SuperbMelt Chain Metal Forming Solutions Gold Casting Rolling Mill Jewelry Chain Making Machine

-

Supplier: Longgang Superb Electromachinery Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Kelvin Lin -

Price: $20000.00 /set -

Min. Order: 1 set

Product details

| Applicable metals: | Gold, silver, copper, brass, bronze and their alloys | Place of origin: | Guangdong, China |

| Melting time: | 3-5 minutes | Packaging details: | Plywood boxes |

| Metal capacity: | 2-6kg | Certification: | ISO9001:2000, CE |

| Automatic level: | automatic | payment terms: | Letter of credit, wire transfer |

| Package preview: | temperature control: | by PID | |

| cool down: | Chiller or tap water | Mechanical capabilities: | 20000 |

| Supply capacity: | 200 sets per month | brand: | superb melting |

| strength: | 5.5kW | Product Category: | Gold chain making solutions |

| Health status: | new | weight: | 210-250kg, 100kg |

| Year: | 2022 | Key machines: | Metal casting machinery, coil slitting machines, metal coiling machines, wire drawing machines, annealing furnaces, gold chain making machines |

| Voltage: | 220V/three-phase 380V, 220 | Maximum temperature: | 1600℃ |

| port: | Shenzhen | technical support: | technical support |

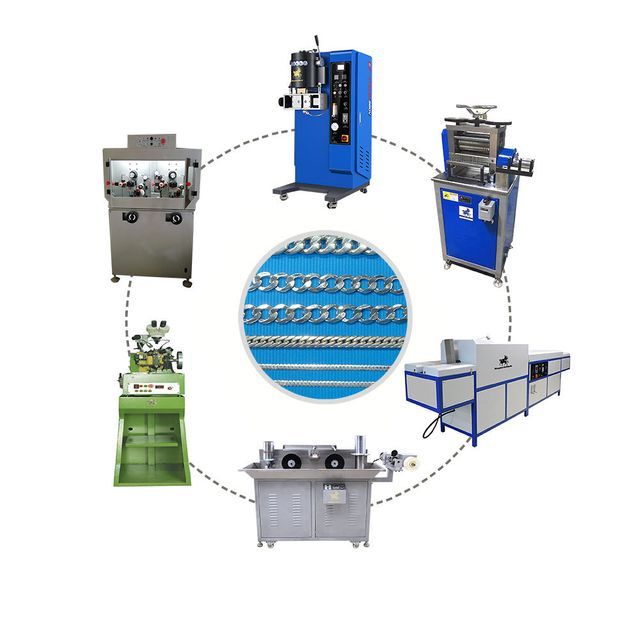

As a professional precious metal jewelry chain production solution provider, SuperbMelt has more than 10 years of experience. The types of jewelry chains we can make include trace chains, Belcher chains, horsebit chains, hay seed chains, snake chains, bead chains, rope chains, Figaro chains, etc.

We at SuperbMelt are committed to providing top-notch machines to make your jewelry chain making process faster and better. We are committed to helping industries keep up with the ongoing drive for innovation. We provide you with the perfect solution.

We at SuperbMelt are committed to providing top-notch machines to make your jewelry chain making process faster and better. We are committed to helping industries keep up with the ongoing drive for innovation. We provide you with the perfect solution.

solution

step 1:casting gold rod

model | SPB-LS4 |

energy source | Three-phase 380V, 50/60Hz |

strength | 15kW |

Maximum current | 15A |

Maximum capacity | 24K gold: 5.0 kg 18K gold: 3.5 kg 925 Silver: 2.5 kg |

melting time | 5 minutes |

Casting applications | Rod: φ4-φ20mm Pipe: minimum φ9*12mm, maximum φ52*60mm Rod: minimum T5*W5mm, maximum T20*W70mm |

Maximum drawing speed | 40cm/min |

aspect | 1120×840×1560mm |

weight | 195kg |

Protective gas | Nitrogen or argon |

Heating system | Induction heating |

temperature control | by PID |

Temperature accuracy | ±2 degrees Celsius |

go throughContinuous casting machine

A continuous casting machine casts the gold into rods. Using gas insertion melting protection technology, temperature control and stirring are accurately automatedStep 2:Roll the gold rod into filaments

model | SPB-YX-5P | |

type | 5.5P plate rolling machine | |

Power supply (V) | 380 | |

Power (kW) | 4 | |

Drum size (depth x length mm) | 105*200 | |

maximum. Thickness (mm) | 9 | |

Speed(rpm) | twenty four | |

Lubrication system | Automatic lubricant supply | |

maximum. rolling width | 190 | |

Wire rod rolling size | / | |

Dimensions (mm) | 530*600*1380 | |

Weight (kg) | 270 |

go throughJewelry tumbling machine

The Superbmelt electric rolling mill is designed to roll the thick gold bars produced into very fine wire rodsStep 3:drawing filigree

Model | SPB-6 wavelength division multiplexer |

energy source | Three-phase 380V, 50/60Hz |

strength | 2.2kW |

application | Shrinkage rate of gold, silver and copper wires |

Mold capacity | 6 pieces each time |

Wire diameter range | 2.2mm→0.2mm |

drawing speed | 0-50m/min |

aspect | 1800*700*1230mm |

weight | 370kg |

cooling method | Automatic liquid cooling |

Weight/kg | 660 |

go throughDrawing Machine

The wire drawing machine draws the thick wire into thin wire after wire drawing, and the wire diameter reaches the standard required for the production and processing of jewelry chains.

Step 4: Annealing to soften the gold blank

model | SPB-AWF |

energy source | Three-phase 380V, 50/60Hz |

strength | 13kW |

maximum. temperature | 950℃ |

speed | Stepless speed regulation |

cooling method | water cooling |

used gas | ammonia |

work slot | 70*40 (width*length mm) |

Network bandwidth | 50mm |

aspect | 3000*600*1500 (width*length*height mm) |

Weight/kg | 660 |

through annealing furnace

The annealing furnace is equipped with a high-performance ammonia decomposition hydrogen production system and PID intelligence. The heating process of the annealing furnace is completed under gas protection.

The temperature control has a 24-hour timer switch, which can quench various metals at the set temperature.

Annealing softens precious metal coins. However, precious metal coins will not oxidize or tarnish. Therefore, this meets appropriate processing standards.

Step 5:making jewelry chain

type | 450 high speed single, double and cross chain making machine |

Voltage | Single phase 220v |

strength | 200W |

Wire diameter | 0.19-0.45mm |

speed | 100-150 |

aspect | 420*750*550mm |

weight | 75kg |

work slot | 70*40 (width*length mm) |

Network bandwidth | 50mm |

aspect | 3000*600*1500 (width*length*height mm) |

Weight/kg | 660 |

go throughjewelry chain making machine

The filament is fed into the jewelry chain making machine, and the jewelry chain is woven through winding, cutting, welding and other processes.

Step 6:Faceted jewelry chain surface

go throughJewelry chain faceting machine

Jewelry chain faceting machine is suitable for mirror grinding, plane cutting, line, star, bevel, chamfer step cutting

Flat chain.

Superbmelt provides you with a one-stop solution for gold jewelry chain production line. Including on-site guidance, jewelry chain production equipment, and engineers to help you expand throughout the process. Our engineers have participated in the research of various styles of jewelry chains and served as technical consultants for major jewelry chain manufacturers.

If you are interested, please contact our sales immediately!

Our advantage

About SuperbMelt

1.Superb is a first-class professional manufacturer and exporter of precious metal smelting, casting and forming equipment. Its products are used in precious metals, rapid prototyping, jewelry and art sculptures and other fields.2. Our mission is to create the most innovative jewelry melting and casting equipment

Made of precious metals to provide the highest reliability and best quality for your daily operations.

3. As a leading precious metal melting and casting solutions provider, providing timely technical support to our manufacturers is an important part of our services. We have a strong technical support team of qualified and well-trained local (China) technicians dedicated to solving any problems you may encounter.

Customer photos

Powering an industry mired in the mundane means collaboration, dedication and a workforce built on shared values. Today, we are proud to be a major distributor of melting, casting and forming machines in more than 30 countries.

exhibition

purchase guide:

What is a gold chain making machine?

As the name suggests, this machine is used to make jewelry chains and the process is automatic. These machines are made of durable materials and can easily produce high-quality chains from different precious metals such as silver and gold. However, when purchasing a machine, do not forget to check the features of the machine.

What machines are used to make jewelry chains?

In the process of making jewelry chains, different types of machines are used for different purposes. Generally speaking, you need gold continuous casting machine, rolling mill, wire drawing machine, gold chain making machine, chain hammer and faceting machine. For all these things you can contact SuperbMelt. We offer machines for manufacturing different types of gold chains.

How are jewelry chains made?

All jewelry chains are made from wires made of different precious metals. Converting the wire to the desired diameter, the chain making machine will create the chain by threading the links to the previous links. Compared to traditional methods, it is impossible to make a chain in just a few hours. If you are looking for the best gold neckless making machine, you can always rely on SuperbMelt.

How are gold chains made?

The process of gold chain making is also called chain stitching, and using a gold chain making machine, the production process can be automated. Gold wire of a specific diameter is passed through a chain-making machine, creating beautiful patterns from its fragments and interconnecting the finished sections of the gold chain. These machines are so powerful that they can make a gold chain with about 600 links in 1 to 2 minutes.

Where did the gold chain come from?

According to data, the history of the chain can be traced back to around 2500 BC. During that time, the ancient Egyptians began stringing together silver and gold. At that time, gold resources were abundant, and people gradually developed gold pendants and wore them with gold chains. In 300 BC, the upper classes wore luxurious gold chains set with beautiful gemstones.

How much gold does it take to make a chain?

Well, it all depends on your requirements. The amount of gold varies depending on the weight and design. The weight of gold chains varies from 3 grams to 100 grams. You can go for more. However, generally speaking, around 10 to 50 grams of gold is enough to make men's jewelry.

How are necklaces made?

The process starts with a piece of wire. High quality wire is annealed in a furnace. Afterwards, the wire is processed by a straight knife to obtain the desired diameter. Next, the drawing process hardens the wire. Once completed, the wire is processed through a necklace making machine, which threads the wire onto the necklace to form a chain. The machine automatically creates chokers with ease, and your finished product will look stunning.

How are silver chains made?

Earlier, jewelers would make cast rings and join them together to form chains. However, since they use manual processes, this is a very time-consuming process. In fact, it is impossible to solder the loop in one piece in one day. That's why they started using a smelting process to create silver rods. Modern techniques include chain stitching. During this process, the silver thread passes through the mechanism, creating beautiful patterns from its fragments that interconnect the finished parts of the chain. A quality jewelry chain making machine can produce a silver chain with approximately 6,000 links in one minute. After going through the braiding process, the chain is coated with a unique material that makes it durable. It is then polished using a chain faceting machine.

How to make a silver chain smaller?

To shorten your silver chain, simply measure how many inches you need to remove from it. Then remove that section and reattach the clasp end to the rest of the chain. The process is simple and can be used to design simple chains such as ball chains or cable chains. However, when you choose an intricately designed silver chain, the process may look different.

Can a jeweler shorten the chain?

Yes, the chain can be shortened easily by a professional jeweler. However, shortening certain types of chains, such as stone-encrusted chains, snake chains, rope chains, etc., can be quite difficult. This process may take time. But a jeweler can do it for you as he/she has the best gold chain making machine.

How to make the chain longer?

Most chains are made from some standard jewelry material, such as gold or sterling silver, and range in width from 1 to 2 mm. To make a chain longer, a jeweler will source a perfectly matching section of chain and then attach it to the end of the chain, extending it to your desired length. However, with a fully automatic gold chain making machine, you can quickly create sections for your chain and use them to increase the length of your existing chain.

How to shorten the chain length?

Experts recommend that for best results, you should seek help from a jeweler. Jewelers are masters of their craft and know everything about chains. Additionally, they are equipped with the best automatic chain making machines that allow them to shorten the chain faster. They'll cut out the necessary parts exactly, put the clasp ends back on, and your chain will now fit you perfectly. You can even shorten the chain at home if you have all the necessary tools.

How are snake chains made?

Snake gold or silver chains are perfect for wearing with pendants. These chains are usually made of sheet metal rather than wire. These are tubular and smooth metal ropes. Snake chains are made from cut sheets, giving the chain a sturdy appearance. The panels combine to create a zigzag effect. Most snake chains come ready-made, that is, with a clasp attached.

How to shorten the links of a bracelet?

If you have a chain bracelet and it's too long for you, you can now easily shorten the bracelet to make it fit. To do this, you only need some simple tools and a high-quality bracelet making machine. First, you need to know how many links you need to remove. Now carefully bend the clip while holding the clasp. Remove them from both ends of the piece. Use wire cutters to cut these links. Now you need to reattach the jump ring to the new end link. You can use needle nose pliers for this. To ensure that the jump ring is installed correctly, you can use a jewelry hammering machine.

Are gold chains easy to break?

Well, it depends on the design of the gold chain. For example, hollow gold chains are lighter and cheaper, but they are weaker. Therefore, they are prone to breaking, denting, and kinking. If you want a durable gold chain, then a solid chain would be a good choice for you. Some of the strongest gold chain styles include Figaro chain, anchor or sailor chain, curb chain, wheat chain, cable chain, and more.

As the name suggests, this machine is used to make jewelry chains and the process is automatic. These machines are made of durable materials and can easily produce high-quality chains from different precious metals such as silver and gold. However, when purchasing a machine, do not forget to check the features of the machine.

What machines are used to make jewelry chains?

In the process of making jewelry chains, different types of machines are used for different purposes. Generally speaking, you need gold continuous casting machine, rolling mill, wire drawing machine, gold chain making machine, chain hammer and faceting machine. For all these things you can contact SuperbMelt. We offer machines for manufacturing different types of gold chains.

How are jewelry chains made?

All jewelry chains are made from wires made of different precious metals. Converting the wire to the desired diameter, the chain making machine will create the chain by threading the links to the previous links. Compared to traditional methods, it is impossible to make a chain in just a few hours. If you are looking for the best gold neckless making machine, you can always rely on SuperbMelt.

How are gold chains made?

The process of gold chain making is also called chain stitching, and using a gold chain making machine, the production process can be automated. Gold wire of a specific diameter is passed through a chain-making machine, creating beautiful patterns from its fragments and interconnecting the finished sections of the gold chain. These machines are so powerful that they can make a gold chain with about 600 links in 1 to 2 minutes.

Where did the gold chain come from?

According to data, the history of the chain can be traced back to around 2500 BC. During that time, the ancient Egyptians began stringing together silver and gold. At that time, gold resources were abundant, and people gradually developed gold pendants and wore them with gold chains. In 300 BC, the upper classes wore luxurious gold chains set with beautiful gemstones.

How much gold does it take to make a chain?

Well, it all depends on your requirements. The amount of gold varies depending on the weight and design. The weight of gold chains varies from 3 grams to 100 grams. You can go for more. However, generally speaking, around 10 to 50 grams of gold is enough to make men's jewelry.

How are necklaces made?

The process starts with a piece of wire. High quality wire is annealed in a furnace. Afterwards, the wire is processed by a straight knife to obtain the desired diameter. Next, the drawing process hardens the wire. Once completed, the wire is processed through a necklace making machine, which threads the wire onto the necklace to form a chain. The machine automatically creates chokers with ease, and your finished product will look stunning.

How are silver chains made?

Earlier, jewelers would make cast rings and join them together to form chains. However, since they use manual processes, this is a very time-consuming process. In fact, it is impossible to solder the loop in one piece in one day. That's why they started using a smelting process to create silver rods. Modern techniques include chain stitching. During this process, the silver thread passes through the mechanism, creating beautiful patterns from its fragments that interconnect the finished parts of the chain. A quality jewelry chain making machine can produce a silver chain with approximately 6,000 links in one minute. After going through the braiding process, the chain is coated with a unique material that makes it durable. It is then polished using a chain faceting machine.

How to make a silver chain smaller?

To shorten your silver chain, simply measure how many inches you need to remove from it. Then remove that section and reattach the clasp end to the rest of the chain. The process is simple and can be used to design simple chains such as ball chains or cable chains. However, when you choose an intricately designed silver chain, the process may look different.

Can a jeweler shorten the chain?

Yes, the chain can be shortened easily by a professional jeweler. However, shortening certain types of chains, such as stone-encrusted chains, snake chains, rope chains, etc., can be quite difficult. This process may take time. But a jeweler can do it for you as he/she has the best gold chain making machine.

How to make the chain longer?

Most chains are made from some standard jewelry material, such as gold or sterling silver, and range in width from 1 to 2 mm. To make a chain longer, a jeweler will source a perfectly matching section of chain and then attach it to the end of the chain, extending it to your desired length. However, with a fully automatic gold chain making machine, you can quickly create sections for your chain and use them to increase the length of your existing chain.

How to shorten the chain length?

Experts recommend that for best results, you should seek help from a jeweler. Jewelers are masters of their craft and know everything about chains. Additionally, they are equipped with the best automatic chain making machines that allow them to shorten the chain faster. They'll cut out the necessary parts exactly, put the clasp ends back on, and your chain will now fit you perfectly. You can even shorten the chain at home if you have all the necessary tools.

How are snake chains made?

Snake gold or silver chains are perfect for wearing with pendants. These chains are usually made of sheet metal rather than wire. These are tubular and smooth metal ropes. Snake chains are made from cut sheets, giving the chain a sturdy appearance. The panels combine to create a zigzag effect. Most snake chains come ready-made, that is, with a clasp attached.

How to shorten the links of a bracelet?

If you have a chain bracelet and it's too long for you, you can now easily shorten the bracelet to make it fit. To do this, you only need some simple tools and a high-quality bracelet making machine. First, you need to know how many links you need to remove. Now carefully bend the clip while holding the clasp. Remove them from both ends of the piece. Use wire cutters to cut these links. Now you need to reattach the jump ring to the new end link. You can use needle nose pliers for this. To ensure that the jump ring is installed correctly, you can use a jewelry hammering machine.

Are gold chains easy to break?

Well, it depends on the design of the gold chain. For example, hollow gold chains are lighter and cheaper, but they are weaker. Therefore, they are prone to breaking, denting, and kinking. If you want a durable gold chain, then a solid chain would be a good choice for you. Some of the strongest gold chain styles include Figaro chain, anchor or sailor chain, curb chain, wheat chain, cable chain, and more.

VIEW MORE

You may like

-

Stainless Steel Frying Pan Die Casting Cookware Frying Pan Production Line Ppl2 (3)

-

Hot Sale Low Noise High Speed Durable Nail Making Production Line Automatic Wire Nail Making Machine Price

-

Screw Bolt Making Machine Screw Production Line Factory Price

-

Aluminum Mug Stainless Steel Tumbler Aluminum Vacuum Thea Sports Mug Making Machine

-

Rebar Continuous Casting Mill Rolling Mill Production Line

-

Professional TYP 850 Horizontal Aluminum Extrusion Machine Production Line

-

Aluminum Production Line Factory, Aluminum Extrusion Machine, Aluminum Production Machinery

-

Factory price screw production line hobbing machine

-

Aluminum anodizing machine for aluminum profile production line

-

Fully automatic narrow strip slitting and rewinding steel radiator production line

Other Products

-

$5000.00 / set

$5000.00 / set -

$9000.00 / set

$9000.00 / set -

$9000.00 / set

$9000.00 / set -

$1200.00 / set

$1200.00 / set

Related Search

motorcycle chain making machine

rolling mill jewelry tools goldsmith

chain making machine

diamond chain making machine suppliers

chain making machine sale

auto metal form parts suppliers

metall form for toilet soap suppliers

cz metal forming machine

gold casting machine jewelry melting

pipe metal forming machinery