MF ceramic membrane filter pilot plant for wine clarification

-

Supplier: ZIBO DONGQIANG MEMBRANE TECHNOLOGY CO.,LTD. -

Region: Shandong, China -

Contact: Mr yuanqiang zhao -

Price: $2000.00 /piece -

Min. Order: 1 piece

| Certification: | CE; | Model Number: | DQCMF; |

| Place of Origin: | Shandong China (Mainland); | Type: | crossflow filtration; |

| Processing: | Filter; | Port: | Qingdao; |

| pore size: | 20,30,50,100,200,500,800,1200nm; | Condition: | New; |

| Supply Ability: | 5 Piece/Pieces per Month; | Payment Terms: | L/C,T/T,Western Union; |

| Packaging Detail: | wooden carton; | Delivery Detail: | 25 days; |

| Brand Name: | DQ; | application: | wine,beverage clarification and purification; |

MF ceramic membrane filter pilot plant for wine clarification

1:System Components:

Membrane module(membrane,ss housing),feed tank,centrifugal pump,flow/pressure /temperature meter,electric control panel,valves and pipes;

Type of module(number of membranes/housing) : 1,3,7,12,19,37,61,91 pcs

Length of membrane: 250-1200mm

Outer diameter of membrane: 12/25/30/40/52/60mm

Material of body: SS304,SS316L,Titanium,FRPP,MSRL;

Material of seals: EPDM;Fluoro Rubber;Silicon;

2: Filtration mode: cross flow filtration;

3: Properties:

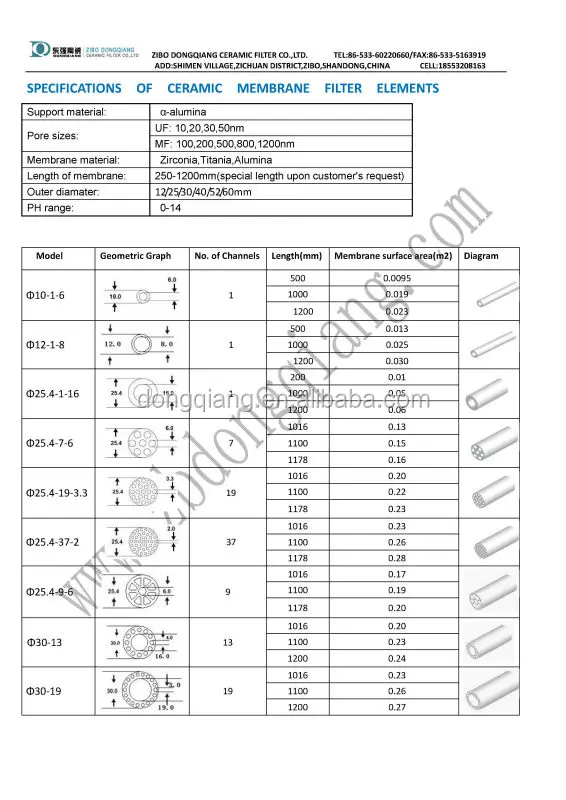

Support material: | α-alumina |

|

|

Pore sizes: | UF: 10,20,30,50nm |

| |

MF: 100,200,500,800,1200nm |

| ||

Membrane material: | Zirconia,Titania,Alumina |

| |

Length of membrane: | 250-1200mm(special length upon customer's request) | ||

Outer diamater: | 12/25/30/40/52/60mm |

|

|

Working pressure: | ≤1.0MPa |

|

|

Burst pressure: | ≥9.0MPa |

|

|

Working temperature: | -5-120℃ |

|

|

PH range: | 0-14 |

|

|

4:

5:

Ceramic Membrane Comparison with traditional filtration system

Compared with such tradition filter like Filter Press, Centrifuge, DE Filter and organic membrane, Ceramic Membrane has many unique advantages.

1. Excellence resistance to acid, alkaline and oxidation chemicals.

2. Solvent stability, high thermal stability.

3. Fine reparability with narrow pore size distribution.

4. Extremely long work life compared with polymeric membrane.

5: Easy to be cleaned and sanitized with back flush.

6:Applications:

Separation of liquids and solids;separation of oil and water;separation of liquids and liquids;

(especially for filtration of food and beverage industries,chemcical and petrochemical industries,

pharmaceutical and mining industries.)

Typical Applications:

1) Biochemical and Pharmaceutical Industries: Clarification and purification of the fermentation products as well as purification or separation of product slurries;

2) Environmental applications: Waste Water clarification and separation;

3) Food and Beverage Industry: Microfiltration of milk, clarification of fruit juice and separation of soyabean protein;

4) Highly useful for various filtration applications in the Petro-Chemical Industry;

5) Other fields: Reclamation of nano powders, filtration of acid/alkali containing liquids.

-

1 ton honey preheating mixed filtering concentrated honey processing machine

-

High Flow Diatomite Beer Filter / Candle Filter / Disc Filter for Beer Filtration

-

Lens module filter housings for breweries

-

High Flow Distillation Alcohol Filter Stainless Steel Cartridge Filter Housing for Wine Filtration Equipment

-

SiC silicon carbide ceramic membrane ultrafiltration and microfiltration for cutting fluid recovery

-

Using Grape Wine Membrane Filter Steel Training Stainless Steel HEN Power Food Technology Parts Pcs Mini Quantity Simple Best Price Home

-

Automatic diatomite beer filter, filter wine machine, stainless steel industrial filter equipment

-

High Efficiency High Quality PP Enol Filter Cartridges for Wine/Wine/Beverage Processing

-

WINE FILTER PLATE

-

wine filter

Other Products

-

$140.00 / piece

$140.00 / piece -

$200.00 / piece

$200.00 / piece -

$100.00 / piece

$100.00 / piece -

$10000.00 / piece

$10000.00 / piece -

$5000.00 / piece

$5000.00 / piece -

$100.00 / piece

$100.00 / piece -

$10000.00 / piece

$10000.00 / piece -

$1000.00 / set

$1000.00 / set -

$1000.00 / piece

$1000.00 / piece -

$10000.00 / piece

$10000.00 / piece