Food biotechnology industry three-effect forced circulation evaporator

-

Supplier: Vanoo(Shanghai) Machinery Equipment Co., Ltd. -

Region: Shanghai, China -

Contact: Ms Antonia Shu -

Price: $8000.00 /set -

Min. Order: 1 set

Product details

| capacity: | 10-5000 cubic meters/day | brand: | Vano |

| strength: | custom made | application: | pharmaceutical |

| port: | Shanghai/Ningbo Port | Health status: | new |

| Processing type: | juice | Warranty: | 1 year |

| Package preview: | place of origin; place of origin: | China Shanghai | |

| Key words: | Concentration equipment | Marketing Type: | New Products 2020 |

| Video shipment inspection: | if | Core component warranty: | 3 years |

| Supply capacity: | 10 sets per month | Voltage: | custom made |

| Mechanical test report: | if | Advantage: | efficient and durable |

| Applicable industries: | Food and beverage factories, pharmaceuticals, chemicals | After warranty service: | Video technical support |

| weight: | 12000 kg | Packaging Details: | We generally pack machines into soft containers, some into wooden boxes, and the most important ones, like some control systems, we will carefully pack into boxes. |

| Showroom location: | U.S. | payment terms: | L/C, Western Union, T/T, MoneyGram |

| Processing: | Concentrator | Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump |

| Dimensions (L*W*H): | custom made | Bale: | wood packaging |

Product overview

Multi-effect forced circulation evaporator

The forced circulation evaporator is a large-scale crystallization equipment with low energy consumption and energy saving developed by our company. It has the advantages of fast flow rate, high evaporation rate, high heat transfer coefficient, anti-salting out, anti-scaling, and not easy to scale. Widely used for materials with scaling, crystallinity, heat sensitivity (low temperature), high concentration, high viscosity and insoluble solids. Forced circulation evaporators can be divided into single-effect evaporators, double-effect evaporators and multi-effect evaporators. The forced circulation evaporator can be used for zero discharge of various salty wastewater, evaporation and crystallization of high COD wastewater, evaporation and crystallization of inorganic salts, evaporation and concentration of landfill leachate, etc.

List of functions

The system consists of forced circulation evaporator, separator (crystallizer), condenser, forced circulation pump, feed regulating valve, vacuum pumping and drainage system, sub-cylinder, operating platform, electrical instrument control cabinet, valves and pipelines.

1. Through forced circulation, the material liquid in the pipe is heated evenly, which can prevent the "dry wall" phenomenon; high evaporation rate, high concentration ratio, forced circulation makes the high-viscosity material liquid easy to evaporate and concentrate;

2. The flow rate of the circulating liquid in the heating tube is very high, which can avoid scaling or crystallization of the product due to boiling on the heating surface;

3. Due to the continuous maintenance of liquid circulation, the flow and temperature in the circulation pipe can be controlled to meet the requirements of different products without being affected by the set temperature difference;

4. The heating pipe can be vertical one-way, vertical two-way, horizontal one-way and horizontal two-way. The total height of the latter two types of equipment is small, but the pipe is not easy to clean and the pipe wall is easy to wear;

5. In the concentrated crystallization, by adjusting the circulation flow and adopting a special separator design, the crystal can be separated from the circulating crystallization liquid;

6. The power consumption and power consumption of the forced circulation evaporator are relatively high, and the heating temperature of the raw steam (primary steam) is also relatively high, so the heating area design of this evaporator should not be too large;

right level

left elevation

Front view

product specification

Model | single effect | double effect | Three effects | Four effects | |||

Feed amount (kg/hour) | 500-2000 | 2500-4000 | 3600-15000 | 8000-50000 | |||

Feeding concentration % | depends on customer | ||||||

emission concentration | depends on customer | ||||||

Pressure Mpa | about 0.5 | ||||||

kg/kg | 0.67 | 0.40 | 0.30 | 0.25 | |||

wire transfer | 29 | 12 | 9 | 8 | |||

degree | 45-90 | ||||||

product configuration

glass mirror

divider

heater

Machinery Seal

Heat Exchanger

spare parts

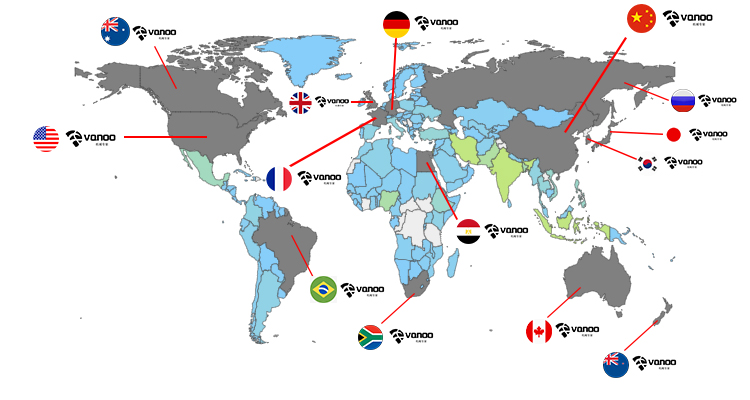

Sales and Service Network

successful project

Thailand project

Indian project

Russian project

VIEW MORE

You may like

-

stainless steel beverage vaporizer with low vaporization and concentration temperature

-

JH high-efficiency energy-saving alcohol distiller

-

Round/Spherical/Sphere Chinese Herbal Solution Juice Vacuum Concentrator

-

LABOAO laboratory and medical low temperature vacuum centrifugal concentrator

-

ZN Vacuum Evaporation Concentrator for Jam and Tomato Sauce

-

Food Processing Juice Evaporation Concentrator

-

Supply constant temperature vacuum concentration stainless steel vacuum evaporation concentrator

-

Stainless steel double-effect concentration evaporator ethanol alcohol evaporator juice concentration equipment

-

JH Whiskey Alcohol Distillation Equipment

-

JH Alcohol Recovery Distiller

Other Products

-

$8000.00 / set

$8000.00 / set

Related Search

flat plate solar collector forc circul suppliers

clean in place system for food industri suppliers

clean in place systems for food industry

japan food industry machines

forced air industrial convection oven

industrial forced convection ovens

industri food rotari dryer suppliers

single effect evaporator

triple effect evaporator

vegetable washing machine industrial for food industry