CIL Plant

-

Supplier: Jiangxi Well-Tech International Mining Equipment Co., Ltd. -

Region: Jiangxi, China -

Contact: Ms Mily Huang -

Price: $10000.00 /set -

Min. Order: 1 set

| After-sales Service Provided: | Engineers available to service machinery overseas; | Capacity: | 1t/h-10t/h; |

| Local Service Location: | Egypt,Canada,Mexico,Malaysia,Australia,Morocco,Colombia; | Port: | China Xiamen; |

| visit factory: | welcome; | Warranty: | 1 Year; |

| Payment Terms: | L/C,T/T; | Showroom Location: | Egypt,Canada,Morocco; |

| Production Capacity: | 80%; | Motor Type: | AC Motor; |

| Certification: | ISO9001:2008,SGS; | Place of Origin: | Jiangxi China; |

| spare parts: | supply; | whole line machine: | supply; |

| Dimension(L*W*H): | Diffirent Model; | Brand Name: | Gandong; |

| Condition: | New; | Applicable Industries: | Energy & Mining; |

| Application: | Mineral Leaching Process; | Type: | Leaching Tank; |

| Supply Ability: | 10 Set/Sets per Month; |

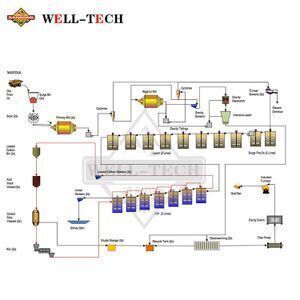

Process Introduction

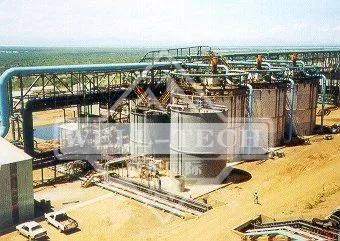

Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%. It has become the first choice of modern gold mining and beneficiation plant design.

Application

CIL mainly applies for the process of above 1g/t grade gold ore and gold ore with large bearing ore volume: silver, platinum, copper, etc. As CIL sees a better performance in extracting these minerals at the same time. And our Mineral Dressing Test Center can help you with the component testing of your ores.

Flow Design Equipment

n After Crushing and Comminution, add the gold ore slurry into 9 Leaching Agitation Tanks, pour in cyanide solution in the first 2 tanks and Activated Carbon in the following 7 tanks for the reverse-absorption process--This design shortens the time period of gold staying in the cyanide pregnant solution and recovers gold in advance, which sees a faster investment return compared to other designs.

n Filter Press and Vibrating Screen is needed in gold ore slurry reverse-transmission process.

n We have a design that ensures the minimum carbon gold loses during transmission. It lower the gold loses and the processing line is easy to maintain.

n After the carbon leaching and Elution of gold, NaCN and NaOH solution is used for removing the gold from loaded carbon at a high temperature. Then the loaded solution passes through the electro winning cell and the metals are attached to cathodes.

Our Desorption Electrolysis System can successfully aggregate these steps in one processing unit, the pure gold and other useful metals are highly attained via this system.

Rock gold plant use gravity seoarator way

Rock gold plant use gravity seoarator way

if you are interested in our products, please send us message in below blank, then click“send”, we will reply within 24hours,or call us. thanks your time.

Mobile/WhatsApp:+86 183 7987 3189 Mily

-

Gold Mining Leaching Tank/CIL Small Gold Processing Plant Mixing Tank

-

Mineral mud mixing tank Mixing tank Mineral mixing barrel

-

Mixing tank high-efficiency high-quality mixing tank / mineral mixer / mixing bucket

-

XB-1000 gold stirring leaching tank

-

Mixed leaching tank / gold ore stirring leaching tank

-

High-efficiency beneficiation mixing mixing tank gold ore tailings leaching processing plant mixing mixing tank with agitator

-

High quality mining equipment double impeller leaching mixing tank for gold mine

-

Energy-saving gold stirring leaching tank

-

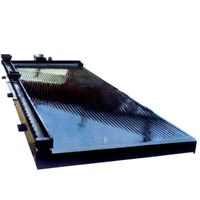

High quality vibrating table top of 6S vibrating table for gold ore separation

-

High-quality mining barreled equipment gold leaching mixing tank