Best price nail machine in China for Bangladesh, South Africa and Kenya

-

Supplier: Zhengzhou Uniwin Machinery And Equipment Co., Ltd. -

Region: Henan, China -

Contact: Mr Bruce Xia -

Price: $2000.00 /set -

Min. Order: 1 set

| Nail length range: | 1-6 inch nails/25-150mm nails | Motor brand: | Famous motor brand in China |

| Packaging Preview: | Main selling point: | high speed | |

| Production capacity: | 50 sets/month | place of origin; place of origin: | Henan, China |

| brand: | China uniwin wire nailing machine | Nail maker frame: | The reinforced frame structure ensures the fixation after tensioning. |

| Warranty: | 2 years | Packaging Details: | Best price nail making machine in China for Bangladesh, South Africa and Kenya, wrapped in plastic film and put in a wooden box to avoid damage during shipping |

| Applicable industries: | building materials store | Nail diameter: | 0.2mm-6mm |

| Power (kW): | 4 | speed: | 200-450 nails per minute |

| Nail making machine body and base: | casting technology | Supply capacity: | 30 sets per month |

| Health status: | new | Operation Type: | Automatic Wire Nail Making Machine |

| port: | Qingdao, Shanghai, Tianjin seaports, according to your requirements | usage: | Make 1-6 inch nails in different sizes. |

| After-sales service provided: | Online support, video technical support | payment terms: | Letter of Credit, T/T, Western Union, MoneyGram |

| Weight (kg): | 2000kg | export country: | South Africa Kenya Tanzania Ganha Uganda Nail Making Machine |

| Name: | Nail making machines in Bangladesh and South Africa and Kenya |

Best price nail machine in China for Bangladesh, South Africa and Kenya

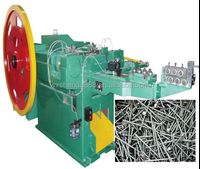

Description of the Wire Nail Machine

UNIWIN Nail Making Machine is specially designed for 1-6 inch nails, just feed the steel wire Q195/SEA1008/SEA1006/Q235 low carbon steel wire into the nail making machine and cut the steel wire into nails.

Features of Wire Nail Machine

The z94-4C series is our newly designed product with the following advantages:

1. Very low noise, the noise will not make people uncomfortable.

2.Wire Nail MachineThe main components (shafts, cams, gears) are made of high-quality steel and are professionally heat-treated to ensure a longer service life and less maintenance time for the nail making machine.

3. Automatic lubrication: Just add lubricating oil to the small oil tank, the machine can automatically lubricate the machine parts.

4. Bearing structure, longer service life.

5. EachWire Nail MachineSupply of nail molds, nail cutters, punching needles and other related spare parts.

Technical parameters of wire nailing machine

Nail making machine model | Z94-5C | Z94-4C | Z94-3C | Z94-2C | Z94-1C |

maximum. diameter nails | 5.5mm | 4.5mm | 3.1mm | 2.8mm | 1.6mm |

minute. diameter nails | 3.8mm | 2.8 mm | 1.8 mm | 1.2 mm | 0.9 mm |

maximum. nail length | 150mm | 100mm | 75mm | 50mm | 25mm |

minute. nail length | 80mm | 50 mm | 30mm | 16mm | 9mm |

Motor Power | 5.5kW | 4kW | 2.2kW | 2.2kW | 0.8kw |

Nail making speed | 220/min | 260/min | 320/min | 350/min | 450/min |

length*width*height | 2.5*1.8*1.5m | 2.2*1.6*1.65m | 2.0*1.4*1.4m | 1.9*1.356*1.4m | 1.55*1.3*1.1m |

weight | 2.2 tons | 2 tons | 1.5 tons | 1 ton | 750kg |

Whole nail making steel wire nail making machine process

The whole process of the manicure production line:Drawing---manicure making---polishing---nail packaging

1. Wire drawing machine - pull the wire diameter of 6.5mm/5.5mm into a smaller wire diameter, and make nails with wire diameters of 4.1mm, 3.4mm, 3.1mm, 2.5mm according to your requirements

2. Automatic Wire Nail Making Machine--- Feed the drawn wire into the nail making machine.

3. Polishing Machine - Polish the finished nails to remove dust and make the nails darker and shiny.

4. Wire nail packaging---pack the nails in carton or plastic bags, or in kraft paper bags such as 5kg, 10kg, 15kg, 20kg, 25kg nails.

Z94-4C series wire nailing machine:

The function of the nail making machine is to make the nails into different sizes by adjusting the nail making machine. It is necessary to put the appropriate wire diameter into the entrance of the nail making machine, and then start the nail making machine to automatically complete the nail making.

Detailed picture of wire nail machine structure

Our nail machines are reinforced with a heavier frame to keep the frame secure after tensioning. We pay more attention to the details of every small part, all these small details ensure the best quality of the nail machine so that it can function properly for many years.

Wire Nail Machinespare parts:

- Nail Art Mould/Grip Mould:

The clamping line is used for cutting by the nail knife to make nails of different diameters, and different nail molds need to be replaced. - Nail Clippers/Nail Clippers:Cut the wire and make the pegs.

- Pin/Hammer:Make nail heads. And the nail head can also be customized with the customer's simple logo.

Uniwin wire nailers will be packed in wooden cases and all nailers will be tested before delivery. After receiving the machine, it can be run by directly powering on it. You can choose the shipping method by sea, air or ground.

Customer visit

Customers are welcome to come to our factory to visit our nail making machine and its production process, and also welcome customers to bring material samples to our laboratory for testing, and talk with our engineers, and then choose a suitable filter press.

-

High-speed steel wire nail machine automatic low-cost nail/screw production line

-

Hot selling fully automatic wire nail production line/nail making machine

-

Pakistan High Speed Steel Wire Nail Making Machine/Kenya Nail Making Machine Manufacturer

-

800 pcs/min High Speed High Quality HD-90 Automatic Wire Nail Making Machine

-

High Speed China Automatic Thread Nail Machine Z94-4C

-

2022 Automatic common nail making machine to produce common steel nails low carbon steel wire with competitive price ISO and CE 10-127mm

-

Wooden peg automatic ordinary low noise nail making machine

-

Hot Selling 1 to 6 Inch Wire Nailer Z94 Series

-

APACHE High Speed Wire Nail Machine A-1C A-2C A-3C A-4C A-5C A-6C

-

Z94 Series High Speed Automatic Nail Making Machine Supplier

Other Products

-

$1000.00 / set

$1000.00 / set -

$2000.00 / set

$2000.00 / set -

$10.00 / set

$10.00 / set -

$3000.00 / set

$3000.00 / set -

$2500.00 / set

$2500.00 / set