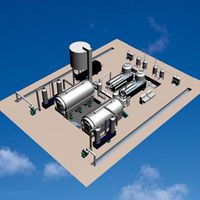

Newest pyrolysis of used tyres machines for recycling tire to fuel oil

-

Supplier: Xinxiang Huayin Renewable Energy Equipment Co., Ltd. -

Region: Henan, China -

Contact: Ms Zora Xu -

Price: $55000.00 /set -

Min. Order: 1 set

| Key Selling Points: | Energy saving; | Packaging Detail: | Nude packing for the reactor , wooden box for the small parts; |

| Material of Reactor: | Q345R/Q245R Boiler Steel; | End product: | Fuel Oil Steel Carbon Black; |

| Work Pressure: | Normal; | Port: | Qingdao/Shanghai; |

| After-sales Service Provided: | Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; | Machine Type: | Plastic Pyrolysis Euipment; |

| Applicable Industries: | waste pyrolysis; | Brand Name: | Huayin; |

| Fuels Choice: | Coal Gas Wood Oil; | Reactor thickness: | 16/18mm; |

| Payment Terms: | L/C,T/T; | Equipment Capacity: | 1tpd; |

| Cooling method: | Water Cooling; | Name: | Newest pyrolysis of used tyres machines for recycling tire to fuel oil; |

| Certification: | CE,ISO; | Raw material: | Waste Rubber Waste Tire Plastic; |

| Structural form: | Horizontial Rotation; | Warranty: | 1 year; |

| Condition: | New; | Supply Ability: | 220 Set/Sets per Year; |

Newest pyrolysis of used tyres machines for recycling tire to fuel oil

Advanced Pyrolysis Plant Converting Plastic Waste to Fuel Oil's oil recycling technology is widely recognized as one of the most economical and environmentally friendly methods. That’s because we can get some tire oil, steel wire and carbon black by using pyrolysis equipment.

Dependent on the needs of the market, these final products have wide range of applications. For example, tyre pyrolysis oil not only can be used as fuel oil in industries(such as steel and iron factories, ceramics, power or chemical industries or hotels, restaurants etc), but can be further refined into diesel or other. The carbon black from tires pyrolysis can be used for making construction bricks with clay or used as fuel. The steel wire can be sold directly or recycled to produce new steel products.

Features of the waste plastic pyrolysis plant

Environmental-friendly:

A. Emission Standard: a. Sync Gas Recycling System: Fully burned after recycling and utilization, saving fuel and preventing pollution; b. 3 layers of Ceramic packing deducting and water film smoke scrubber, efficient removal of the acid gas and dust of the smoke, environmental friendly to meet related national standards.

B. Smell during operation: Fully enclosed during the operation.

C. Water pollution: During the operation, the water is recycling to cool down the gas oil and to convert it into liquid oil in the condensers. No pollution at all.

D. Solid pollution: the solid after pyrolysis is the crude carbon black and steel wires which can be deep processed or sold directly with its value.

High degree of automation:

1) In manufacturing we use auto cutting machine, auto welding machine, auto rolling machine so that both quality and appearance of our products can be guaranteed.

2) In production, we use auto-feeder to feed raw materials into auto-feeder. By auto-feeder it needs few workers and less time to feed. And because of 50 ton hydraulic pressure from auto-feeder, it can feed more tires than labor.

For capacity ,We also provide 5 ton , 6 ton , 8 ton , 10 ton ,12 ton ,15 ton batch type machine.

Specification

Item | Detail | Detail | Detail |

Type | HY-05 | HY-10 | HY-12 |

Raw material | Waste tyre, plastic, rubber | Waste tyre, plastic, rubber | Waste tyre, plastic, rubber |

Capacity/day | 5t | 10t | 12t |

Inlet diameter | 1200mm | 1400mm | 1400mm |

working | Batch-tyre | Batch-tyre | Batch-tyre |

Covering area | 200 | 300 | 350 |

Oil yield | 45%-50% | 45%-50% | 45%-50% |

Labor force | 2-3 | 2-3 | 2-3 |

Reactor size | D2200mm*L5000mm | D2600mm*L6600mm | D2800mm*L6600mm |

Noise | ≤85dB | ≤85dB | ≤85dB |

Type ofcooling | Cycle water | Cycle water | Cycle water |

weight | 25t | 30t | 32t |

Running time | 14-16h | 22-24h | 22-24h |

Heating Fuel | Charcoal,wood, oil,gas | Charcoal,wood, oil,gas | Charcoal,wood, oil,gas |

Carbon Dischage | Slagging automatially | Slagging automatially | Slagging automatially |

1. The output product as below

No.1 is pyrolysis oil , this oil can be Used as the heating material and sell it to cement factory, glass factory, ceramic factory, electric power factory, steel making factory, boiler factory, etc. or further refined to diesel by our distillation plant.

No. 3 is plastic diesel , this oil can be applied to diesel engines like ships , trucks , tractors , power generators etc.

2. Your raw material can be PP PE PS ABS ,oily sludge , rubber , scrap tires products etc.

3. Working process Newest pyrolysis of used tyres machines for recycling tire to fuel oil

The following steps broadly describe the tyre pyrolysis process:

1. Pre-treatment: Usually the tire diameter is within 1400mm, then no need pretreat the tires , we can feed the tires into the reactor directly with our auto feeder. if the tire diameter is above 1400mm , then the tires need to be cut into pieces by tire cutter.

2. Feed in system: The pre-treated tyres are loaded into a the auto feeding system where they are fed into the reactor.

3. Heating the tyres in the reactor: After the tyres are fed into the reactor, they are heated (or

‘cooked’) in the absence of oxygen. Each pyrolysis plant will follow its own heating

process. At lower temperatures more liquid products are produced and at higher temperatures

more gaseous products are produced.

4. This produces four products: The end products are char, oil, syngas and scrap steel.

4. Packing and shipping Newest pyrolysis of used tyres machines for recycling tire to fuel oil

1. Packaging Detail:

Needs 2*40HQ+1*40FR for delivery.

All goods are packed with exported standards package to make sure no damage during transportation.

2. Shipment: 25 days after the deposit

5. Our service

1.Huayin’s plants enjoy one-year guarantee, after which, we still offer lifelong technical support for your plant.

2. we will send engineer fo guiding installation , training workers , and trail operation.

3.For any tiny plant problem you cannot solve after one-year guarantee finishes, please feel free to Email or call our salespeople, who will wholeheartedly help you solve your problem.

For problems that cannot be solved via email or phone-call, our engineers may be dispatched to do plant maintenance and debugging until your plant resumes normal operation.

6. About us

With decades’ industrial experience and strong professional business abilities, Huayin R&D Center always dedicates itself to studying and developing advanced Pyrolysis and Distillation Technologies with independent intellectual property rights, providing quality engineering technology service for clients all over the world.

Huayin R&D Center continuously strengthens its exchanges and cooperation with clients, parts suppliers, universities and scientific research institutions and gradually establishes its own standardized R&D system.

Huayin R&D Center participated lots of major projects of domestic and global clients with premium quality of delivery and cooperation process being spoken highly of.

We keep committing ourselves to the development and practice of cutting-edge Pyrolysis and Distillation Technologies, providing constant vitality to the development of this industry.

For more details , welcome send us inquiry.

-

Newly designed waste oil-to-diesel refinery

-

Fully Automatic Plastic Recycling Pyrolysis Diesel Tire Fuel Plant

-

Beston Group does not need to install a small pyrolysis machine for batch pyrolysis of 1-3T/D plastic tire oil sludge

-

Waste Tire Pyrolysis Diesel Plant Machine Manufacturer 5 Ton

-

Automatic control machine for biomass waste plastic tire pyrolysis machine

-

profitable small pyrolysis machine mini pryolysis plant

-

Small batch waste tire/plastic/MSW pyrolysis plant to convert solid waste into fuel oil pyrolysis machine 1-2 tons

-

New Design to Recycle Scrap Tires into Diesel with 50ppm Sulfur

-

Small integrated scrap aluminum and plastic pyrolysis plant provides fuel for machines

-

CE certified 15-50 tons automatic plastic pyrolysis plant continuous waste tire pyrolysis system

Other Products

-

$30000.00 / set

$30000.00 / set -

$35000.00 / set

$35000.00 / set -

$38000.00 / set

$38000.00 / set -

$48000.00 / set

$48000.00 / set -

$40000.00 / set

$40000.00 / set -

$45000.00 / set

$45000.00 / set -

$45000.00 / set

$45000.00 / set -

$40000.00 / set

$40000.00 / set -

$16000.00 / set

$16000.00 / set