Automatic control machine for biomass waste plastic tire pyrolysis machine

-

Supplier: Henan Barui Environmental Protection Equipment Co., Ltd. -

Region: Henan, China -

Contact: Mr Andy Lee -

Price: $10000.00 /set -

Min. Order: 1 set

| raw material: | Wood chips, husks, plastic, tires or other solid waste | Health status: | new |

| product name: | Wood pyrolysis machine | Supply capacity: | 20 sets/season wood pyrolysis equipment |

| Emission Standards: | custom made | Marketing Type: | The latest technology |

| port: | Qingdao, Lianyungang or others | Core components: | pressure vessel |

| Discharge method: | Mechanical unloading machine | Warranty: | 1 year |

| Core component warranty: | 3 years | brand: | Barry |

| Main selling points: | high productivity | working principle: | Pyrolytic Cracking of Hydrocarbon Components |

| Showroom location: | not any | End products: | oil and carbon black |

| Video shipment inspection: | if | Weight (kg): | 25 kg |

| payment terms: | L/C, Western Union, T/T, MoneyGram | Certification: | International Organization for Standardization |

| job type: | batch by batch | Feeding capacity: | 500 kg to 10 tons per batch |

| Applicable industries: | Mechanical repair shops, farms, construction, energy and mining | Package preview: | |

| Mechanical test report: | if | Packaging Details: | Wood pyrolysis equipment standard export packing 40ft HC container |

| Origin: | Henan, China | heating method: | Electric heating or fuel burning |

Name: Automatic control machine for biomass waste plastic tire pyrolysis machine

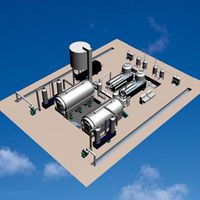

The pyrolysis plant/machine/equipment designed by Henan Bairui has a reasonable equipment structure and process operation method, and can recycle waste tires, plastics, aluminum-plastic composite materials, oil sludge and other petroleum industry products. The final products after recycling are mainly fuel oil, carbon black and other by-products. The details of the pyrolysis equipment are as follows:

| Section 1 Pyrolysis machine model |

| Section 2 Pyrolysis Machine Pictures |

| Section 3 How the Pyrolysis Process Works |

| Section 4 Classification of Pyrolysis Machines |

So far, there is no unified standard for the classification of pyrolysis machines. According to market practice, there are three commonly used classification methods: one is to classify according to the raw materials of the feed pyrolysis machine, the other is to classify according to the installation method of the pyrolysis machine, and the other is to classify the feed and slag discharge according to the feeding method . In addition, for each classification, pyrolysis machines are still different due to construction environment, weather characteristics, policies and regulations, special requirements of customers, etc. The different categories of pyrolysis machines are described in detail below.

4.1 Classification by Raw Material

According to different processing raw materials, pyrolysis machines are divided into tire pyrolysis machines, rubber pyrolysis machines, plastic pyrolysis machines, aluminum-plastic pyrolysis machines, oil sludge pyrolysis machines, oil sand pyrolysis machines, residual oil pyrolysis machines, etc.

4.2 Classification by Installation Type

According to different installation methods, pyrolysis machines are divided into skid-mounted pyrolysis machines and field-installed pyrolysis machines. Since the skid-mounted pyrolysis machines are installed and debugged in our workshop by our professional technicians and reviewed by our inspection engineers, these machines have the advantages of stable performance, short installation time, and simple operation. Therefore, more and more customers prefer our skid mounted pyrolysis machines. In addition, the field-installed pyrolysis machine has the advantage of lower price. If the customer purchases multiple reactors at one time, we can send professional engineers to the customer's factory to guide the installation of multiple reactors at the same time. This can save a lot of equipment costs.

| Section 5 Introduction of commonly used auxiliary equipment |

| Section 6 Equipment Manufacturing Workshop Display |

Henan Barui Environmental Protection Equipment Co., Ltd. is a comprehensive group company integrating technical research and design, equipment design and manufacturing, equipment sales and after-sales service. The factory covers a total area of 23 hectares, and consists of production department, marketing department, technology department, administration department, finance department and two branch companies. We are committed to solid waste recycling projects, renewable oil energy projects and new energy projects. At present, the group serves many large domestic energy companies. International EPC project contracting is the company's new development strategy.

The following is the display of our equipment manufacturing workshop.

-

Newly designed waste oil-to-diesel refinery

-

Fully Automatic Plastic Recycling Pyrolysis Diesel Tire Fuel Plant

-

Beston Group does not need to install a small pyrolysis machine for batch pyrolysis of 1-3T/D plastic tire oil sludge

-

Waste Tire Pyrolysis Diesel Plant Machine Manufacturer 5 Ton

-

profitable small pyrolysis machine mini pryolysis plant

-

Small batch waste tire/plastic/MSW pyrolysis plant to convert solid waste into fuel oil pyrolysis machine 1-2 tons

-

New Design to Recycle Scrap Tires into Diesel with 50ppm Sulfur

-

Small integrated scrap aluminum and plastic pyrolysis plant provides fuel for machines

-

CE certified 15-50 tons automatic plastic pyrolysis plant continuous waste tire pyrolysis system

-

Fully continuous pyrolysis machine 20 tons of plastic waste in fuel oil processing plant

Other Products

-

$50000.00 / set

$50000.00 / set -

$12000.00 / set

$12000.00 / set -

$300000.00 / set

$300000.00 / set -

$12000.00 / set

$12000.00 / set -

$15000.00 / set

$15000.00 / set -

$13000.00 / set

$13000.00 / set -

$28000.00 / set

$28000.00 / set