Steel Cable Tray Punching Making Machine

-

Supplier: Hangzhou Iuwon Technology Co., Ltd. -

Region: Zhejiang, China -

Contact: Mr Jason Wang -

Price: $100000.00 /set -

Min. Order: 1 set

| Packaging Detail: | Package for Cable Tray Roll Forming Machine: Machine Main Body is Naked, Other Components are Packed in Plywood Box.; | Dimension(L*W*H): | 30*4*4; |

| Thickness: | 1.8mm -2.0 mm; | Voltage: | AC380V,50Hz,3 Phase; |

| Hydraulic station power of Decoiler: | 3kw; | Suitable material: | Hot rolled steel coil/Galvanized steel coil; |

| Type: | Steel Frame & Purlin Machine; | Port: | Ningbo,Shanghai,Tianjin; |

| Condition: | New; | Supply Ability: | 10 Set/Sets per Month; |

| Power(W): | 60KW; | Production Capacity: | 6 m/min; |

| Warranty: | 1 Year; | Weight: | optional; |

| Payment Terms: | L/C,T/T; | Delivery Detail: | Three Months; |

| Coil width: | 194mm-408mm; | Brand Name: | IUWON; |

| Work Pressure: | 230-350Mpa; | Main motor power: | 11kw; |

| Model Number: | YCU-300; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Certification: | CE; | Place of Origin: | Zhejiang China (Mainland); |

Steel Cable Tray Punching Making Machine

Working Process

Decoiling→Leveling→Punching logo and holes→Servo Feeding→Punching long holes→Forming→Cutting→Outputting

Main Technical Parameter

Item | Para | Memo | |

Suitable Material | Type | Hot rolled steel coil Galvanized steel coil |

|

Thickness | 1.8mm -2.0 mm |

| |

Yield Strength | 235-300MPa |

| |

Coil Width | 194mm-408mm |

| |

Producing Speed | About 6 m/min | Including punching time and cutting time | |

Motor power of leveling device | 5.5 KW |

| |

Motor power of servo feeding device | 5.5 KW |

| |

Motor power of 110 tons punching device | 11 KW |

| |

Motor power of 250 tons punching device | 22 KW |

| |

Main motor power | 11KW |

| |

Roller change motor power | 1.5KW*2 |

| |

Hydraulic station power of Decoiler | 3KW |

| |

Hydraulic station power of Cutter | 5.5KW |

| |

Total power | 66.5KW |

| |

Power | AC380V,50Hz,3 Phase |

| |

Dimension (L×W×H, m) | About 30×4×4 |

| |

Profile Drawing

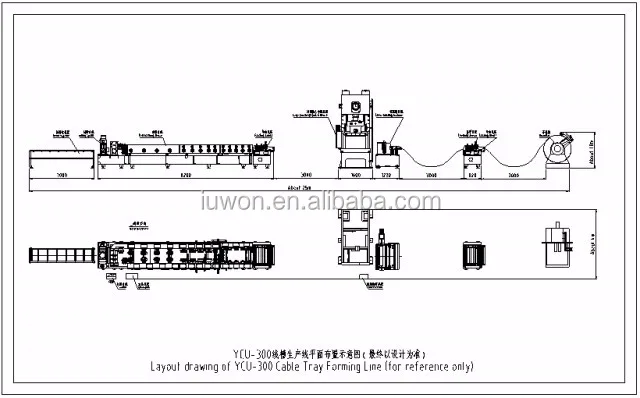

Layout

Installation (optional by the buyer)

a.After the machine arrives at the destination, the seller will send technician to the buyer’s factory to install the machine if the buyer wants. The buyer needs provide some technicians to assist the installation work.

b.Installation period(The buyer should have been prepared for the steel sheet, foundation position the machine before seller’s technicians departure): 5 days

c.The buyer pays the installation charges to the seller’s appointed account before the technician departure: USD1,000 per set.

d.Training period: 2 days. (we can supply training on the operation spot if buyer needs)

e.The buyer pays the seller’s technician: Travel cost outside China (including round flight charges), accommodation and foods (at least three-star hotel with air condition), solve the language problem, provide transportation from living place to the work place, and insurance out of China, etc.

f.With in 3 months after arrival of the goods at the port of destination, if there is no installment requirement from the Buyers, the goods should be counted as up to standard. Inspection standard is based on the technical standard signed by both parties and our company standard.

Terms of Payment

30% to be paid by TT as Down Payment,70% to be paid by TT before delivery.

Time of Shipment

90 daysafter down payment(Including Chinese New Year Holiday for 20 Days)

Guarantee of Quality

The Seller shall guarantee the goods with materials and workmanship in accordance with the required on the drawings, brand new, unused and correspond in all respects with the quality, specification and performance as stipulated in drawings and guarantee a good smooth operation for 12 months after date of shipment (except consumables). This guarantee excludes the parts that require the normal plant maintenance. The guarantee is strictly limited to the repairing and the replacing of the mechanical parts supplied by us found to be defective provided that failure has occurred during the ordinary use of the equipment and it is not accepted and claim due to damage to people, property or loss of production.

Our Factory

Exhibition

Certificate

1), Q: Do you have after sales support?

A: Yes, we are happy to give advice and have skilled technicians available across the world.

2), Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology to improve our machines constantly. We have experts from domestic-leading machinery corporation as well as sals elites.

Wokers, traders, designed as a family to insure best interest of our clints.

A: Quality is priority. IUWON people always attach great importance to quality control during the whole process. Every product will be fully assembled and carefully tested before packed.

4), Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.

Whatsapp/Mob:+86 18868400668

-

High speed metal roll forming machine and track

-

c light keel forming frame cad light steel machine

-

House light steel villa light steel keel forming machine

-

Electrical Cabinet Shelf Roll Forming Machine Using Elephant Roll Forming Technology

-

Light steel keel equipment keel rolling forming frame dividing machine

-

Popular c panel channel steel stud light weight keel equipment roll forming machine

-

metal frame for making drywall drywall, stud rolls, cu shaped light keel forming machine

-

Precast Concrete Fence H Beam Making Machine After Precast Concrete Fence

-

Gypsum Board Ceiling Steel Fur Channel Forming Machine Omega Channel Forming Machine

-

PLC controlled steel CZ purlin roll forming machine for quick replacement

Other Products

-

$2300.00 - $3000.00 / set

$2300.00 - $3000.00 / set