TRINTFAR Automatic Vertical Stainless Steel Resistance Spot Welding Machine With Cheap Price Welder Spot Welders

-

Supplier: Shanghai Trintfar Intelligent Equipment Co., Ltd. -

Region: Shanghai, China -

Price: $1000.00 /set -

Min. Order: 1 set

Product details

| Product Name: | Medium Frequency spot welding machine; | Marketing Type: | Ordinary Product; |

| Core Components: | Pressure vessel; | Electrode Stroke: | 50-100mm; |

| Place of Origin: | Shanghai China; | After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; |

| Rated Capacity: | 50 Kva; | Showroom Location: | None; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Warranty of core components: | 3 years; |

| Key Selling Points: | Automatic; | Machinery Test Report: | Provided; |

| Electrode Pressure: | 1200N-18000N; | Local Service Location: | None; |

| Cooling Water: | 20-60L/min; | Video outgoing-inspection: | Provided; |

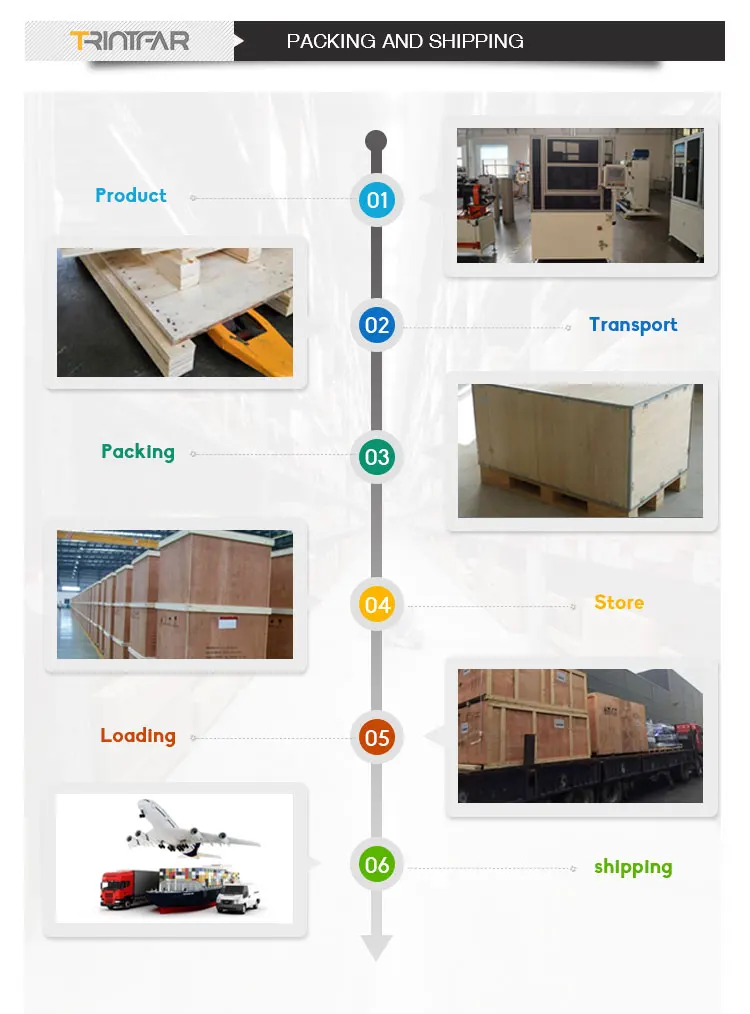

| Rated Duty Cycle: | 50%; | Single package size: | 100X100X100 cm; |

| Warranty: | 3 years; | Packaging Detail: | wooden box; |

| Selling Units: | Single item; | Condition: | New; |

| Single gross weight: | 300.0 KG; | Usage: | Spot Weling; |

| Applicable Industries: | Building Material Shops,Machinery Repair Shops,Manufacturing Plant,Home Use,Construction works ; | Weight (KG): | 300; |

| Package Preview: | ; | Brand Name: | TRINTFAR; |

| Maximum short current: | 10KA-120KA; | Rated duty cycle: | 50%; |

Product Description

Support the proofing of welding products.Customized service: We can design and develop welding machines according to your requirements. We have many welding design cases, including automatic welding production lines. We are an efficient and capable OEM supplier.

Feature:

* The power supply unit's duty are balanced. Three phase power make MD frequency inverter more adaptable in winding and pressure of wire.

* More preaser, faster current control, can analyse parameters more and faster compare with power frequency system.

* Faster to set up current, the speed is 20folds quicker than traditional technic

* Process more reliable: the majority of the application of solder DC welding metal effect will be even better.

* Reduce operating costs, including energy savings each and every point of welding as well as shortening the welding cycle.

* Save energy :especially suitable for welding thick workpieces and high-conductivity metal .such as aluminum and galvanized steel sheet.etc.

Specification

Model | Maximum Short Current KA | Rated Duty Cycle % | Secondary Voilage V | Rated Power KVA | Electrode Pressure N | Electrode Stroke mm | Cooling Water L\mim |

MD-10T | 10 | 50 | ≈9.8 | ≤20 | 1200 | 50 | 20 |

MD-20 | 20 | 50 | ≈9.8 | ≤50 | 4700 | 80 | 24 |

MD-25 | 25 | 50 | ≈9.8 | ≤70 | 4700 | 80 | 24 |

MD-40 | 40 | 50 | ≈11.6 | ≤120 | 7300 | 80 | 30 |

MD-60 | 60 | 50 | ≈11.6 | ≤160 | 12000/18000 | 100 | 50 |

MD-80 | 80 | 50 | ≈11.6 | ≤240 | 12000/18000 | 100 | 50 |

MD-120 | 120 | 50 | ≈11.6 | ≤300 | 18000 | 100 | 60 |

Company Profile

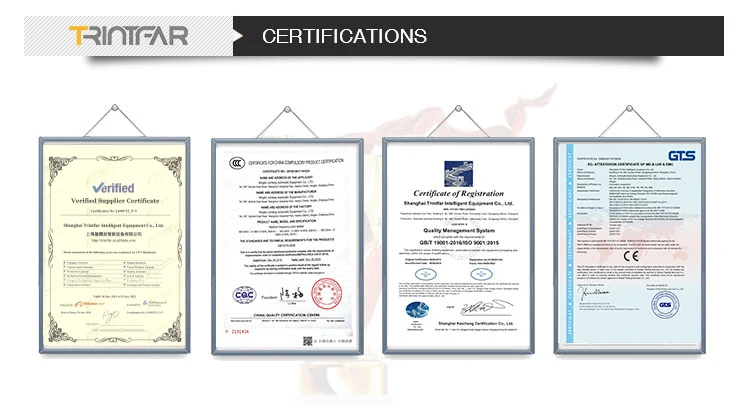

Established in 1995, Trintfar is a high-tech enterprise of automatic welding equipment integrating scientific research, development, manufacturing and sales.

As a national high-tech enterprise, after more than 20 years of unremitting efforts, Trintfar has many cutting-edge welding technology products, including medium frequency, high frequency inverter resistance welding machine, numerical control resistance welding, laser welding equipment, automobile welding production line, welding robot integrated system, high speed steel drum seam welding machine, etc. It is not only used in major automobile manufacturing and parts manufacturing enterprises, but also in aerospace, home appliance manufacturing, high-speed rail, low-voltage electrical appliances and other industries. The innovative team, excellent product design, advanced technology and reliable quality have made the Trintfar brand a reputation as a "reliable partner" in the welding equipment market at home and abroad.

At present, Trintfar has a large number of high-quality talents who are dedicated, innovative, and united. All staffs adhere to the "sincere, innovative" business philosophy, has been committed to providing customers with efficient welding automation solutions. From consulting to welding equipment operation and maintenance, our service has been accompanied by our customers.

With high-tech and high-quality services, we will continue to work hard and innovate. We sincerely and enthusiastically expect to share with our customers the high efficiency, high quality and work pleasure brought by our combination of advanced technology and lean production.

VIEW MORE

You may like

-

SW-2500 Capacitor Discharge Stud Welder Inverter Carbon Steel Stud Welder

-

China factory production hot sale wholesale hardware wire mesh factory dedicated 300KVA gantry multi-row welding machine multi-point welding machine

-

Automatic Resistance Roll Seam Welders for Chimney Welding, Stainless Steel and Carbon Chimney Welders

-

Stud Welder Capacitor Discharge Welder Carbon Steel Inverter Welder

-

Double Sided Spot Battery Welding Machine Automatic For Cylindrical Lithium Battery

-

Battery Welding Machine Resistant Welder 18650 21700 26650 32700 Battery Pack Welder

-

Ordinary self-fur welded mesh machine

-

AC high-efficiency intermediate frequency inverter DC spot welding machine/pedal resistance spot welding machine

-

Steel bar welding machine net width 2500mm diameter 6mm to 12mm

-

WIP-70A-05YC/WIT-70A(YPB-200) Customized Inverter DC Resistance Welding Power Source Portable Spot Welding Machine

Related Search

stainless steel water tank welding machinery

stainless steel flour dough mixer machine price

stainless steel china frozen yogurt machine

electric resistance seam welding machine

steel wire mesh welding machines

stainless steel meat slicer grinder machine

stainless steel uht wine sterilization machine

stainless steel spinach vegetable cutting machine

brc steel wire mesh welding machine

hydraulic stainless steel square tube punching machine