Delem DA66T DA58T DA52S 3+1 axis cnc hydraulic press brake machine for stainless steel bending folding

-

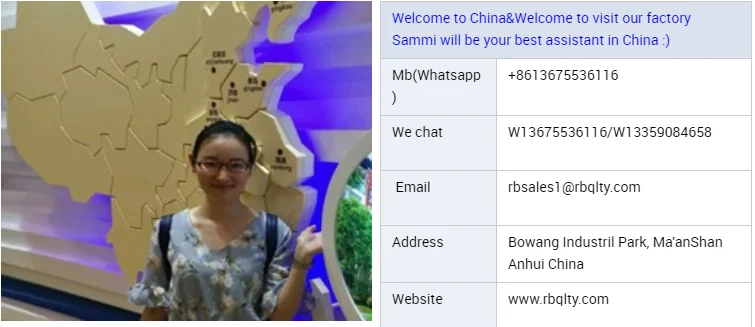

Supplier: Anhui Runbang Heavy Industry Machinery Co., Ltd. -

Region: Anhui, China -

Contact: Ms Sammi Wang -

Price: $24592.00 /set -

Min. Order: 1 set

| Certification: | CE; | Warranty: | 3 years; |

| Mode: | CNC automatic; | Single gross weight: | 7.5 KG; |

| Key Selling Points: | Automatic; | Brand Name: | rbqlty; |

| Package Preview: | https://sc02.alicdn.com/kf/HTB1SgZtaA5E3KVjSZFC762uzXXaE.png_640x640.png; | Application: | steel sheet plate/stainless steel /aluminium/copper; |

| Motor: | Germany Siemens Brand; | Selling Units: | Single item; |

| Keyword: | CNC bending machine; | Machine Type: | cnc Press Brake; |

| Machine Type: | Torsion Bar; | Length of Working Table (mm): | 2500; |

| Control system: | DA-52, DA41, E300,E200; | Automatic Level: | Fully Automatic; |

| Hydraulic system: | Germany Bosch-Rexroth; | Automation: | Automatic; |

| After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support,Online support; | Raw Material: | Hard steel Q235A; |

| Color: | Customized; | Year: | 2019; |

| Nominal Pressure (kN): | 1250; | Weight (KG): | 1650; |

| Extra Services: | End Forming; | Single package size: | 40X20X15 cm; |

| Material / Metal Processed: | Brass / Copper,Stainless Steel,ALLOY,Carbon Steel,Aluminum; | Condition: | New; |

| Motor Power (kw): | 3; | Package Type: | Delem DA66T DA58T DA52S 3+1 axis cnc hydraulic press brake machine for stainless steel bending folding; |

| Electric: | France Schneider; | Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Machinery Repair Shops,Manufacturing Plant,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company; |

| Place of Origin: | Anhui China (Mainland); |

Delem DA66T DA58T DA52S 3+1 axis cnc hydraulic press brake machine for stainless steel bending folding

Bending metal machine Main features:

1,Structure:

1)Complete steel-welded structure;

2)ANSYS finite element analysis software to ensure the reliability of the machine and the precision;

2, Main oil cylinders:

1)Closed loop control mode:Germany electro-hydraulic servo valve and imported grating ruler;

2)Totally different from traditional mechanical stop bending machines;

3)High precision of the glide position and bending;

4)Accurate and stable operation.

3,Back gauge:

1)Imported functional components to ensure the stopping precision.

2)More functional multi-axis blocking is available according to customer's requirement.

4,Hydraulic system:

1)Integrated control system imported from Germany;

2)Decrease the installation of pipelines;

3)Ensure the working stability and better appearance.

5,Body sides:

1)C shaped plates are fitted on both sides;

2)The high precision grating ruler is on the C shaped plates;

3)Avoid the influences on bending precision arising from distortion of machine body during bending process.

6, Compensation mechanism:

1)Hydraulic automatic deflection compensation mechanism;

2)Ensure effective compensation without blind area;

3)High precision of bending and long stability.

Bending metal machine technical data:

Name: Electronic system

Brand: Schneider

Original: Germany

Good quality to make sure the safety and efficiency

Name: hydraulic Valve

Brand: BOSCH REXROTH

Original: German

safe and efficient with good quality

Name: Fast mold clamp (can be optional)

Brand: rbqlty

Original: China

To make it fast and easy to take up and down the metal plate

Name: hydraulic valve

Brand: BOSCH REXROTH

Original: German

safe and efficient with good quality

Grating ruler:To avoid the influences on bending precision arising from distortion of machine body during bending process.

Durable and reliable

Back gauge:to make the bending precision much better by this. Sheet metal positioning function, to control well the processing metal plate position .

Very important part in bending machine.Tai wan HIWIM Ball screw and linear guide

Electric table crowning

Machine Parts--Control System

Name: DA-52

Brand:Delem

Original: Holland

Servo control technology;

4.7" bright LCD display,multi-langyage

Store 100 programs, each including 25 steps

power off memory function

We welcome use Trade Assurance, you'll enjoy:

100% product quality protection

100% on-time shipment protection

100% payment protection for your covered amount

Fiber laser cutting machine

IPG/RAYCUS/MAX

Hydraulic shearing machine

E21S/DA360

Power press machine

Mechanical/pneumatic/hydraulic

Anhui Runbang Heavy Industry--Rbqlty

Anhui Runbang Heavy Industry Machinery Co.,Ltd concentrates on the research, development, manufacture, sale and service in metal fabrication equipment.

We have an educated, young and professional technician team devoting themselves to the research and development of metal sheet shearing, bending,

punching, rolling machine tool. We can provide you the most reasonable and complete metal fabrication solution.

Rbqlty is our registered brand name. it represents Runbang and Quality. Runbang is a quickly develping company putting quality as first priority and final goal . We strive to supply you best quality machine tool by our scientific management , advanced technology , novel design, reasonable price and perfect service.

Sincerely looking forward to develop with you together!

Pre-Sales Service

* Inquiry and consulting support.

* Reply within 1 hour. Offer with machine details will send out within one working day.

* Sample testing support.

* View our Factory.

* OEM & ODM support

On-sales Service

* Production situation report.

* Vessel booking service.

* Documents support.

* Machine checking support

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

* 24 hours hotline .Online installation and operation instruction.

* Life long machines Consultant

Any interested in , pls contact Crystal for Enquiry - Sincerly !

-

Manual or pneumatic table stainless steel sheet metal / sheet metal bending machine / plate bending machine

-

DAMA TP10 Hydraulic Press Brake Large Heavy Duty CNC Controller Hot Selling Press Brake

-

CAC-75W hydraulic angle steel bending machine

-

AH Press Brakes for (Manual, Hydraulic, NC Hydraulic, Manual Folding Machine, Power)

-

2022 European high standard low cost MB8 series 200Tons/3200 CNC bending machine for sale

-

3KW Plate Bending Machine Hydraulic Multifunctional Steel Plate Bending Machine

-

Manual Sheet Bending Machine Hydraulic Bending Machine Metal Bending Machine

-

(W1.0X610B, W1.0X915B, W1.5X1220Z ) small handbrake/disc & box brake with CE, best price

-

Tool molds on bending machines, press blades on bending machines

-

Hot selling hydraulic new bending machine sheet metal bending machine 80t 3000 4000 6000

Other Products

-

$3880.00 / set

$3880.00 / set -

$2500.00 - $3400.00 / set

$2500.00 - $3400.00 / set -

$250.00 - $265.00 / set

$250.00 - $265.00 / set -

$500.00 - $800.00 / set

$500.00 - $800.00 / set -

$4000.00 - $7900.00 / set

$4000.00 - $7900.00 / set -

$3200.00 - $5500.00 / set

$3200.00 - $5500.00 / set -

$5000.00 / set

$5000.00 / set -

$32835.00 / set

$32835.00 / set -

$4692.00 / set

$4692.00 / set -

$4500.00 / set

$4500.00 / set