New invention high quality used tire plastic pyrolysis machine

-

Supplier: Xinxiang Huayin Renewable Energy Equipment Co., Ltd. -

Region: Henan, China -

Contact: Ms Zora Xu -

Price: $45000.00 /set -

Min. Order: 1 set

| Product name: | waste plastic to pyrolysis oil used tyres into gasoline; | Raw material: | Waste Rubber Waste Tire; |

| Warranty: | 1 Year; | Key Selling Points: | Energy saving; |

| Material of Reactor: | Q245R /Q345R; | Structural form: | Horizontal Form; |

| After-sales Service Provided: | Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; | Port: | Qingdao/Shanghai; |

| Applicable Industries: | pyrolysis; | Cooling method: | Water Recycling Cooling; |

| Work Pressure: | Normal Pressure; | Function: | Tire Pyrolisis Plant; |

| Heating method: | Directly; | Brand Name: | Huayin; |

| Supply Ability: | 200 Set/Sets per Year; | Packaging Detail: | 40'FR and 40'HQ; |

| Certification: | CE,ISO; | Condition: | New; |

| Equipment Capacity: | 10tpd; | Payment Terms: | L/C,T/T; |

| Output: | fuel oil , carbon black ,; |

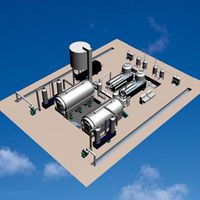

1. New invention high quality used tire plastic pyrolysis machine

Worldwide, it is estimated that 6 billion scrap tires are produced every year. Instead of burning the tires, the pyrolysis system roasts them at a lower temperature in an atmosphere devoid of oxygen (so that no actual burning will occur). This method of roasting is called pyrolysis, and is used for many different processes. By using pyrolysis, the tire shreds are broken down into their three basic components: carbon black char, steel radials and oil/gas.

2. 3D layout design

A step by step overview of the tyre pyrolysis process

The following steps broadly describe the tyre pyrolysis process:

1. Pre-treatment: Usually the tire diameter is within 1400mm, then no need pretreat the tires , we can feed the tires into the reactor directly with our auto feeder. if the tire diameter is above 1400mm , then the tires need to be cut into pieces by tire cutter.

2. Feed in system: The pre-treated tyres are loaded into a the auto feeding system where they are fed into the reactor.

3. Heating the tyres in the reactor: After the tyres are fed into the reactor, they are heated (or

‘cooked’) in the absence of oxygen. Each pyrolysis plant will follow its own heating

process. At lower temperatures more liquid products are produced and at higher temperatures

more gaseous products are produced.

4. This produces four products: The end products are a char, oil, syngas and scrap steel.

3. Details pictures of New invention high quality used tire plastic pyrolysis machine

1. The main product - fuel oil produced by our waste tyre pyrolysis machine is widely used for industrial and commercial purposes.With the heating value 10592.48Kcal/Kg, this fuel oil is a kind of good heating fuel which can be applied for boiler factory, cement factory,glass factory and steel mill, etc.

2. It also can be refined to diesel by the distillation machine. The distillation diesel can be used as diesel fuel used in diesel burners or diesel generators and some diesel engines.

| Item | Contents | |

| Model | HY2200mm*5500mm | 5 Ton/Batch |

HY2200*7500 | 7 Ton/Batch | |

| HY2600*6600 | 8 Ton/Batch | |

| HY2800*6000 | 9 Ton/Batch | |

| HY2800*6600 | 10 Ton/Batch | |

| Reactor material | Q345R/Q245R/310S+Boiler plate/Stainless steel | |

| Thickness | 14mm/16mm/18mm | |

| Weight | 15T-35T | |

| Power | Average 15KW/h | |

| Space needed | 300-400 square meters (Width:10m, Length:30m-40m) | |

| Labor needed | 3-4 workers | |

4. Packing and shipping for New invention high quality used tire plastic pyrolysis machine

1. Packaging Detail:

Needs 2*40HQ+1*40FR for delivery.

All goods are packed with exported standards package to make sure no damage during transportation.

2. Shipment: 25 days after the deposit

5.

Our machine have been exported to more than 65 countries all over the world including Romania , Itaian , Chile , Poland , Hungary , USA, England , Thailand, Greece, Mexico , Benin , Indonesia ,Dubai , India etc.

5. About us

Xinxiang Huayin Renewable Energy Equipment Co., Ltd located in xinxiang city , Henan Province ,we are a producer and seller specialized in research, development, production of waste tire/ plastic pyrolysis plant , waste engine oil /pyrolysis oil distillation to diesel plant , waste oil sludge treatment equipment. We have complete machining equipment, perfect process flow, powerful technical strength, excellent product development and design capability as well as rich production experience. Our company has been certificated to ISO9001 and CE international quality management system. Thanks to our excellent product quality and good after-sales service, our ptroducts have been exported far to European Union, Asia, Southest Asia , Africa , USA .

For more details , welcome send us inquiry !

Our service :

1.Huayin’s plants enjoy one-year guarantee, after which, we still offer lifelong technical support for your plant.

2. we will send engineer fo guiding installation , training workers , and trail operation.

3.For any tiny plant problem you cannot solve after one-year guarantee finishes, please feel free to Email or call our salespeople, who will wholeheartedly help you solve your problem.

For problems that cannot be solved via email or phone-call, our engineers may be dispatched to do plant maintenance and debugging until your plant resumes normal operation.

-

Newly designed waste oil-to-diesel refinery

-

Fully Automatic Plastic Recycling Pyrolysis Diesel Tire Fuel Plant

-

Beston Group does not need to install a small pyrolysis machine for batch pyrolysis of 1-3T/D plastic tire oil sludge

-

Waste Tire Pyrolysis Diesel Plant Machine Manufacturer 5 Ton

-

Automatic control machine for biomass waste plastic tire pyrolysis machine

-

profitable small pyrolysis machine mini pryolysis plant

-

Small batch waste tire/plastic/MSW pyrolysis plant to convert solid waste into fuel oil pyrolysis machine 1-2 tons

-

New Design to Recycle Scrap Tires into Diesel with 50ppm Sulfur

-

Small integrated scrap aluminum and plastic pyrolysis plant provides fuel for machines

-

CE certified 15-50 tons automatic plastic pyrolysis plant continuous waste tire pyrolysis system

Other Products

-

$30000.00 / set

$30000.00 / set -

$35000.00 / set

$35000.00 / set -

$38000.00 / set

$38000.00 / set -

$48000.00 / set

$48000.00 / set -

$40000.00 / set

$40000.00 / set -

$55000.00 / set

$55000.00 / set -

$45000.00 / set

$45000.00 / set -

$40000.00 / set

$40000.00 / set -

$16000.00 / set

$16000.00 / set