Large capacity 2000kg/hr PET bottle recycling line

-

Supplier: Jiangsu Mooge Machine Co., Ltd -

Region: Jiangsu, China -

Contact: Mr Michael Huang -

Price: $100000.00 / 1 - 4 sets

$98000.00 / >=5 sets -

Min. Order: 1 set

| Power (kW): | 450 | Voltage: | 380V 50HZ |

| Type of machine: | PET bottle washing line | place of origin; place of origin: | Jiangsu, China |

| Inverter: | delta | type: | PET bottle plastic recycling line |

| Warranty: | 1 year | Packaging Details: | Standard export packaging |

| Packaging Preview: | Production capacity (kg/hour): | 300 - 5000 | |

| Raw materials: | PET bottle waste | port: | Shanghai |

| thermometer: | Omron | After-sales service provided: | Engineers can repair machinery overseas |

| Marketing Type: | Hot Products of 2019 | After Warranty Service: | Video technical support |

| Showroom location: | Egypt, Turkey, United Kingdom, Brazil, Peru, India, Mexico, Russia, Thailand, South Korea, Bangladesh | Core Components Warranty: | 1 year |

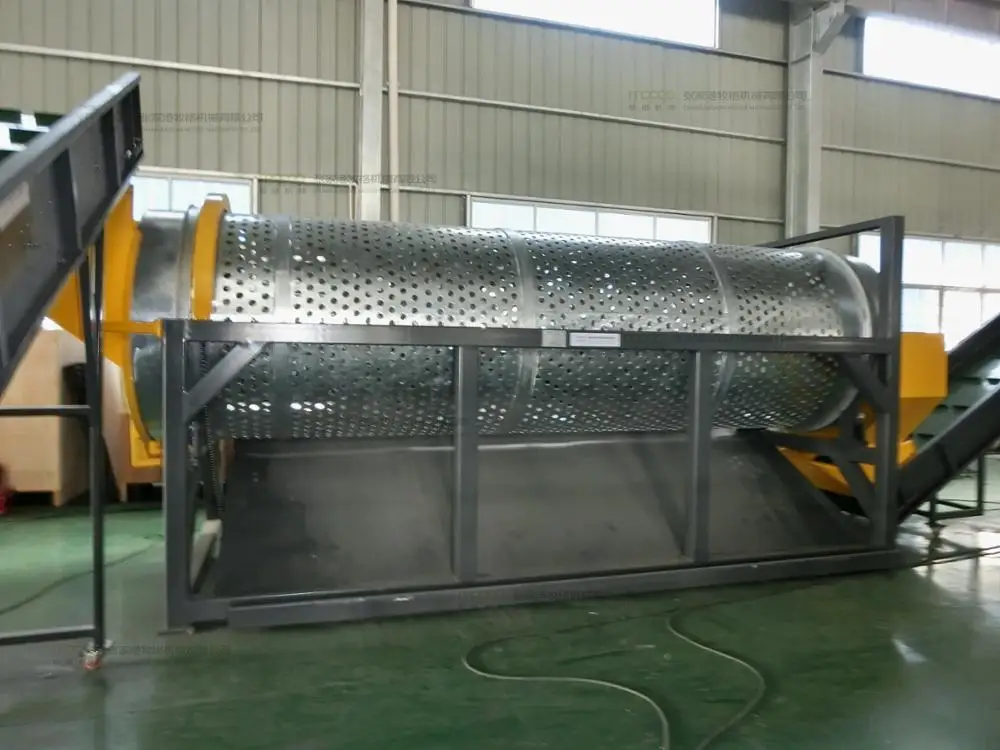

| Supply capacity: | 5 sets per month | Equipment List: | Drums, prewashers, bale openers, dehydrators, float wash tanks, hot air dryers, friction washers, label separators, label removers, hot wash tanks |

| Core components: | PLC, bearing, motor, gear | Main selling point: | High security level |

| Mechanical test report: | if | Applicable industries: | Manufacturing plant, plastic recycling plant |

| Video external inspection: | if | Weight (tons): | 20 |

| Finished goods: | Cleaning PET flakes | application: | PET bottle recycling |

| capacity: | 300/500/1000 kg/h | Hot wash tank: | optional |

| payment terms: | L/C,Western Union,T/T | Plastic Type: | pet |

| brand: | Moog Technology | Maximum production capacity (kg/hour): | 5000 |

| Auto grade: | automatic | service system: | Online support |

| Health status: | new | Dimensions (L*W*H): | 30m*2m*3m |

Large capacity 2000kg/hr PET bottle recycling line

Please select your desired capacity model;

We can manufacture production lines according to customer requirements and final sheet quality requirements;

Model | capacity | Installed power | water supply | area requirements |

MT-500 | 500 kg/h | 125KW | 4-5m³/hour | 55*3.5*4.5m |

MT-1000 | 1000kg/hour | 185KW | 5-6m³/hour | 55*6*3.5m |

MT-2000 | 2000kg/hour | 325KW | 10-12m³/hour | 80*6*5m |

MT-3000 | 3000kg/hour | 600KW | 20-30m³/hour | 100*8*5m |

MT-5000 | 5000kg/hour | 1000KW | 40-50m³/hour | 135*8*6.5m |

main feature

1. Unpacking and feeding system, uniform feeding, saving labor;

2. The manual sorting system can be used to sort out bottles of different colors and non-PET materials;

3- A metal detector is optional for removing any kind of metal from PET bottles;

4- The specially designed PET bottle crusher can easily obtain high output, and the wet mesh with water can prolong the service life of the blade and reduce the generation of dust;

5- High-speed dehydrator and drying system can ensure the moisture content of the final PET flakes is less than 1%.

6- The fin dust separator will remove the final label on the sheet to guarantee the PVC content.

Unpacking system — the unpacking machine breaks the bottles into loose bottles (optional) Four-axis design for higher efficiency

Label removal machine - separates labels and partial caps from plastic bottles, works with water, with a label separation rate of up to 95%

Dry or Wet Crusher - Reduces the size of plastic bottles into flakes. V-shaped rotor for higher output and lower power consumption

Hot and cold washing and separation tanks - material cleaning and density separation. Automatic scroll wheel increases efficiency

Chemical hot wash tank - removes oil and glue. Add caustic soda/detergent for cleaning, electric heating or custom

Friction Washer - Scrub material. RPM: 1440RPM or 1500RPM, high speed for good performance

High-speed dehydrator - removes moisture from products. Same design as friction washers, less than 1% moisture residue

Hot Air Drying System - Reduces the moisture content of the finished product. With electrical heating, the final flakes are dried and blown into the silo

-

Sevenstars PET bottle recycling machine/plastic cleaning machine/plastic recycling equipment

-

Best Price Waste Plastic PP PE ABS PS PET Recycling Pelletizing Machine Recycling Plastic Pelletizing Machine Production Line

-

pp woven bag recycling cleaning line plastic cleaning recycling machine garbage recycling plant

-

Waste plastic recycling line PET bottle flakes crushing and cleaning production line

-

Waste recycling machine for plastic bottles/pp pe recycling line for washing hdpe flakes

-

Plastic Recycling Machine Cost / Plastic Recycling Plant / Recycling Plastic Pelletizer Price

-

PET bottle recycling machine/plastic washing machine/plastic recycling plant

-

PP PE/PET Flake Washing Machine Floating Tank Floating Washing Machine for Plastic Recycling Washing Line

-

Polyester Fiber Recycled Making Machine/Waste PET plastic extruder machine/plant

-

Waste PET plastic bottle flakes washing recycling line/machine/plant

Other Products

-

$450.00 - $500.00 / set

$450.00 - $500.00 / set -

$85000.00 - $90000.00 / set

$85000.00 - $90000.00 / set -

$93000.00 / set

$93000.00 / set -

$450.00 / piece

$450.00 / piece -

$5000.00 / set

$5000.00 / set -

$195000.00 / set

$195000.00 / set -

$11000.00 / set

$11000.00 / set -

$20000.00 / set

$20000.00 / set -

$10000.00 / set

$10000.00 / set