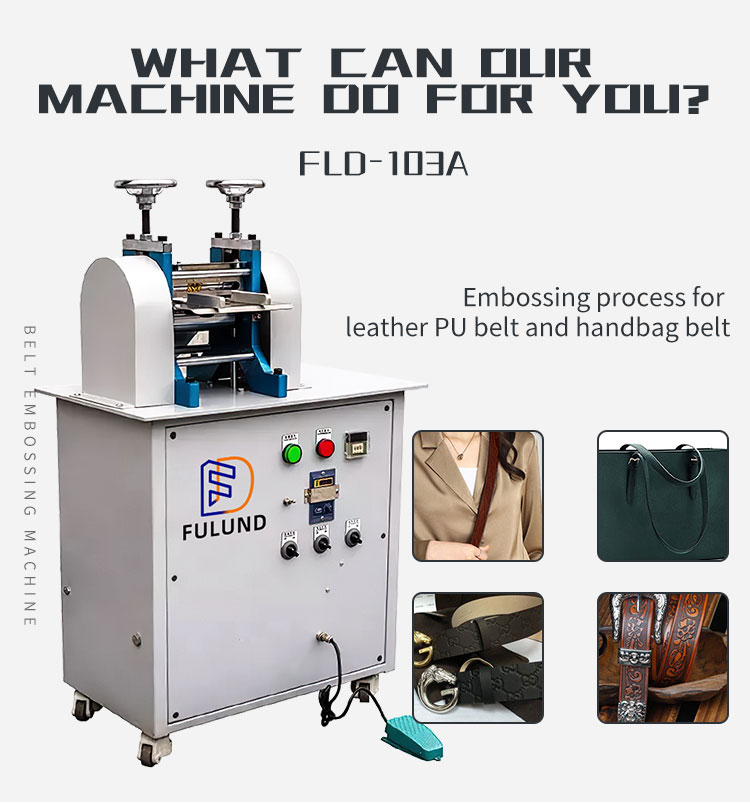

Leather ironing machine Leather warm roll electroplating embossing machine Belt belt making machine

-

Supplier: DongGuan FuLund Intelligent Technology Co.,Ltd -

Region: Guangdong, China -

Contact: Mr Jeff Su -

Price: $100.00 /set -

Min. Order: 1 set

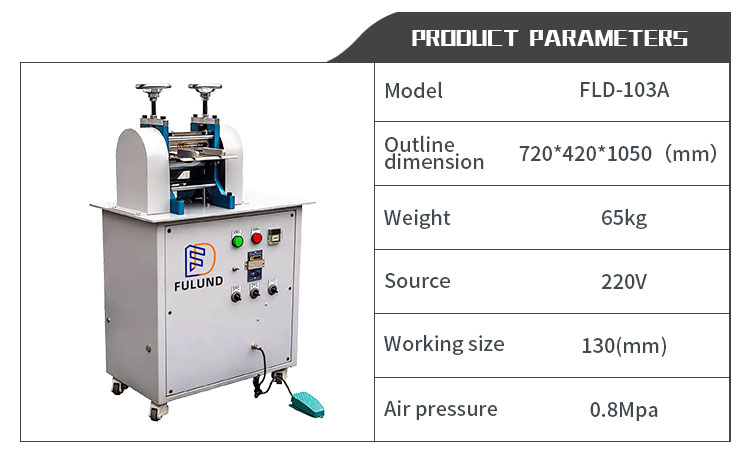

| it works: | leather goods production | Warranty: | 1 year |

| product name: | Pneumatic belt embossing machine | Packaging Details: | wooden box |

| Mechanical test report: | if | Marketing Type: | New Products 2022 |

| strength: | 1.1 kW | Types of: | Embossing machine |

| Showroom location: | not any | port: | Shenzhen |

| payment terms: | L/C, Western Union, T/T, MoneyGram | brand: | Furlong |

| Package preview: | Dimensions (L*W*H): | 720*420*1050mm | |

| Supply capacity: | 200 sets per month | weight: | 65 kg |

| place of origin; place of origin: | China | Automatic level: | semi-automatic |

| Voltage: | 220V | Video shipment inspection: | if |

| Core components: | Bearings, motors, PLCs | State of health: | new |

| Core component warranty: | 1 year | Applicable industries: | Clothing store, manufacturing plant, belt industry, luggage industry, footwear, etc. |

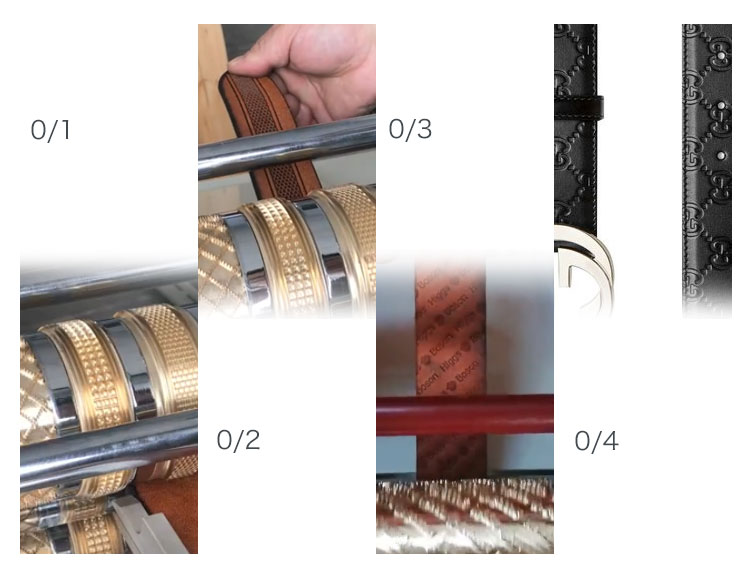

It is suitable for continuous branding, heavy deep branding, embossing, crimping and calendering of various long strips of leather. Frequency conversion speed regulation, oil pressure control up and down wheel lift

technical parameter:

Features of this machine:

1. With automatic feeding system, fast and accurate positioning, improving work efficiency.

2. The embossing time and temperature can be set, and the operation is simple.

3. With safety protection device, high safety.

4. With the operation of the mold, different molds can extrude different patterns, and the required temperature and speed can be adjusted according to different materials to achieve the color and depth of the imprint.

This machine is suitable for continuous branding of various long strips. With the operation of the mold, different molds can press out different patterns, and the required temperature and speed can be adjusted according to different materials to achieve the color and depth of the imprint. Pneumatic lower roller pressing design, material can be taken out smoothly during embossing.

-

Electric dual motor cutting machine press leather die cutting punching machine

-

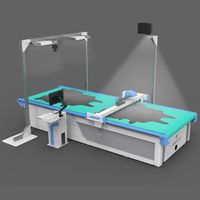

ZXT fully automatic digital industrial CNC genuine clothing natural leather cutting machine for sale

-

Leather strip cutting machine and tape folding machine

-

60 tons single side automatic feeding hydraulic round bubble cleaning/leather/sponge scrubbing/pad/die cutting machine

-

Jindex Sofa Upholstery Shoes Automatic Leather Cutting Machine, PU Pattern Automatic Knife Cutting Machine China Supplier Hot Sale

-

Horizontal belt edge dyeing machine leather men and women leather oil edge machine

-

Leather processing drum for full line leather production

-

Precision hydraulic leather belt embossing machine

-

VS925L Shoe Machine Atomic Refurbishment 25 Tons Swing Arm Cutting Press

-

ATOM Hydraulic Shoe Press Swing Arm Cutting Machine

Other Products

-

$100.00 / set

$100.00 / set -

$155.00 / set

$155.00 / set -

$1000.00 / set

$1000.00 / set -

$100.00 / set

$100.00 / set -

$100.00 / set

$100.00 / set -

$1000.00 / set

$1000.00 / set -

$500.00 / set

$500.00 / set -

$1000.00 / set

$1000.00 / set -

$100.00 / set

$100.00 / set -

$1000.00 / set

$1000.00 / set