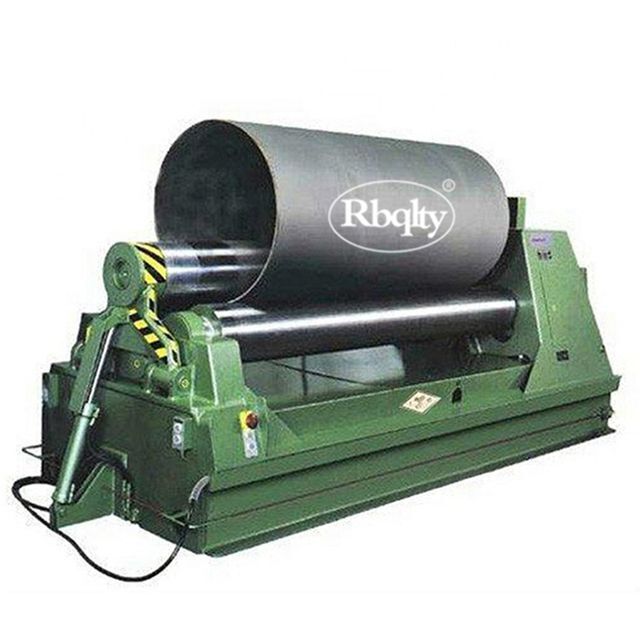

CNC iron sheet bender metal sheet rolling machine 3 roller steel plate bending machine

-

Supplier: Anhui Runbang Heavy Industry Machinery Co., Ltd. -

Region: Anhui, China -

Contact: Ms Sammi Wang -

Price: $5500.00 / 1 - 4 sets

$3200.00 / >=5 sets -

Min. Order: 1 set

| Voltage: | 220V/380V/400V; | Name: | 3 roller bending machine; |

| Keyword: | metal sheet rolling machine; | Applicable Industries: | Building Material Shops,Manufacturing Plant,Machinery Repair Shops,Advertising Company; |

| Max. Working Length (mm): | 2500; | Rolling Speed (m/min): | 1 - 4; |

| Warranty of core components: | 24 months; | Weight (KG): | 10000; |

| Application: | Construction Projects; | Place of Origin: | Anhui China; |

| Material / Metal Processed: | Aluminum; | Package Preview: | ; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; |

| Packaging Detail: | normal are plastic film; | Brand Name: | rbqlty; |

| Payment Terms: | L/C,Western Union,T/T,MoneyGram; | Automation: | Automatic; |

| Model: | 3 roller steel plate bending machine; | Material: | Q235; |

| Local Service Location: | Malaysia,Sri Lanka,India,Mexico,Thailand; | No. of Roller: | 3; |

| Color: | Customized; | Video outgoing-inspection: | Provided; |

| Machine Type: | Roller-Bending Machine; | Motor Power (kw): | 11; |

| Certification: | ce; | Supply Ability: | 5 Set/Sets per Month 3 roller bending machine; |

| Max. Plate Thickness (mm): | 12; | Type: | Hydraulic Bending Tools; |

| Usage: | Metal Sheet Rolling Cutting Bending; | Port: | Shanghai/Wuhu/Tianjin/Shanghai; |

| Condition: | New; | Key Selling Points: | High Safety Level; |

| Core Components: | PLC,Engine,Bearing,Gearbox,Motor,Pressure vessel,Gear,Pump; | Showroom Location: | Sri Lanka,Malaysia,India,Mexico,Thailand; |

| Machinery Test Report: | Provided; | Marketing Type: | New Product 2020; |

| Warranty: | 12 Months,1 Year; |

The Features

1, High Precision end Pre-bending

The straight enge length can be set freely, the upper roller press to pre-bend NC Control, high productivity.Parameters are controlled by NC, easy for operation, improve the productivity greatly

2, Good accuracy

The upper roller is like a drum, the lower rollers assorted with it through support rollers. Bend continuously, can roll ideal products from thin to thick plates widely

3, Safety

The lower rollers are fixed, the upper roller move vertically and horizontally. The job does not work with the working rollers. Complete structure, simple foundation, convenient movement. The machines has unitary basement, does not need earth bolts, has simple foundation

Main parts:

1.Working rollers: cast steel ingot(chemical composition analysis):check performance-forging roughcast-forging annealing-UT flaw-roughing(chemical tests)-heat treatment(hardening and tempering)-UT flaw-semi finishing-finishing-MT.

2..Large forigings: cylinder body, gear, gear shaft forging roughcast-surface imspection-roughing-UT flaw-UT flwa detector hear treatmenat-finishing semi-finishing-MT.

3.Welding structure: racks, chassis, wheel box plate into the factory(chemical compositon analysis, mechanical test)-pretreatment-for sheet metal cutting-welding-seam UT or RT flaw-annealing treatment-roughing-finishing-vibration destressing-hot blasting-finishing 5-4 major parts of the manufacturing process.

The Technical Parameters

Optional Special Device

Payment terms | T/T | FOB | 30% T/T in advance, paid the balance before shipment | ||

C&F(CRF) | 30% T/T in advance, paid the balance against copy of B/L | ||||

CIF | |||||

L/C | L/C at sight or L/C 30 days is also accepted | ||||

D/P | D/P is available for long-term cooperated customer | ||||

Lead time | Normally 7-15 days after deposit or L/C received | ||||

We welcome use Trade Assurance, you'll enjoy:

100% product quality protection

100% on-time shipment protection

100% payment protection for your covered amount

The normal package is waterproof plastic film, or can be also according to the requirement of customer.

Runbang Heavy Machine Co.,Ltd

We make sheet metal processing machine like bending machine, shearing machine, iron worker, hydraulic press, punching machine, duct manufacturing auto line, cutting machine and so on

Expert Team

With an expert team in R&D for more than 20 years, occupied the work shop of over 30,000 square meters, Runbang is able to support you with best quality machines.

Warranty

- 1 year for main parts except accessaries.

- Do not cover wrong operation, careless maintenance, deliberate damage

1.Are you factory or trading company?

We are factory but also do trading.

2.How to operate your machine after bought from you?

We have detailed installation and operation manual.

Telephone and online support available.

3.What are your payment terms?

We support T/T, L/C, Western Union and so on.

Trade Assurance payment method is welcome.

-

Metal Sheet Slide Roller 4 Roller Portable Roll Forming Machine

-

Small and simple external probe type three-roll plate bending machine

-

AH Roll Bending Machines for (Power, NC Hydraulic, Hydraulic, Manual)

-

Three Roller Stainless Steel Rolling Machine

-

Doctson W11 automatic sheet metal rolling machine three-roll bending machine semi-automatic / small plate rolling machine customization

-

Professional manufacturer of W11S 12*2000 mechanical plate rolling machine, the price is negotiable

-

CNC Four Roller Bending Machine Double Pinch Stainless Steel Pipe Rolling Machine

-

W12-6X2000 Four-roll hydraulic plate bending machine

-

Used Aluminum Profile Sheet Metal Stainless Steel Plate Bending Three Roll Rolling Machine Price For Sale

-

Foil roller hydraulic machine Double bending machine

Other Products

-

$3880.00 / set

$3880.00 / set -

$2500.00 - $3400.00 / set

$2500.00 - $3400.00 / set -

$250.00 - $265.00 / set

$250.00 - $265.00 / set -

$500.00 - $800.00 / set

$500.00 - $800.00 / set -

$4000.00 - $7900.00 / set

$4000.00 - $7900.00 / set -

$5000.00 / set

$5000.00 / set -

$24592.00 / set

$24592.00 / set -

$32835.00 / set

$32835.00 / set -

$4692.00 / set

$4692.00 / set -

$4500.00 / set

$4500.00 / set