ceramic microfiltration membrane system for dairy process

-

Supplier: ZIBO DONGQIANG MEMBRANE TECHNOLOGY CO.,LTD. -

Region: Shandong, China -

Contact: Mr yuanqiang zhao -

Price: $100.00 /piece -

Min. Order: 1 piece

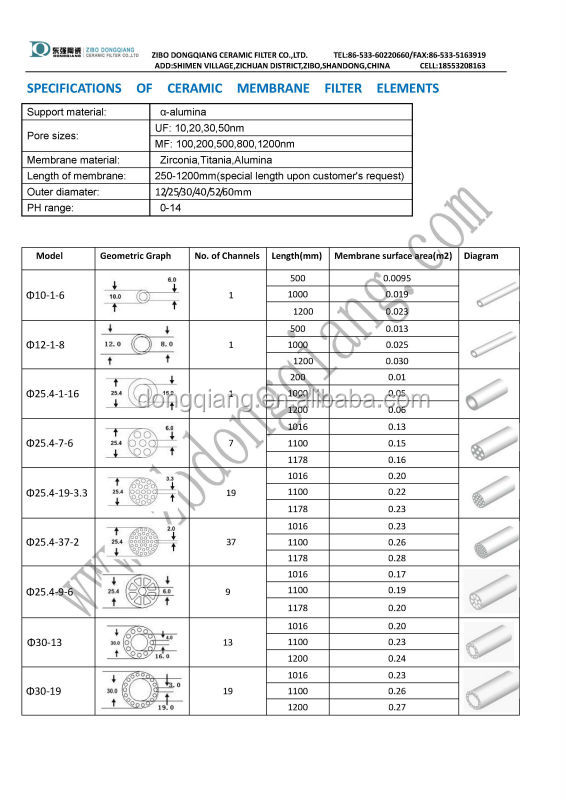

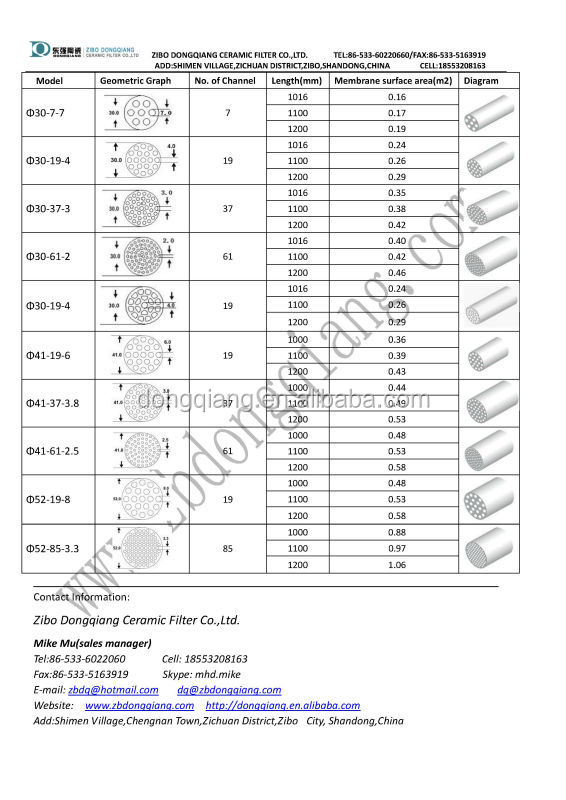

| model: | DQCMF | payment terms: | L/C, T/T, Western Union, PayPal |

| Supply capacity: | 3000 pieces per month | brand: | DQ |

| place of origin; place of origin: | Shandong China | Packaging Details: | wooden box |

| length: | 100-1200mm | Delivery Details: | 7-25 days, if in stock, ship immediately. |

| port: | Qingdao | Pore Size: | 20,30,50,100,200,500,800,1200nm |

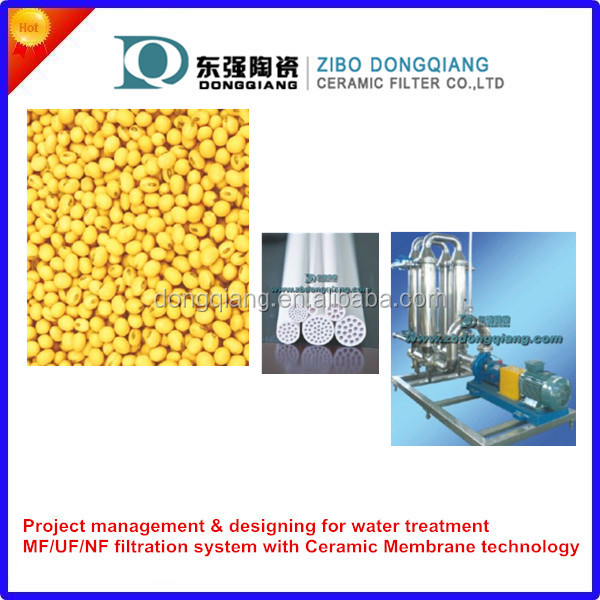

Microfiltration Ceramic Membrane System for Milk Processing

1:

2:

Comparison of Ceramic Membranes with Traditional Filtration Systems

Ceramic membranes offer many unique advantages over traditional filters such as filter presses, centrifuges, DE filters, and organic membranes.

1. Excellent resistance to acid, alkali and oxidizing chemicals.

2. Good solvent stability and high thermal stability.

3. Narrow pore size distribution and good repairability.

4. Compared with the polymer membrane, the service life is extremely long.

5: Easy to clean and disinfect, backwash.

3: Application:

Separation of liquid and solid; separation of oil and water; separation of liquid and liquid;

(especially suitable for filtration in the food and beverage industry, chemical and petrochemical industries,

Pharmaceutical and mining industries. )

typical application:

1) Biochemical and pharmaceutical industries: clarification and purification of fermentation products and purification or separation of product slurries;

2) Environmental application: wastewater clarification and separation;

3) Food and beverage industry: microfiltration of milk, clarification of fruit juice, wine and separation of soy protein;

4) Very useful for various filtration applications in the petrochemical industry;

5) Other fields: recovery of nano-powder, filtration of acid-base liquid.

*For more details, please contact us.

-

Microfiltration and Ultrafiltration Ceramic Membrane Filters for Separation of Solids from Liquids

-

MF, UF Ceramic Membrane Filters for Casein Concentration

-

Cathay Pacific 4040/8040 reverse osmosis seawater desalination water purification system RO membrane for drinking water plant

-

10,5,1 micron filter 10 inch PP Melt Filter Cartridge Machine PP Spun Cartridge Filter for Coatings

-

microporous polypropylene film / PP membrane

-

Professional hydrophobic pvdf membrane filter

-

ptfe membrane sheet for Science study

-

Professional hydrophobic pvdf membrane for pharmaceuticals / biological

-

beer yeast clarification with ceramic membrane microfiltration technology

-

PP / PES / Nylon micropore membrane filter

Other Products

-

$140.00 / piece

$140.00 / piece -

$200.00 / piece

$200.00 / piece -

$100.00 / piece

$100.00 / piece -

$10000.00 / piece

$10000.00 / piece -

$5000.00 / piece

$5000.00 / piece -

$10000.00 / piece

$10000.00 / piece -

$1000.00 / set

$1000.00 / set -

$1000.00 / piece

$1000.00 / piece -

$10000.00 / piece

$10000.00 / piece -

$3000.00 / piece

$3000.00 / piece