Micro drill string drilling and milling machine ZAY7045FG/1

-

Supplier: Shanghai HD M&E Tech Co., Ltd. -

Region: Shanhai, China -

Contact: Ms Julia Han -

Price: $1450.00 / 1 - 4 sets

$1400.00 / 5 - 9 sets

$1350.00 / >=10 sets -

Min. Order: 1 set

Product details

| Supply capacity: | 50 sets per month | End milling capabilities: | 32mm |

| Place of origin: | China Shanghai | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Marketing type: | normal product | maximum. Drilling diameter (mm): | 45 |

| type: | Drilling and Milling Machine | Power (kW): | 1.1 |

| Whether CNC: | normal | Video outbound inspection: | if |

| Showroom location: | not any | Health status: | new |

| Packaging details: | Taiwan Technology Inclined Bed CNC Lathe Price: Export Wooden Box | Weight (kg): | 325kg |

| Spindle travel: | 130mm | Distance from spindle nose to worktable: | 450mm |

| Packaging size (length*width*height): | 770*880*1160mm | Applicable industries: | Building material store, machine repair shop, home use, construction project, industry, factory |

| Voltage: | 380 | Motor Power: | 1.5kW |

| Milling capacity: | 80mm | brand: | SHHD |

| Table size: | 800*240mm | Core component warranty: | 1 year |

| Drilling capacity: | 45mm | Warranty: | 1 year |

| model: | ZAY7045FG/1 | Mechanical test report: | if |

| Spindle taper: | MT3, MT4 or R8 | port: | Shanghai/Dalian/Ningbo/Qingdao/Shenzhen/Guangzhou Port |

| Net weight Gross weight: | 325kg/365kg | Core components: | Bearings, motors, pumps, gears, PLC, pressure vessels, engines, gearboxes, others |

| Spindle speed range (rpm): | 80 - 1250 rpm | Package preview: | |

| Main selling points: | multifunctional | Dimensions (length*width*height): | 770*880*1160mm |

Product Description

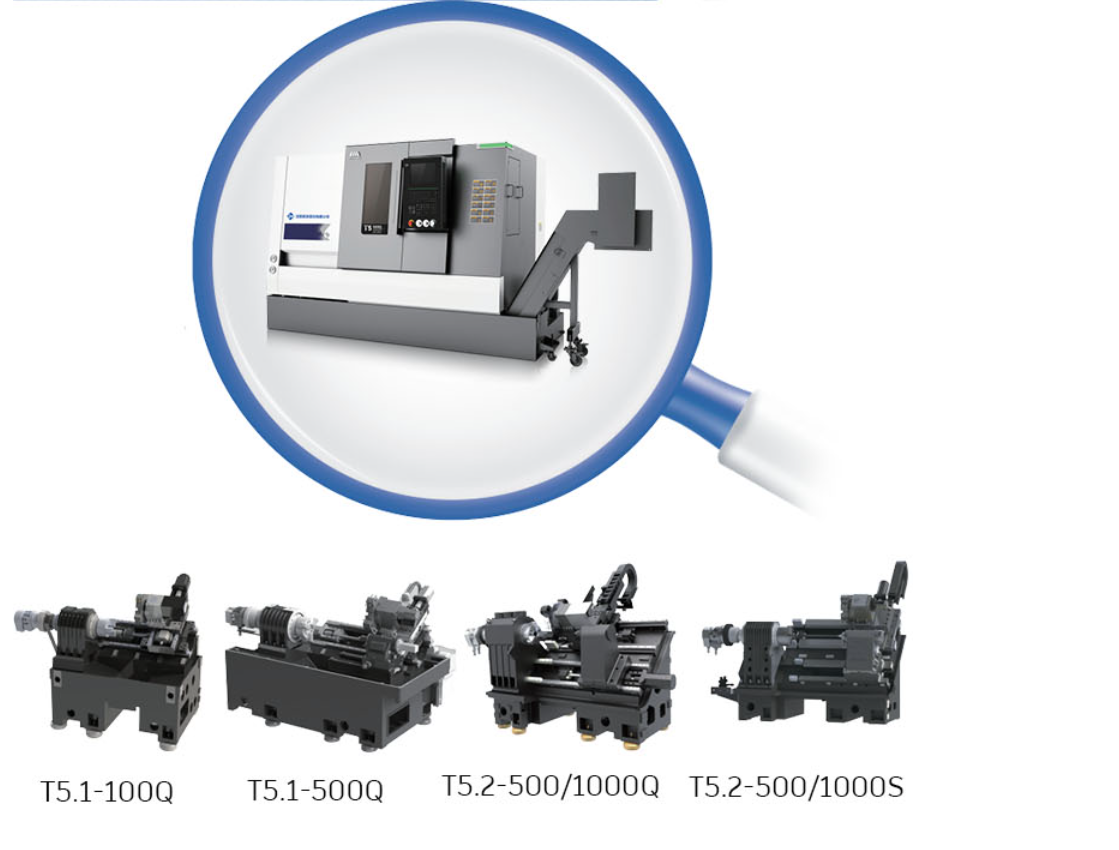

CNC horizontal lathe (T5 series)

T5Q series horizontal CNC lathe, combined with intelligent control technology and advanced manufacturing technology, has high precision, high efficiency and high cutting rigidity. Finite element analysis software is used to optimize the design, analyze stress point distribution, reduce part deformation, and optimize the entire machine structure. The main castings are made of high-strength cast iron materials, which ensures that vibration during the cutting process is minimized and improves machining accuracy and cutting stability.T5.1-Q seriesHorizontal CNC lathes occupy a small area and are suitable for high-precision processing of various small-sized parts, effectively meeting the processing needs of automobiles, bearings, hardware, medical and other industries.

T5.2-Q seriesHorizontal CNC lathes are suitable for processing various shaft and disk parts, effectively meeting the processing needs of football cages, automobile spindles, motor gear shafts, valve lifters and other parts.

T5.2-S seriesThe feed part of the horizontal CNC lathe adopts a hard rail structure and is highly rigid. It is suitable for processing various shaft and disk parts, and can effectively meet the processing requirements of automobiles, bearings, engineering machinery, etc.

industry.

industry.

Features

1. High precision❖ C3 pre-drawn screw ❖ Error compensation technology ❖ Process standard quantification

2. High efficiency❖ Two-axis high-speed and rapid movement ❖ Split servo tail ❖ High-efficiency servo turret

3. High rigidity❖ High-quality cast iron bed and other key castings ❖ Large-span double-row cylindrical roller spindle bearings ❖ Anti-bending saddle structure

Product parameters

thing | unit | T 5.1-100Q | T 5.1-500Q | T 5.2-500Q | T 5.2-1000Q | T 5.2-500S | T 5.2-1000S |

maximum. cutting diameter | mm | Φ160 | Φ280 | Φ360 | Φ360 | Φ380 | Φ380 |

maximum. cutting length | mm | 160 | 500 | 500 | 1000 | 500 | 1000 |

maximum. Swinging around on the bed | mm | Φ420 | Φ420 | Φ560 | Φ560 | Φ560 | Φ560 |

maximum. wiggle on slide | mm | Φ160 | Φ280 | Φ350 | Φ350 | Φ400 | Φ400 |

Spindle nose | A2-5 | A2-6 | A2-6 | A2-6 | A2-8 | A2-8 | |

front bearing diameter | mm | 90 | 100 | 100 | 100 | 120 | 120 |

Spindle taper and hole size | 1:20;Φ62 | 1:20;Φ70 | 1:20;Φ70 | 1:20;Φ70 | 1:20;Φ90 | 1:20;Φ90 | |

Spindle bore diameter | mm | Φ56 | Φ65 | Φ65 | Φ65 | Φ80 | Φ80 |

Rod maximum diameter | mm | Φ44 | Φ50 | Φ50 | Φ50 | Φ65 | Φ65 |

Chuck size | inch | 6 | 8 | 8 | 8 | 10 | 10 |

Spindle speed | RPM | 5000 | 4500 | 4500 | 4500 | 4000 | 4000 |

Spindle torque | nanometer | 35 (2000 rpm) | 110 (769 rpm) | 136 (769 rpm) | 136 (769 rpm) | 180 (769 rpm) | 180 (769 rpm) |

Spindle maximum torque | nanometer | 70 (1500 rpm) | 180 (576 rpm) | 245 (576 rpm) | 245 (576 rpm) | 300 (576 rpm) | 300 (576 rpm) |

Main motor output Power on continuously/30min | kilowatt | 7.5/11 | 9/11 | 11/15 | 11/15 | 15/18.5 | 15/18.5 |

X/Z fast movement | m/min | 30 | 30 | 30 | 30 | 20 | 20 |

X-axis travel | mm | 145 | 160 | 200 | 200 | 200 | 200 |

Z-axis travel | mm | 205 | Chapter 560 | Chapter 560 | 1050 | Chapter 560 | 1025 |

Tailstock travel | mm | 300 | 500 | 950 | 350 | Chapter 770 | |

Drive mode | body | Servo drive | Servo drive | body | body | ||

Quill stroke | mm | 100 | 100 | 100 | |||

Sleeve diameter | mm | Φ80 | Φ100 | Φ100 | |||

Tailstock taper | Morse code | MT-5 | MT-5 | MT-5 | MT-4 | MT-4 | |

Turret type | Horizontal 8 Position servo turret | Horizontal 8 position servo Toure | Horizontal 8 position servo Toure | Horizontal 8 position servo Toure | Horizontal 8 position servo Toure | Horizontal 8 position servo Toure | |

Center high | mm | 63 | 80 | 80 | 80 | 100 | 100 |

Rotate repeat positioning | Second. | ±1.6 | ±1.6 | ±1.6 | ±1.6 | ±1.6 | ±1.6 |

tools nearby | Yes | Yes | Yes | Yes | Yes | Yes | |

the distance between Spindle center and base plate | mm | 926 | Chapter 936 | 1015 | 1015 | 1015 | 1015 |

weight | Kilogram | 2600 | 3500 | 4200 | 4750 | 4300 | 5000 |

battery capacity | Kilovolt-ampere | twenty three | twenty three | No. 27 | No. 27 | 42 | 42 |

Overall dimensions (length x width x height) | mm | 1750×1650×1650 | 2300×1680×1650 | 2750×1890×1900 | 3620×1890×1900 | 2870×1890×1900 | 3750×1890×1900 |

Product Details

i5 intelligent system

__________

The i5 intelligent system is based on advanced motion control technology and network technology, and features industrialization, informatization, networking, integration, intelligent and efficient integration, intelligent operation, intelligent programming, intelligent maintenance and intelligent management.

Double fixed preload structure

__________

The X-axis has developed a double fixed support structure and uses a pre-drawn lead screw to effectively offset pre-tension deformation and temperature rise deformation. With a special sealing structure, it reduces the temperature rise of the lead screw, thus achieving high precision and high stability of machine tool feed. sex.

__________

It adopts high-quality imported C3 screw and H guide rail, and is directly driven by the servo motor to achieve excellent operating accuracy.

__________

A tailstock with a small spindle structure can be configured, equipped with tapered roller bearings and angular contact ball bearings, to improve the cutting rigidity of the end of the tailstock and ensure the cutting effect of long-axis parts.

Industry application

ClickSend inquiryFree custom solutions and drawings at the bottom of the screen

VIEW MORE

You may like

-

Efficient, reliable, durable and easy to operate DSZG 12/20/30 Parking Heater Automatic Drilling Machine

-

Metal Lathe Mill Combination CT300 HQ300 3 in 1 Benchtop Lathe with Digital Display Factory Price

-

Brand new unused portable column drill press for sale SP5216A-II

-

High-precision milling machine table drilling and tapping Z403 Z606 machine tool

-

China's best artesian well drilling rig 150m deep

-

American Taiwan HC (Y) series HC-900 radial drilling machine

-

DD703 cnc edm drilling machine

-

SJQ Gasoline Engine Water Well Drilling Rig/Household/Air Conditioning Well

-

Bench Top 5 Speed Pulley Drive Drilling Machine CE Qualified 13mm Chuck Bench Top Drilling Machine

-

SJQ 80m to 100m depth portable cheap small water well drilling rig

Other Products

-

$30000.00 / set

$30000.00 / set

Related Search

drilling and milling machine with 20mm capacity

drilling and milling machine zx7040

small cnc drilling and milling machine

automatic cnc drilling and milling machine

drilling and milling machine cnc system

motor for cnc drilling and milling machine

drilling and milling machines

cnc drilling and tapping machine_2

drilling and milling reamer suppliers

drilling and tufting machines