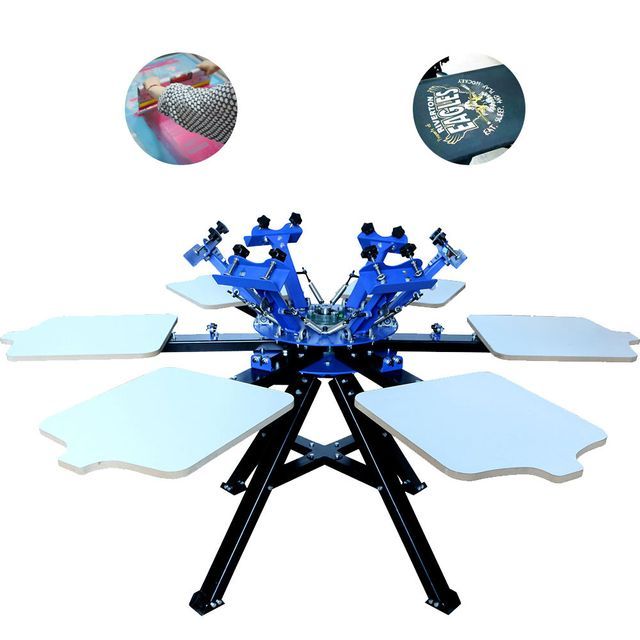

Manual multi-color custom screen printing machine micro-registered 6-color 6-station T-shirt screen printing machine

-

Supplier: DongGuan FuLund Intelligent Technology Co.,Ltd -

Region: Guangdong, China -

Contact: Mr Jeff Su -

Price: $155.00 /set -

Min. Order: 1 set

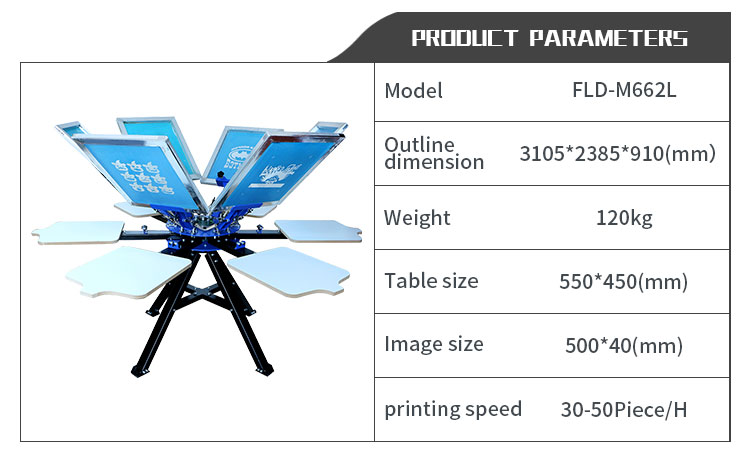

| usage: | Cloth printer, label printer, paper printer | Dimensions (L*W*H): | 3105*2385*910 mm |

| Applicable industries: | Clothing stores, manufacturing plants, others, printing shops | brand: | Flender |

| Automatic level: | manual | Certification: | CE and ISO |

| Key words: | screen printing machine | Origin: | Guangdong, China |

| Voltage: | 220V | Health status: | new |

| Mechanical test report: | if | Package preview: | |

| Main selling points: | easy to operate | port: | Shenzhen |

| color: | 6 colors | Supply capacity: | 200 sets per month |

| application: | Printed T-shirt | payment terms: | L/C, Western Union, T/T, MoneyGram |

| Core component warranty: | 1 year | weight: | 120 kg |

| station: | 6 stops | Core components: | motor, other |

| Packaging Details: | wooden box | maximum. print area: | 400*500mm |

| Colors and Pages: | Polychromatic | Video outbound inspection: | if |

| Warranty: | 1 year | Plate type: | screen printing machine |

Since its establishment in 1999, Fulunde has a long history. Due to development needs, the original brand (TYL) will expand the new brand Fulunde in 2022. Flood has customers all over the world, such as international brand shoe manufacturers.

The main products of Fulunde: hot labeling machine, foam cutting machine, insole hot stamping machine, shoe tongue transfer hot stamping machine, insole heat transfer machine, insole cutting and transfer machine, insole printing machine, silk screen printing machine, embossing machine, Soft rubber equipment, vacuum vulcanizing machine, silicone labeling machine, dispensing machine, etc.

Mainly used for six-color T-shirt overprinting, equipped with four frame chucks and six T-shirt tray stations;

The tray part and the screen frame part can be rotated 360 degrees independently, and the user can operate at any position;

Two users familiar with the machine can print 30-50 T-shirts per hour if a dryer is placed on the workstation to flash dry the surface.

This machine is manually moving screen frame color matching, all screen frame positions are correct for any pallet, and the other pallet will also be correct, and then the user can count the overprint. There is no need to correct the color position one by one.

Functions and Features:

-

Both the screen frame chuck and the pallet can be rotated 360 degrees, and the user can operate at any position or any pallet position.

-

Users can complete all frame overprint positioning at any pallet station. All frames are in the correct position for either tray, as is the other tray, and the user can start overprinting. There is no need to correct the position of each pallet.

-

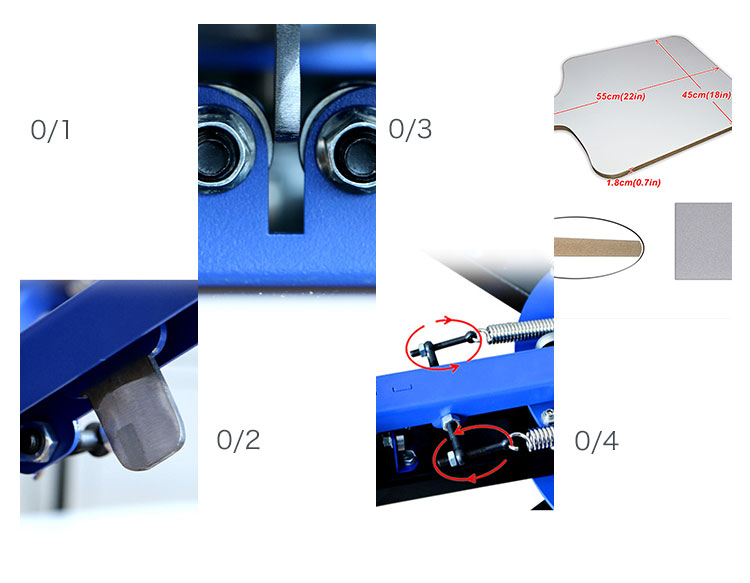

Each screen frame fixing device is equipped with precise positioning wheels, when the positioning iron on the screen frame is closely attached to the positioning wheels, the printing accuracy can be guaranteed.

-

Each screen frame fixing device is equipped with a large lock wheel, when the two large lock wheels are touched, the screen frame is easy to fall into the metal positioning wheel, and it can prevent the positioning iron from directly colliding with the metal positioning wheel.

-

Each screen frame fixing device is equipped with an adjustable height chuck positioning knob and an adjustable height knob when the screen frame is raised.

-

According to the weight of the screen frame, the spring tension can be adjusted through the turnbuckle to achieve balance.

-

The width of the screen frame chuck is (7.9in) 20cm, which is suitable for the screen frame whose outer dimension (20in) is within 50cm and the screen frame whose thickness is within 4cm (1.6in).

-

Depending on the height of the substrate, the frame clamps are adjustable up to 5 cm (2 in).

-

The tray is screwed directly to the tray arm.

-

The machine's T-shirt tray is 55 cm (22 in) long, 45 cm (18 in) wide and 1.8 cm (0.7 in) thick. It adopts melamine high-density board on the surface of furniture, with small pits on the surface, which is more suitable for scraping pallet glue when printing T-shirts.

-

This machine is a combined structure, a total of 4 boxes, small size, more convenient for transportation. The machine can be installed according to the installation diagram and configuration installation tools.

-

The machine adopts advanced electrostatic spraying technology, and all parts are made of stainless steel and aluminum alloy. Nickel plating, galvanizing technology, corrosion resistance, no fading, easy to clean, long-term color and smoothness, and can be used for a long time without rust.

-

All machines are equipped with a full set of tools to install the machine. The installation can be completed without preparing other tools. Equipped with installation diagram and packing list, the installation position of parts is clear at a glance. All machines are equipped with installation CD and operation video, which is more convenient for users to install and use the machine. There are also spare parts in the packing box for users to replace.

-

4-color 2-station single rotary printing machine

-

Six-color six-station double-wheel rotary screen printing machine series screen printing machine

-

Jiamei Hot Sale Wholesale Cylinder Manual Surface Screen Printing Machine Bottle Cup

-

Milk Tea Cup Brand Screen Printing Machine

-

2-color rotary screen printing machine / T-shirt / non-woven bags

-

Automatic screen printing machine

-

Manual Screen Printing Machine 6 Stations 6 Colors Manual Octopus Screen Printing Machine for Clothes

-

Paper Cup Automatic UV Screen Printing Machine PP PET Cup Screen Printing Machine

-

Manual wash station

-

S350 China Semi-Automatic Flat Round Oval Plastic Bottle Paper Cup Screen Printing Machine Printer Price

Other Products

-

$100.00 / set

$100.00 / set -

$1000.00 / set

$1000.00 / set -

$100.00 / set

$100.00 / set -

$100.00 / set

$100.00 / set -

$1000.00 / set

$1000.00 / set -

$500.00 / set

$500.00 / set -

$1000.00 / set

$1000.00 / set -

$100.00 / set

$100.00 / set -

$100.00 / set

$100.00 / set -

$1000.00 / set

$1000.00 / set