Plastic pet agglomerator agglomeration agglomerate machine

-

Supplier: Zhangjiagang Sevenstars Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Mabo He -

Price: $6000.00 / 1 - 2 sets

$4000.00 / >=3 sets -

Min. Order: 1 set

Product details

| After-sales Service Provided: | Engineers available to service machinery overseas,Video technical support,Field installation, commissioning and training,Field maintenance and repair service,Online support; | Supply Ability: | 200 Set/Sets per Year; |

| Warranty: | 1 Year; | Material of inner layer: | stainless steel 304; |

| Place of Origin: | Jiangsu China; | Brand Name: | Sevenstars; |

| Showroom Location: | None; | Certification: | CE and ISO9001; |

| Local Service Location: | None; | Automatic water spray system: | By Electromagnetic valve; |

| Marketing Type: | Ordinary Product; | Material Discharging model: | Pneumatic or manual; |

| Applicable Industries: | Manufacturing Plant,agglomerator; | Packaging Detail: | wood pallet packing for Plastic pet agglomerator agglomeration agglomerate machine; |

| Warranty of core components: | 1 Year; | Plastic Type: | PE,PP/PE,PP,PET; |

| pet agglomerate: | pet agglomerate; | Condition: | New; |

| Plastic Agglomeration Machine: | Plastic Agglomeration Machine; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| agglomerator machine: | agglomerator machine; | Payment Terms: | L/C,T/T,Western Union; |

| Core Components: | Bearing,Gearbox,Motor; | Video outgoing-inspection: | Provided; |

| Machinery Test Report: | Provided; | Material Processed: | Pp Pe Film or non-woven fabric; |

| Key Selling Points: | Energy saving; | Voltage: | 380V,50Hz,3Phase or customized; |

| Dimension(L*W*H): | depend on; | Port: | shanghai seaport for Plastic pet agglomerator agglomeration agglomerate machine; |

| Knife material: | 9CrSi; |

Product Description

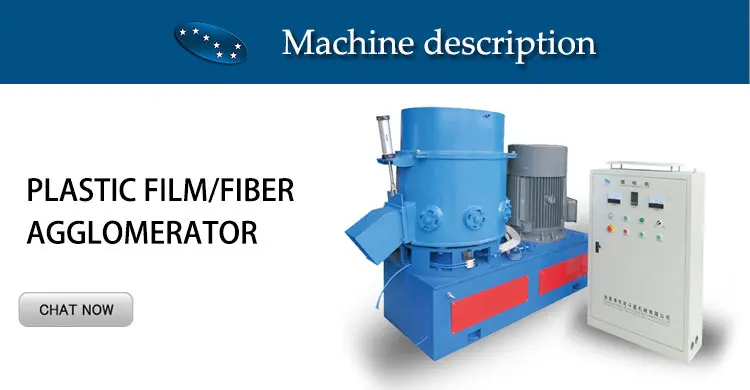

Plastic pet agglomerator agglomeration agglomerate machine

GHX agglomerator can directly make waste plastic films and PET chips and PET/PP fiber and some other textile products into granules. It is suitable to agglomerate the waste products or films made of soft PVC, PET, HDPE, LDPE, PP and other thermo plastics. When the waste plastic is supplied into the chamber of such machine, it will be cut into smaller chips due to the crushing function of the rotating knife and fixed knife. During the crushing processing, the material that soaked up lots heat from the frictional movement of material being crushing and the material will be going to become semi-plasticizing state. The particles will stick with each other due to the function of plasticization. Before it sticks each other completely, the cold water pre-prepared is sprayed into the crushed material. The water will be evaporated off quickly and the surface temperature of crushed material drops down quickly. So the crushed material will become small particles or granules. It is easy to recognize the particles by different size and can be colored by using of color agent being putted into the container during the crushing processing.

The particles can be used for extrusion or injection mould machine directly. Also it can be further pelletized for some advanced requirements.

This machine is qualified with certificate ISO9001:2000 and CE certificate.

Model for Plastic pet agglomerator agglomeration agglomerate machine

MODEL | GHX-100 | GHX-200 | GHX-300 | GHX-500 | GHX-600 | GHX-800 | |||||

Vloumn (L) | 100 | 200 | 300 | 500 | 600 | 800 | |||||

Effective Volumn (L) | 75 | 150 | 225 | 375 | 450 | 600 | |||||

Capacity (kg/h) | 100 | 150 | 200 | 300 | 400 | 550 | |||||

Power (kw) | 37/45 | 45 | 75 | 90 | 110 | 110 | |||||

Material of barrel | Stainless steel | ||||||||||

Recommended products

Contact Me

VIEW MORE

You may like

-

Film Feeder Force Feed Machine Film Feeder For Sale

-

Chinese Brand PE PP ABS Plastic Pelletizing Cutting Machine Plastic Pellet Making Machine Pelletizing Machine

-

Best Quality Low Consumption Styrofoam Recycling Machine

-

High performance melt filter ERF for highly polluting plastic recycling applications

-

Recycled Plastic PET Fiber Plastic Film Pelletizer/Pellet Compactor

-

ABS PP PE single screw stage plastic recycling machine plastic granulator granulator granulator abs granule making machine

-

Pp Pe Plastic Film Recycling/Pelletizing/Pelleting Machine

-

Small Recycled Plastic Pelletizer Recycled Plastic PE PP Granulation Pelletizing Equipment

-

Compact EPS Foam Box Equipment with CE

-

Waste PP PE PVC ABS PET bottle single and double stage plastic recycling granulator price

Other Products

-

$9000.00 / set

$9000.00 / set -

$32000.00 - $40000.00 / set

$32000.00 - $40000.00 / set -

$2100.00 / set

$2100.00 / set -

$20000.00 / set

$20000.00 / set -

$35000.00 - $50000.00 / set

$35000.00 - $50000.00 / set -

$5000.00 / set

$5000.00 / set -

$5000.00 / set

$5000.00 / set -

$2500.00 / set

$2500.00 / set -

$2500.00 - $3000.00 / set

$2500.00 - $3000.00 / set -

$135000.00 - $140000.00 / set

$135000.00 - $140000.00 / set

Related Search

plastic agglomerator machine

agglomerator machine

plastic bag pet bottles date code machine

pet plastic injection stretch blow moulding machine

pellets plastic pet machine

plastic pet bottle wholesale

pet packing strap making machine

small plastic pet plant

recycled plastic pet line

pet preform inject mould machin taiwan suppliers