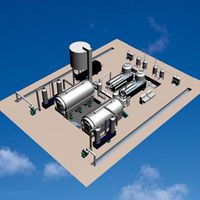

The latest technology small waste plastic diesel pyrolysis plant 10t/day

-

Supplier: Xinxiang Huayin Renewable Energy Equipment Co., Ltd. -

Region: Henan, China -

Contact: Ms Zora Xu -

Price: $30000.00 /set -

Min. Order: 1 set

| Weight (kg): | 25000kg | cooling method: | water cooling |

| Warranty: | 1 year | payment terms: | letter of credit, wire transfer |

| Heating material: | Coal, charcoal, wood, oil and gas | port: | Qingdao Port |

| Core Components Warranty: | 1 year | Reactor welding: | 3 welds |

| brand: | Huayin | Health status: | new |

| Cut: | automatic cutting machine | Quality test: | X-ray and supervised testing |

| Equipment capacity: | 10Tpd | Land Cover: | 300-400 square meters |

| raw material: | Scrap tires, rubber and plastic | place of origin; place of origin: | Henan, China |

| Core components: | Cracking reactor, condenser | Video external inspection: | if |

| welding: | automatic welding | Packaging Details: | 1*40HQ and 1*40FR |

| Applicable industries: | waste pyrolysis | Supply capacity: | 30 sets per month |

| cooling system: | Two large horizontal condensers | Mechanical test report: | if |

| Showroom location: | not any | Packaging Preview: | |

| Main selling point: | automatic | Workers needed: | 3-4 |

| Marketing Type: | New Products 2022 |

The latest technology small waste plastic diesel pyrolysis plant 10t/day

input raw materials

Waste pyrolysis equipment can process all kinds of waste plastics, including pp, pe, ps, abs, rubber products, tires to fuel oil, carbon black, steel wire.

|

About. Oil yield of different raw materials |

||

|

plastic

|

physical education |

50%-75% |

|

polypropylene |

50%-75% |

|

|

postscript |

50%-75% |

|

|

ABS |

40% |

|

|

leftover paper |

Wet 15-20%, Dry 60% |

|

|

house trash |

35-50% |

|

|

plastic cable |

80% |

|

|

plastic bag |

50% |

|

|

submarine cable |

75% |

|

|

rubber cable |

35% |

|

|

only |

30% |

|

|

PVC |

inappropriate |

|

|

pet |

inappropriate |

|

|

tire

|

car tires |

40%-45% |

|

truck tires |

45%-50% |

|

|

Motorcycle and Bicycle Tires |

25%-30% |

|

output product

1. Pyrolysis oil

- Direct use in industrial or boiler heating (eg cement plants, steel plants, glass plants, etc.) as an alternative to fuel oil.

- Refined into non-standard diesel for use in trucks, tractors, etc.

Note: The waste tire cracking plant directly produces heavy fuel oil, which can be directly used as industrial fuel. If you need to get diesel, you need a waste oil distillation plant.

2. Carbon black

- Can be compressed into pellets for industrial heating.

- It can be ground and refined to different standards.

3. Steel wire

- Sold to waste collection centers.

- Sold directly to steel mills for re-smelting.

1. Put the raw material into the reactor through the automatic feeder, and then heat the reactor. When the temperature is close to 250 degrees Celsius, do not stop heating the reactor, the waste tires will be transferred to the oil and gas.

2. The oil and gas are cooled into liquid oil by the condenser and collected by the oil tank.

3. The waste gas that cannot be cooled into liquid oil will be recycled to heat the reactor. The flue gas generated during the processing can meet the national emission standard through the double desulfurization and dust removal device.

4. After the end of oil production, cool the reactor for 3 hours, and the carbon black is automatically discharged.

Technical parameters of waste plastic pyrolysis machine

|

Model |

HY-05 |

HY-08 |

HY-10 |

HY-15 |

|

raw materials |

Scrap Rubber/Tire/Plastic |

Scrap Rubber/Tire/Plastic |

Scrap Rubber/Tire/Plastic |

Scrap Rubber/Tire/Plastic |

|

daily processing capacity |

5 tons |

8 tons |

10 tons |

15 tons |

|

work pressure |

normal pressure |

normal pressure |

normal pressure |

normal pressure |

|

host speed |

0.4 rpm |

0.4 rpm |

0.4 rpm |

0.4 rpm |

|

strength |

15 kWh |

15 kWh |

15 kWh |

15 kWh |

|

cooling method |

water |

water |

water |

water |

|

construction area |

200 square meters |

250 square meters |

300 square meters |

300 square meters |

|

heating mode |

direct |

direct |

direct |

direct |

|

oil production |

45%-50% |

45%-50% |

45%-50% |

45%-50% |

|

Noise decibel (A) |

<=85 |

<=85 |

<=85 |

<=85 |

|

Machine size (mm) |

D2200*L6000 |

D2200*L6600 |

D2800*L6600 |

D2800*L8100 |

|

Operating mode |

intermittent |

intermittent |

intermittent |

intermittent |

1. Delivery time- 10-15 days after we receive the deposit.

2. Warranty-The warranty period of the reactor and other parts except spare parts is 1 year.

3.Installation and Training-Our company sends one technician for each set of machine to guide your installation, debug the machine and train your workers.

-

Newly designed waste oil-to-diesel refinery

-

Fully Automatic Plastic Recycling Pyrolysis Diesel Tire Fuel Plant

-

Beston Group does not need to install a small pyrolysis machine for batch pyrolysis of 1-3T/D plastic tire oil sludge

-

Waste Tire Pyrolysis Diesel Plant Machine Manufacturer 5 Ton

-

Automatic control machine for biomass waste plastic tire pyrolysis machine

-

profitable small pyrolysis machine mini pryolysis plant

-

Small batch waste tire/plastic/MSW pyrolysis plant to convert solid waste into fuel oil pyrolysis machine 1-2 tons

-

New Design to Recycle Scrap Tires into Diesel with 50ppm Sulfur

-

Small integrated scrap aluminum and plastic pyrolysis plant provides fuel for machines

-

CE certified 15-50 tons automatic plastic pyrolysis plant continuous waste tire pyrolysis system

Other Products

-

$35000.00 / set

$35000.00 / set -

$38000.00 / set

$38000.00 / set -

$48000.00 / set

$48000.00 / set -

$40000.00 / set

$40000.00 / set -

$55000.00 / set

$55000.00 / set -

$45000.00 / set

$45000.00 / set -

$45000.00 / set

$45000.00 / set -

$40000.00 / set

$40000.00 / set -

$16000.00 / set

$16000.00 / set