractor and bee centrifuge honey machine

Other Products

-

$7800.00 / set

$7800.00 / set -

$3400.00 / set

$3400.00 / set -

$2000.00 / unit

$2000.00 / unit

Related Search

centrifugal filter for olive oil

oil tubular centrifuge

dhc fish oil centrifuge separator

can you substitute butter for vegetable oil

awwa gate valve for water oil gas

510 best pen vape for hemp oil

laboratory centrifuge separator

centrifuge separator machine

centrifuge separator mini centrifuge

centrifuge machines for casting suppliers