Extraction CBD Oil Centrifuge Liquid Centrifugal Extractor

-

Supplier: Henan Lanphan Industry Co., Ltd. -

Region: Henan, China -

Contact: Ms Jingli Liu -

Price: $6823.00 /unit -

Min. Order: 1 unit

| Weight: | 260kg; | Core Components: | PLC,Engine,Bearing,Gearbox,Motor; |

| Name: | trimmer dry hemp; | Local Service Location: | United States; |

| Selling Units: | Single item; | Drum diameter(mm): | 800-1600; |

| Showroom Location: | United States; | Applicable Industries: | Manufacturing Plant,Machinery Repair Shops,Energy & Mining; |

| Separation factor: | 650; | Packaging Detail: | Packing: carton or wooden case package, customized package is available.; |

| Warranty of core components: | 1 Year; | Video outgoing-inspection: | Provided; |

| Marketing Type: | Hot Product 2019; | Voltage: | 220V/60H; |

| After Warranty Service: | Video technical support,Online support; | Motor power(Kw): | 7.5-37; |

| Feature: | hemp extraction system; | Single package size: | 70X60X60 cm; |

| Product Type: | FERTILIZER; | Type: | Extraction Equipment; |

| After-sales Service Provided: | Video technical support,Online support; | Certification: | CE; |

| Key Selling Points: | Long Service Life; | Package Preview: | ; |

| Drunm speed: | 1200 r/min; | Warranty: | 1 Year; |

| Machinery Test Report: | Provided; | Condition: | New; |

| Place of Origin: | Henan China; | Single gross weight: | 59.0 KG; |

| Power: | 1.5kw; | Dimension(L*W*H): | 110*65*102 cm; |

| Brand Name: | Lanphan; |

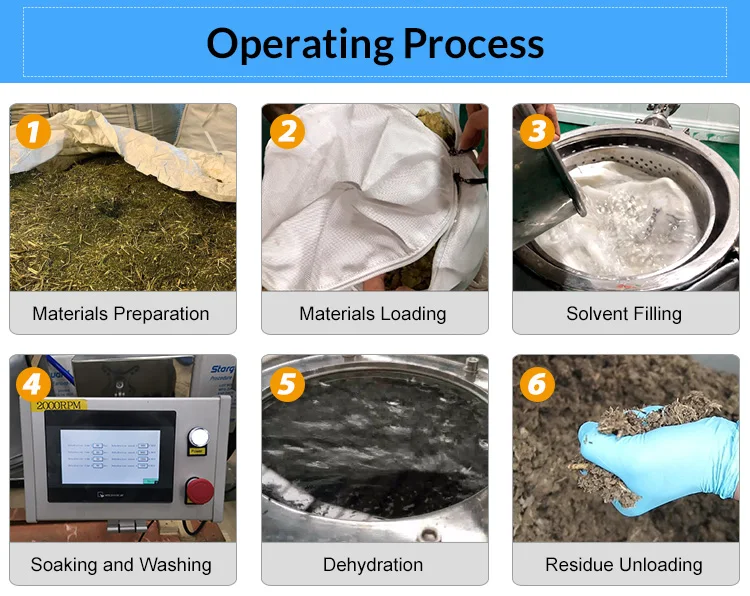

Working principles of centrifuge extractor

Lanphan PP centrifuge is to use centrifugal force to accelerate the liquid phase in the solid-liquid mixed

liquid out of the rotating drum, and leave the solid phase in the rotating drum, so that the different materials that need to be separated can be accelerated to separate the machine.The operator should fill the filter bag with crushed plant material and places it in the machine. Then, add alcohol until the plant material is submerged. After soaking at low temperature and setting a program to rotate at a low speed in both directions,the active ingredients in the plant are fully extracted. Rotate at high speed and open the bottom discharge valve to discharge the extract.

|

Model

|

Drum

|

Storage capacity (L) | Interlayer capacity (L) | Motor Power (KW) | Power voltage | ||||

| Hemp powder (LB/batch) | Capacity (L) | Diameter (mm) | Height (mm) | Rotary speed (rpm) | |||||

| PP-15 | 6.5 | 15 | 300 | 250 | 2000 | 30 | 9 | 1.1 |

220V/60Hz

Single phase / three phase

|

| PP-25 | 11 | 25 | 300 | 350 | 2000 | 40 | 12 | 1.5 | |

| PP-45 | 20 | 45 | 450 | 300 | 1500 | 85 | 20 | 2.2 | |

| PP-60 |

28

|

60 | 450 | 400 | 1500 | 106 | 25 | 3 | |

| PP-110 | 50 | 110 | 600 | 400 | 1250 | 175 | 33 | 4 | 220V/60Hz Three phase |

| PP-140 | 65 | 140 | 600 | 500 | 1250 | 210 | 40 | 5.5 | |

| PP-250 | 117 | 250 |

800

|

500 | 1100 | 380 | 55 | 11 | |

| PP-480 | 225 | 480 | 1000 | 600 | 1000 | 748 | 90 | 15 | |

| PP-860 | 413 | 860 | 1250 | 700 | 950 |

1250

|

130 | 18.5 | |

Remarks:

Can be soaked, with interlayer and insulation

PP centrifuge is an independent research and development product of our company. All the mechanical processing is completed in the factory. According to the different needs of customers, we design and process it by ourselves.

1. The material contact parts (including the main shaft and the bottom of the drum) are made of SUS304 or SUS316L, and the surface is treated with sanitary grade without dead angle.

2. Applicable temperature range: -50℃ to 50℃.

3. The structure of the large sight glass to clearly see the situation in the equipment.

4. Fully automatic extraction process, and simple control panel. The program can set the drum forward and reverse, speed, time and cycle times, and can switch manual control. Temperature, spin speed and time can also be set independently.

5. The filter bag adopts zipper type to prevent material leakage, and is designed for single-person operation and can be quickly loaded and unloaded.

-

PSB800 vertical centrifuge uses centrifugal force to clean waste oil, top feeding and unloading

-

Plastic Coconut Oil Pipe Separator Centrifuge Tube Stainless Steel Made in China

-

All stainless steel 450 filter vibrating screen/soy milk machine liquid vibration filter with cart

-

Liquid-solid separator DAF biogas dissolved air flotation for other water treatment equipment

-

Bread Brewer's Yeast Disc Centrifuge with Nozzle (Nozzle Centrifuge)

-

Hot aluminum ash separator to process 700 degrees Celsius aluminum ash

-

Innovative solid decanter centrifuge

-

Laboratory economical/low price disc centrifuge

-

Large Capacity High Quality Cannabis Extraction Centrifuge

-

2018 honey centrifuge extractor and bee centrifuge honey machine

Other Products

-

$1450.00 - $2450.00 / unit

$1450.00 - $2450.00 / unit -

$699.00 - $708.00 / unit

$699.00 - $708.00 / unit -

$6399.00 - $6799.00 / unit

$6399.00 - $6799.00 / unit -

$1269.00 / set

$1269.00 / set -

$850.00 / unit

$850.00 / unit -

$8800.00 / unit

$8800.00 / unit -

$62.00 / set

$62.00 / set -

$550.00 / unit

$550.00 / unit -

$523.00 / unit

$523.00 / unit