Good price automatic CE approved waste plastic recycling to diesel oil pyrolysis machine

-

Supplier: Xinxiang Huayin Renewable Energy Equipment Co., Ltd. -

Region: Henan, China -

Contact: Ms Zora Xu -

Price: $48000.00 /set -

Min. Order: 1 set

| Application: | Rubber Processing to Oil Machinery; | Equipment Capacity: | 10tpd; |

| Packaging Detail: | 40'FR and 40'HQ; | Video outgoing-inspection: | Provided; |

| Core Components: | PLC,pyrolysis reactor; | Condition: | New; |

| Payment Terms: | L/C,T/T; | Key Selling Points: | Automatic; |

| Working form: | Batch Operation; | Brand Name: | Huayin; |

| Machinery Test Report: | Provided; | Raw material: | Waste Tyre Waste Plastic; |

| Warranty: | 1 YEAR; | Package Preview: | ; |

| Showroom Location: | Canada,None; | Warranty of core components: | 1 YEAR; |

| Structural form: | Horizontal; | Applicable Industries: | waste pyrolysis; |

| Capacity: | 10TPD; | Port: | Qingdao/Shanghai; |

| Advantage: | High Efficiency; | Weight (KG): | 25000 KG; |

| Certification: | ce,ISO; | End product: | Fuel Oil Steel Carbon Back; |

| Oil yield: | 45%-50%; | After-sales Service Provided: | Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; |

| Marketing Type: | New Product 2020; | After Warranty Service: | Video technical support,Online support,Field maintenance and repair service; |

| Local Service Location: | None; | Supply Ability: | 250.0 Set/Sets per Year; |

| Material of reactor: | Q245R/Q345R Boiler Steel; | Reactor thickness: | 16mm; |

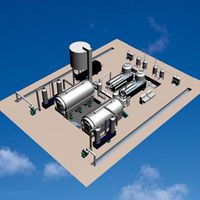

The introduction of HUAYIN waste tire /plastic pyrolysis plant

Used tires , scrap plastic, PP, PE , PS , aluminum foil , scrap PMMA etc raw material can be recycling pyrolysis to fuel oil , carbon black through pyrolysis machine .Compared with the burning or landfill , solve the waste problem by pyrolysis technology is more acceptable by people in the world , because it is fully environmental and can bring investors high profit .

The raw material and their different oil yield

|

pplicable Raw material |

Approximate Oil ratio |

|

Submarine cable |

75% |

|

Rubber cable |

35% |

|

Sole |

30% |

|

Big tires |

45%-50% |

|

Small tires |

35%-40% |

|

PP (microwave oven food box/yogurt bottles etc) |

50%-75% |

|

PE(plastic film /plastic wrap) |

50%-75% |

|

PS (smack-box/blister box) |

50%-75% |

|

ABS (engineering plastics) |

40% |

|

Leftovers of paper |

Wet 15-20%, dry 60% |

|

House garbage |

35-50% |

|

Plastic cable |

80% |

|

Plastic bag |

50% |

|

PVC (raincoat/building materials) |

Not suitable |

|

PET (water bottles/sodas beverage) |

Not suitable |

The OUTPUT product application of Huayin waste tire pyrolysis plant

From waste tire pyrolysis plant, 4 kinds of products can be obtained: fuel oil, catbon black, steel wire, and incondensable gas. Fuel oil is widely used in industries, such as steel factory, heavy oil generator, cement factory, and boiler heating etc. Carbon black can be made into pellets for making new rubber products. Steel wire could be sold to the recycle station or steel mill for remelting. The incondensable gas is recycled to heat the pyrolysis reactor, saving energy.

Working process

1. Put raw materials into reactor by auto-feeder, then heat the reactor. Do not stop heating the reactor when the temperature reaches nearly 250 degree Celsius, waste tyre will be transferred to oil gas.

2. The oil gas will be cooled by condenser to liquid oil then collected by oil tank.

3. The exhaust gas which can not be cooled to liquid oil will be recycled to heat the reactor. Smoke produced during processing can achieve national emission standard through dual desulfurization and dusting removal device.

4. After oil producing finished , give 3 hours for cooling the reactor,after that carbon black will be discharged automatically.

| Item | Contents | |

| Model | HY2200mm*5500mm | 5 Ton/Batch |

|

HY2200*7500 |

7 Ton/Batch | |

| HY2600*6600 | 8 Ton/Batch | |

| HY2800*6000 | 9 Ton/Batch | |

| HY2800*6600 | 10 Ton/Batch | |

| Reactor material | Q345R/Q245R/310S+Boiler plate/Stainless steel | |

| Thickness | 14mm/16mm/18mm | |

| Weight | 15T-35T | |

| Power | Average 15KW/h | |

| Space needed | 300-400 square meters (Width:10m, Length:30m-40m) | |

| Labor needed | 3-4 workers | |

Main Features of huayin waste recycling to oil machine

|

Energy-Saving:

|

|

|

|

Environmental Friendly

1. Emission Standard: Adopting special gas scrubbers.

2. Smell during operation: Fully enclosed during the operation. 3. Water pollution: During the operation, the water we use is recycling one to cool down the gas-oil and convert into liquid oil in the condensers. No pollution at all. |

|

100% Safety:

1. Adopting automatic submerged welding technology.

2. Adopting manufacture process controlling system. 3. equipped with temperature guage , pressure guage , auto alarm, auto pressure release,safety valve etc. safety devices. |

|

INSTALLATION CASES

our equipment has been exported to over 70 countries including Romania, Hungary, Turkey, Slovakia,Ecuador, Guatemala, Haiti, Mexico, Peru,Canada , USA,Jordan, UAE, Lebanon, Kuwait, Italian , Chile , Poland , England , Thailand, Greece, Mexico , Benin , Indonesia , India , Singapore ,Russia etc.

Installation case of pyrolysis plant

Packing and shipping

Our service

1. Delivery time- It will be 10-15 days after we receive the deposit.

2. Warranty-The warranty period for reactor and other parts except spare parts is 1 year.

The problem caused by wrong operation of workers shall not be responsible by our company.

3. Installation and Training-Our company will send one technician for each set of machine for guiding your installation, testing the machine and training your worker.

About us

Xinxiang Huayin Renewable Energy Equipment Co., Ltd is located in Xinxiang City, Henan Province, which is specialized in manufacturing waste tires/plastics to fuel oil pyrolysis machine and waste oil to diesel distillation machine since 1993. we have We have more than 2000 square meters running demo plant for customers' visitation and learning. our plants have been exported to over 70 countries around the world .

Why choose us

1. Qualified manufacturer and equipment with ISO and CE certificate;

2. Professional consulting team for offering free quote, market analysis and project guidance;

3. Technical department for providing technical support, project design and layout drawing;

4. Skillful engineering team for field installation, commissioning and operation training;

Related product

|

|

| Small pyrolysis plant |

-

Newly designed waste oil-to-diesel refinery

-

Fully Automatic Plastic Recycling Pyrolysis Diesel Tire Fuel Plant

-

Beston Group does not need to install a small pyrolysis machine for batch pyrolysis of 1-3T/D plastic tire oil sludge

-

Waste Tire Pyrolysis Diesel Plant Machine Manufacturer 5 Ton

-

Automatic control machine for biomass waste plastic tire pyrolysis machine

-

profitable small pyrolysis machine mini pryolysis plant

-

Small batch waste tire/plastic/MSW pyrolysis plant to convert solid waste into fuel oil pyrolysis machine 1-2 tons

-

New Design to Recycle Scrap Tires into Diesel with 50ppm Sulfur

-

Small integrated scrap aluminum and plastic pyrolysis plant provides fuel for machines

-

CE certified 15-50 tons automatic plastic pyrolysis plant continuous waste tire pyrolysis system

Other Products

-

$30000.00 / set

$30000.00 / set -

$35000.00 / set

$35000.00 / set -

$38000.00 / set

$38000.00 / set -

$40000.00 / set

$40000.00 / set -

$55000.00 / set

$55000.00 / set -

$45000.00 / set

$45000.00 / set -

$45000.00 / set

$45000.00 / set -

$40000.00 / set

$40000.00 / set -

$16000.00 / set

$16000.00 / set