Drywall metal stud and track roll forming machine

-

Supplier: Cangzhou Zhongheng Machine Manufacture Co., Ltd. -

Region: Hebei, China -

Contact: Ms Shirly Zhang -

Price: $1400.00 / >=5 sets -

Min. Order: 5 sets

| Upper speed: | 20m; | Work Pressure: | 350MP; |

| Main motor: | 4kw; | After-sales Service Provided: | Online support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support; |

| Structure: | 400H beam; | Power: | 5.5+3KW; |

| Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Machinery Repair Shops,Manufacturing Plant,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company; | Local Service Location: | Egypt,Canada,United Kingdom,United States,Philippines,Brazil,Peru,Pakistan,Australia,Kenya,South Korea,Chile,Kazakhstan,Ukraine; |

| Machinery Test Report: | Provided; | Video outgoing-inspection: | Provided; |

| Key Selling Points: | Long Service Life; | Core Components: | PLC,Engine,Bearing,Gearbox,Motor,Pressure vessel,Gear,Pump; |

| Certification: | CE; | Showroom Location: | Egypt,United Kingdom,United States,Germany,Philippines,Brazil,Peru,Pakistan,Kenya,Chile,Kazakhstan,Ukraine,Kyrgyzstan,Uzbekistan,none; |

| Dimension(L*W*H): | 4700*850*1350; | Control system: | PLC(Delta brand); |

| Type: | Drywall metal stud and track U channel roll forming making machine,Steel Frame & Purlin Machine; | Production Capacity: | 50M/min; |

| Weight: | 2800KG; | Shaft material: | 45# Steel Outer Diameter: 75mm; |

| Warranty of core components: | 2 years; | Packaging Detail: | 1.Drywall metal stud and track roll forming machine need one 20/40 feet container to load . 2.We have professional technicians for loading to make sure machine has no damage. 3.Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you.; |

| Place of Origin: | Hebei China; | Cutting blade material: | Cr 12 High Grade Steel; |

| Brand Name: | ZH; | Single gross weight: | 2500.0 KG; |

| Single package size: | 450X85X135 cm; | Condition: | New; |

| Selling Units: | Single item; | Forming Stations: | 14; |

| Roller material: | CR12; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Voltage: | 380V OR custom; | Warranty: | 1 Year; |

| Marketing Type: | New Product 2020; |

| 1. Description of Drywall metal stud and track roll forming machine |

(1). Brief Introduction

The Drywall metal stud and track roll forming machine have beautiful appearance and bright color.

They are widely used in gardens, factories, resorts, hotels, exhibition halls, vacationlands,

ancient architectures and modern villas.

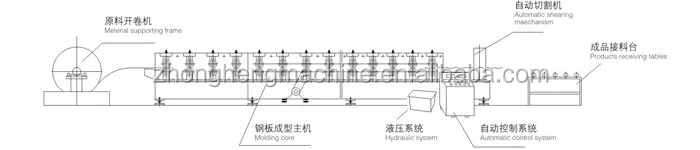

2). Working Flow of Drywall metal stud and track roll forming machine

Decoiling the sheet-Sheet guiding-Roll forming-Measure length-Cutting the panel-Panels to the supporter

(3).Technical Detail

A Sheet Specifications

| 1 | Coil Type | PPGI GI |

| 2 | Width | 500mm |

| 3 | Thickness | 0.3-0.8mm |

| 4 | Yield stress | Q235 |

| 5 | Effective | 235mm |

B Components Details

| Roller Material | High grade 45# steel. Hard chrome plating, 0.05mm. |

| Main Frame | 350# steel. More stable and no shaking. |

| Middle Plate |

16mm. We use thicker plates to ensure stability of our products. |

| Forming Steps | 15, according to the drawing. |

| Shaft Material | Φ70 mm, high grade 45# steel. |

|

Treating process: tempering- finish turning, high rigidity, hard to deform. |

|

|

Cutting Blade Material |

Cr12, hardness HRC60-62. |

| Treating process: heat treatment- plane abrasion- wire electrode cutting. |

C. Electric Components

| Suitable Power | 380V, 50 Hz, 3 phase or according to your need. |

| Screen | 7 inch touch screen, easy to operate. |

| PLC | Delta DVP 14ES |

|

well-adapted to various conditions, such as moisture, electromagnetic disturbance. |

|

| Frequency Converter |

Delta VFD-M. It has the advantage of slowing down before cutting, to ensure the length accuracy (±1mm, far better than industrial standard ±3mm). |

|

Length Measurement Device |

Omron, made in Japan. |

| It features with high accuracy and stability. |

| 2. More Pictures of Drywall metal stud and track roll forming machine |

| 3 Application of Drywall metal stud and track U channel roll forming making machine |

It can be widely used in village, hotel, exhibition, vocation vallage, family construction and outdoor decorate.

| 4. We have other Roll Forming Machine for your reference |

We provide an extensive line of products, including: roof and wall panel machine, tile roof machine, purline forming machine,

shutter door machine, floor decking machine and other associated equipment.

Our roll forming machines are equipped with PLC control to ensure high accuracy and easy operation.

| 5.About ZHONGHENG |

CANGZHOU ZhongHeng Machine Manufacture Co.,ltd is a professional manufacturer and exporter which has its own factory and also cooperate with several production factories and associated enterprises, concerning with the design, development and production of cold roll forming machines,material of building. We specialize in the automated production line of sheet cold roll forming machines. We are able to provide an integral resolution schema of cold roll forming system through a combination of advanced system design and equipment. Based on our advanced research and commercial team, we are able to research and development, manufacturing and sale of standard and non-standard cold roll forming equipment for our clients world widely.

| 6. We provide shipping service for Roll forming machines |

1. light gauge steel channel frame metal stud and track roll forming machine need one 20/40 feet container to load .

2.We have professional technicians for loading to make sure machine has no damage.

3.Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you.

| 7. Terms and aftersale service |

1.Payment Term: 30% paid by T/T as down payment, the rest 70% after inspection by buyer in seller’s factory while before delivery. After finished production, we will inspect the machine and inform the buyer, the buyer send person to inspect goods, then payoff the whole payment before shipping.

2.Delivery Time: We guarantees the equipment will be ready for shipment within 30 working days after receipt of deposit .

3.After sale Service: We could send technician to your country to install machine if you need. The buyer need to pay for all the cost, including: visa, round trip tickets, accommodation, salary of USD 100~120 per day.

4.Warranty: 12 months

During the warranty, the replaceable parts are free, but the buyers need to pay for the shipping . We will also provide you instruction manual to show you how to operate the machines.

| 8. FAQ |

1. Can you make the machine according to my design or photo type?

A: Yes. We have an experienced engineers to work out the most suitable design and production plan for the machine.

2: How can we be assured that you will deliver us quality machine with spare parts?

A:1. Customers to send the technical people to our factory for checking the quality.

2.We can send the technicians to the buyer`s factory for the installation and trainning .

3.What about your warrenty?

A: Within the One-YEARS period, we could supply you the replacement parts for free .

If any damaged parts caused by quality problems after two years,we will also help but customer pay the cost .

More information please call Rebecca anytime !

-

High speed metal roll forming machine and track

-

c light keel forming frame cad light steel machine

-

House light steel villa light steel keel forming machine

-

Electrical Cabinet Shelf Roll Forming Machine Using Elephant Roll Forming Technology

-

Light steel keel equipment keel rolling forming frame dividing machine

-

Popular c panel channel steel stud light weight keel equipment roll forming machine

-

metal frame for making drywall drywall, stud rolls, cu shaped light keel forming machine

-

Precast Concrete Fence H Beam Making Machine After Precast Concrete Fence

-

Gypsum Board Ceiling Steel Fur Channel Forming Machine Omega Channel Forming Machine

-

PLC controlled steel CZ purlin roll forming machine for quick replacement

Other Products

-

$11000.00 / set

$11000.00 / set