DB500 Wet Sandblasting Pot Sandblasting Tank Machine Water Shot Peening Pot DB800

-

Supplier: Qingdao Hezhi Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Mr Zhang -

Price: $930.00 / 2 - 2 sets

$850.00 / 3 - 4 sets

$700.00 / >=5 sets -

Min. Order: 2 sets

| Showroom location: | not any | Packaging Details: | 20'/40' container for blasting can machine |

| strength: | Depends on blaster model | Video external inspection: | if |

| Hose length: | 10 m | Applicable industries: | Hotels, Building Materials Stores, Manufacturing Plants, Mechanical Repair Shops, Farms, Retail, Construction Works |

| air pressure: | 6-7 bar | Certification: | Certification, ISO |

| weight: | 500 kg | Dimensions (L*W*H): | Depends on blaster model |

| After Warranty Service: | Video technical support, online support, spare parts, on-site maintenance and repair services | Type of machine: | Sandblasting machine |

| brand: | Hezhi | Local service location: | not any |

| Number of guns: | 1 | Fuel tank capacity: | custom made |

| Cleaning process: | sand cannon | Packaging Preview: | |

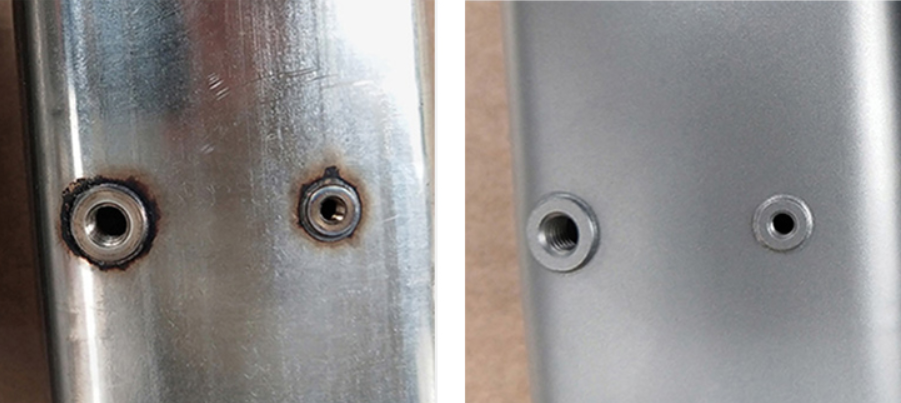

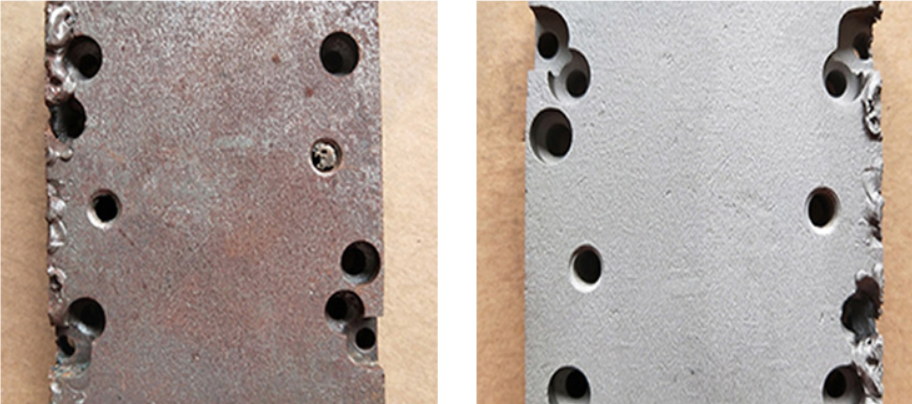

| Mechanical test report: | if | Function: | Remove and clean rust oil |

| port: | Qingdao/Ningbo/Tianjin/Shenzhen/Shanghai Port | place of origin; place of origin: | Shandong China |

| use: | Steel metal cleaning and sandblasting | Warranty: | 12 months |

| Marketing Type: | New Products 2020 | Cleaning Type: | Manual spray gun |

| Supply capacity: | 50 sets per month | Air consumption: | 6 m3/min |

| Blasting Hose Diameter: | ID32,OD48mm | Main selling point: | Professional team, competitive price and lifetime service |

| Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump | Blasting capacity (kg/h): | 1800-2200 |

| gasoline: | electrical | Material: | steel, metal, |

| Health status: | new | Core Components Warranty: | 1 year |

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram,for Sandblaster |

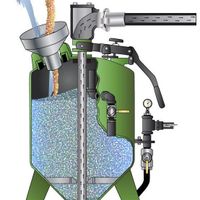

Portable water blasting tank is an essential tool for traditional corrosion-resistant operations such as ship maintenance, pipe and tank rust removal, and container renewal.

The cleaning effect of the workpiece. According to the requirements of work efficiency and abrasive size, the sandblasting tank of appropriate specifications can be selected. The automatic gun can be configured to clean automatically. All automatic portable industrial portable sandblasting pot cleaning equipment/sandblasting machines for sale are suitable for connection to pneumatic or electro-pneumatic remote control systems and pneumatic remote control systems, with blower and blower functions.

1. Structural steel cleaning6. Deburring2. Derusting of large equipment7. Pre-plating treatment3. Derusting on the surface of bridges and ships8. Pre-painting treatment4. Glass surface treatment9. Spray decoration5. Texture treatment of steel, carving, wood10. Descaling11. Refurbishment of car chassis

type | DB150 | DB225 | DB500 | DB800 | DB1500 | DB3000 |

capacity | 1 cuff | 2 cuffs | 5 cuffs | 8 cuffs | 15 cuffs | size 30 |

explosion time | 15 minutes | 30 minutes | 60 minutes | 90 minutes | 2-3 hours | 4-6 hours |

hose | 50 feet | 50 feet | 50 feet | 50 feet | 100 feet | 100 feet |

Weight kg | ~72 | ~120 | ~167 | ~194 | ~380 | ~554 |

compressor | 120CMF | 120 cubic feet per minute | 185CFM | 300+ CFM | 425+ CFM | 425+ CFM |

operational pressure | 30-150 psi | 30-150 psi | 30-150 psi | 30-150 psi | 30 to 150 psi | 30-150 psi |

blast hose | 15M | 15M | 15M | 15M | 30 meters | 30M |

1. Convenient abrasive filling, wheel structure, flexible movement

2. Electric control, pneumatic control, various control methods, long-distance fast control

3. The inner design of the hopper, the low hopper is easy to fill the abrasive

4. Simple operation, less investment and convenient maintenance

ISO9001 and CEobtain a certificate. full production,Quality Control(3 staff) andAfter the promotion(3 employees) Guarantee that the product is free of defects.3D Solidworksfor design. R&D staff more than20 years of professional experienceto meet your custom requirements.

Our philosophy: professional, efficient, loyal,

Our mission: to create core value for our customers, our employees and our company.

Choose Hezhi for ex-factory price and reliable shot blasting machine!

One. How many days will it take to produce this machine?

This is a specially designed machine according to your specific requirements. From engineer design to production completion, it

It takes about 10-20 days.

b. What does your factory do in quality control?

We have paid great attention to quality control from start to finish. Every machine is assembled and carefully tested

transportation.

C. What is your machine warranty?

The quality assurance period is one year. We select components from world-renowned brands to keep our machines in perfect working order.

d. Can installation and debugging be carried out overseas? How long will this take?

Yes, we provide overseas service, but the client needs to pay the engineer's air ticket and hotel, food.

Small machines generally take 5 days, and large machines generally take about 20 days.

e. How can I trust that you will deliver the correct machine the way I ordered?

As we discussed and confirmed in our order, we will definitely deliver quality machines. The core of our company culture is

Innovation, quality, integrity and efficiency.

f. How many operators are required to run the roller shot blasting machine?

1 operator.

For more questions please contact Anna, my phone number is 0086 1995325 9235

For more questions please contact Anna, my phone number is0086 1995325 9235

-

BY-1212 wet sand machine steam explosion machine wet sand blasting cabinet water steam machine

-

BY-1450-2A High-pressure sandblasting machine cleaning steel plate sandblasting machine

-

Manual Mini 100L/200L Sandblasting Tank Steel Shot Blasting Machine

-

Dust-free water blasting machine wet blasting machine blast tank DB 500

-

Micro dust-free sandblasting machine and dust-free sandblasting machine

-

New sandblasting cabinet portable sandblasting machine sandblasting machine

-

Rust and paint removal wet sandblasting machine

-

CE certified multifunctional sandblasting machine

-

Portable industrial sand breaker

-

Sandblaster Machine Sandblasting cabinet SBC1000

Other Products

-

$2800.00 - $3400.00 / set

$2800.00 - $3400.00 / set -

$1000.00 - $1500.00 / set

$1000.00 - $1500.00 / set -

$700.00 - $900.00 / set

$700.00 - $900.00 / set -

$2300.00 - $2500.00 / set

$2300.00 - $2500.00 / set -

$1500.00 - $3500.00 / set

$1500.00 - $3500.00 / set -

$2800.00 - $3400.00 / set

$2800.00 - $3400.00 / set -

$700.00 - $1000.00 / set

$700.00 - $1000.00 / set -

$6000.00 - $6800.00 / set

$6000.00 - $6800.00 / set