High automatic 4-12mm ribbed steel bar cold rolled deformed steel bar making machine

-

Supplier: Anping County Second Barbed Wire Factory -

Region: Hebei, China -

Contact: Ms qian li -

Price: $6100.00 /set -

Min. Order: 1 set

Product details

| Local service location: | not any | Marketing Type: | New Products 2020 |

| Warranty: | 1 year | Applicable industries: | Building Materials Stores, Mechanical Repair Shops, Manufacturing Plants, Construction Works, Energy & Mining |

| weight: | 1.2-2.3 tons | Core Components Warranty: | 1 year |

| After Warranty Service: | Video technical support, online support, on-site maintenance and repair services | Health status: | new |

| Power (W): | 60KW | Wire: | 6.5/6.0/5.5mm wire |

| Voltage: | custom made | Packaging Details: | Bare full box, wooden box less: |

| Production capacity: | 245 m/min | Packaging Preview: | |

| Core components: | gear, motor | port: | Tianjin Xingang |

| Mechanical test report: | if | Main selling point: | high productivity |

| Supply capacity: | 20 sets or more per month | payment terms: | L/C,Western Union,T/T,MoneyGram,Credit card, Paypal |

| place of origin; place of origin: | Hebei china | application: | put up |

| Name: | Ribbed steel bar cold rolled deformed steel bar making machine | brand: | OLT |

| spare parts: | Drawing die | Showroom location: | not any |

| Video external inspection: | if | Inlet diameter: | 3.8mm |

| type: | Pulley Type | After-sales service provided: | Overseas service, online support, on-site maintenance service, video technical support |

Product Description

Every year you can see our company at the exhibition.

we are the manufacturerHebei Shijiazhuang near Beijing.Our newest airport isShijiazhuang Airport, welcome.

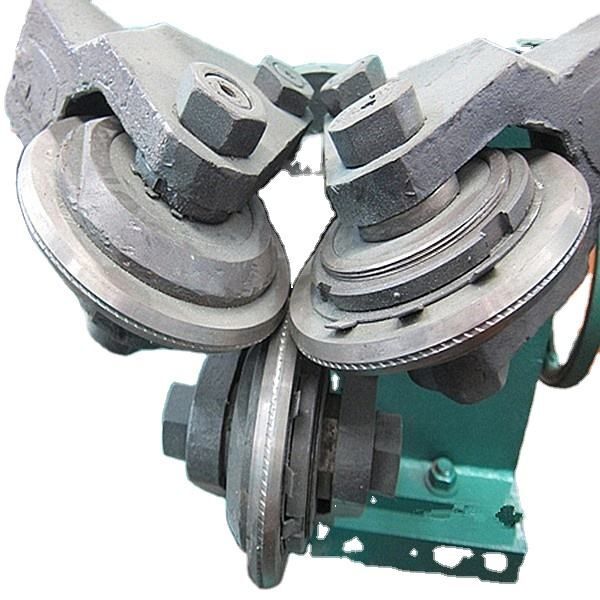

Ribbed steel bar making machine

This production line mainly rolls ordinary low carbon wire rods or low alloy wire rods with a diameter of 5-12mm. After many times of cold rolling and rib rolling, steel bars with three-sided crescent ribs are finally formed.

detailed image

Pull wheel wire drawing machine | ||||||||||||

type | Maximum inlet diameter (mm) | Minimum outlet diameter (mm) | drawing channel | Motor power (kw) | Production speed (m/s) | Production capacity (T/24h) | ||||||

OLT-4 | 6.5 | 3.8 | 4 | 15*4+1.5 | 100-120 | 12-15(3.8mm) | ||||||

OLT-5S | 4.0 | 2.0 | 5 | 7.5*5+1.5 | 150-200 | 5-6(2.0mm) | ||||||

Linear wire drawing machine | ||||

type | ZJ560-12+SP2+LM+XB | ZJ560-9+SP2+LM+XB | ||

Maximum incoming wire diameter | Φ6.5mm | Φ6.5mm | ||

Number of molds | 12 | 9 | ||

Drawing roller diameter | 560mm | 560mm | ||

Maximum speed | 12m/s (AC frequency conversion speed regulation) | 9m/s (AC frequency conversion speed regulation) | ||

Minimum outlet diameter | Φ1.2mm | Φ2mm | ||

Maximum uncoiler weight | 2.5T | 2.5T | ||

Maximum drum weight | 1T | 1T | ||

Inner diameter of winder | Φ560mm | Φ560mm | ||

Each drum motor | 18.5KW | 18.5KW | ||

Voltage | 380V 50Hz 240KVA | 380V 50Hz 185KVA | ||

total motor | 240kW/h | 185kw/h | ||

The finished wire has good electrical conductivity and firm welding. Used for galvanizing, it is easy to fluff when copper is plated, the amount of zinc applied is uniform and easy to control, and the finish is good. | ||

Parameters of water tank wire drawing machine | ||||||||||||

type | Maximum inlet diameter (mm) | Minimum outlet diameter (mm) | drawing channel | Motor power (kw) | Production speed (m/s) | Production capacity (T/24h) | ||||||

SX-1 | 4.0-3.5 | 1.8-1.4 | 8-10 | 37+1.5 | 150-200 | 5-8 | ||||||

SX-2 | 2.0 | 0.5-1.0 | 10-12 | 15+2.2 | 280-350 | 1-1.5 | ||||||

have any questions, pleasecontact ustimely.

VIEW MORE

You may like

-

Annealed wire high-speed linear drawing machine, galvanized wire winding machine

-

Monoblock drawing machine for steel bar drawing

-

wet drawing machine

-

Automatic Sheet Metal Polishing Deburring Machine Wide Band Sander For Cutting And Stamping Parts

-

Fire extinguisher barrel deep drawing hydraulic press

-

Cold Rolling Equipment Manufacture 3 Ribbed Steel Bar Machine

-

Small wire drawing machine for making copper wire

-

3 drum wire drawing machine / wire drawing machine

-

Low carbon steel straight wire drawing machine for wire binding

-

0.7mm-0.13mm kitchen Baibao wire drawing machine, stainless steel wire drawing machine

Other Products

-

$6100.00 / set

$6100.00 / set -

$2500.00 / set

$2500.00 / set -

$5800.00 / set

$5800.00 / set

Related Search

automatic steel nail making machine

milk chocolate bar making machine suppliers

steel drum making machine

steel frames making machine furring channel line

stainless steel noodle making machine cheap price

copper bar making machine suppliers

steel rebar making machine

steel pipe making machine

protein bar making machines

mini cereal bar making machine