Manufacturer Fulund Solid Silicone 8 Inch Rubber Mixer Silicone Mixer With Best Price

-

Supplier: DongGuan FuLund Intelligent Technology Co.,Ltd -

Region: Guangdong, China -

Contact: Mr Jeff Su -

Price: $500.00 /set -

Min. Order: 1 set

| Total capacity(L): | 8 liters | Marketing Type: | 2019 Hot Products |

| Core component warranty: | 1 year | Warranty: | 1 year |

| Core components: | motor, water pump | Power (kW): | 7.5 kW |

| Dimensions (L*W*H): | 2700*1200*1600mm | Batch time (times/hour): | 100 times/hour |

| Package preview: | Applicable industries: | Clothing stores, manufacturing plants, food and beverage plants, printing plants, construction works, energy and mining | |

| Showroom location: | not any | brand: | Flanders |

| Supply capacity: | 50 sets per month | Video shipment inspection: | not available |

| Main selling points: | easy to operate | Health status: | new |

| Applies to: | rubber plastic | Origin: | Guangdong, China |

| Packaging Details: | wooden frame | Weight (kg): | 2500 kg |

| port: | Yantian | Mechanical test report: | if |

| model: | Magnetic resonance imaging | payment terms: | L/C, Western Union, T/T, MoneyGram |

| Voltage: | 380V |

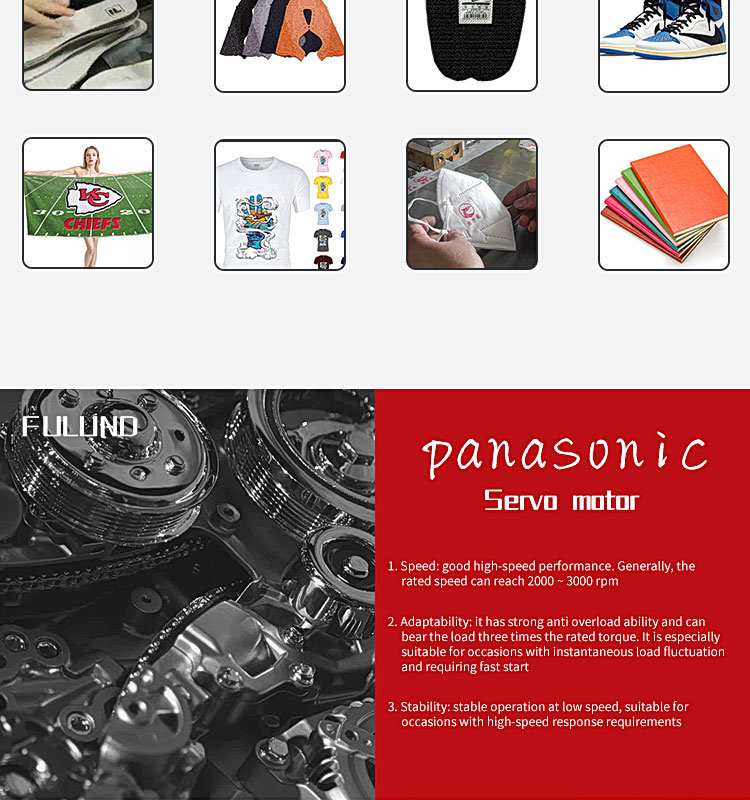

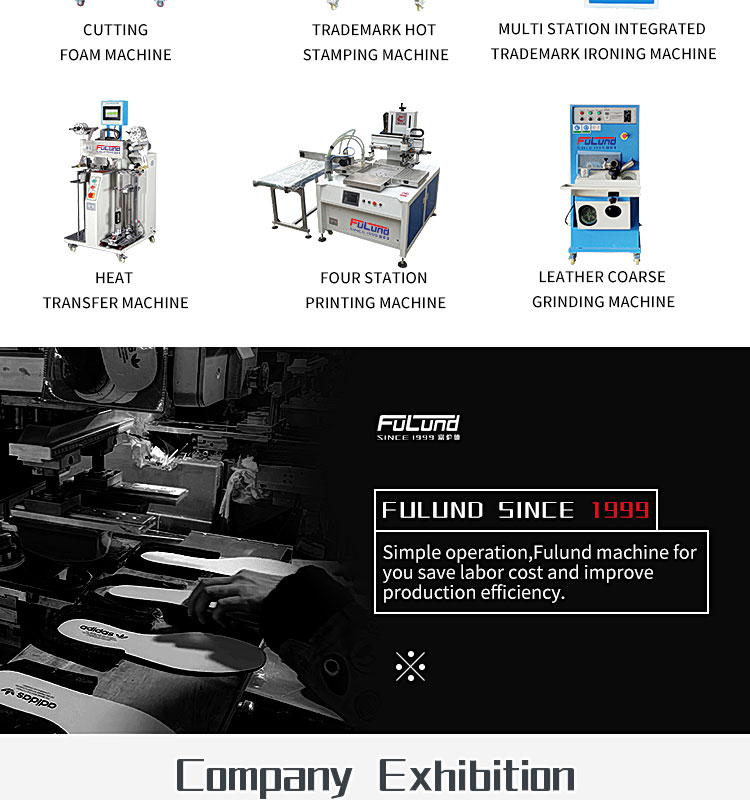

Fulund has a long history since its establishment in 1999. Due to development needs, the original brand (TYL) will expand the new brand Fulund in 2022. Fulund has customers all over the world, such as international brand shoe manufacturers.

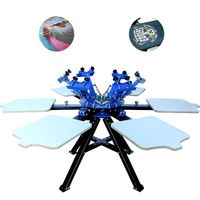

Fulong's main products: hot stamping machine, foam cutting machine, midsole hot stamping machine, tongue transfer hot stamping machine, midsole heat transfer machine, midsole cutting and transfer machine, midsole printing machine, silk screen printing machine, embossing machine, soft rubber equipment, vacuum vulcanizing machine, silicone labeling machine, dispensing machine, etc.

main feature

1. The idler roller is made of alloy chilled cast iron (including split casting or alloy integral type). Their surfaces are hard and wear-resistant

2. Rolls are divided into hollow rolls and drilled rolls. Hollow rolls (hollow roll bored, usually spray-coated

Cavity heating and cooling is used). The hollow roll surface can be processed into smooth rolls, integral smooth rolls, partially grooved rolls, welded alloy rolls, etc. For high cooling or heating rates, optional circumferentially drilled rolls

3. Both ends of the roll are supported by double-row spherical bearings. The large machine adopts double bearings. Therefore, it has the advantages of stable operation, energy saving, low noise and long service life.

4. The whole series of mills are equipped with safety devices according to the new platform to protect the main components from damage

5. Rolling bearing lubrication: grease lubrication and oil lubrication are arranged in order

6. The transmission part adopts nylon pin shaft coupling to prevent the transmission part from being damaged due to overload

7. The reducer adopts a hard tooth surface reducer. Low noise, high transmission efficiency and long service life

8. The base is integral, and the transmission mode is airtight transmission, which is safe and convenient to use

9. The user can choose the raw material mixer according to the process

-

Tangential rotor rubber mixer

-

Rear door type feed mixer/rubber raw material kneader

-

Spiral rubber kneader, EPDM hydraulic compression Banbury mixer, internal mixer

-

75L internal mixer rubber kneader closed internal mixer

-

Internal mixer plastic processing

-

Chemical batching system Powder weighing system PVC, rubber industry additive batching system

-

Latest design lab using rubber kneader or Banbury mixer for rubber and plastics

-

1L 3L 5L 10L Rubber Laboratory Banbury Internal Mixer Rubber Kneader Mixer Laboratory Powder Rubber Processing Test Machine

-

2L Experimental Kneader Rubber Dispersion Banbury Internal Mixer For Laboratory Testing Internal Mixer

-

Banbury Internal Mixer 50L/75L/150L/Rubber Industry

Other Products

-

$100.00 / set

$100.00 / set -

$155.00 / set

$155.00 / set -

$1000.00 / set

$1000.00 / set -

$100.00 / set

$100.00 / set -

$100.00 / set

$100.00 / set -

$1000.00 / set

$1000.00 / set -

$1000.00 / set

$1000.00 / set -

$100.00 / set

$100.00 / set -

$100.00 / set

$100.00 / set -

$1000.00 / set

$1000.00 / set