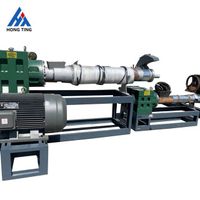

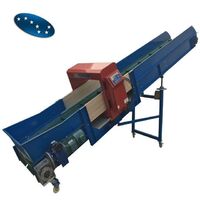

PE PP film agglomerator recycle plastic granules making machine price

-

Supplier: Zhangjiagang Sevenstars Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Mabo He -

Price: $20000.00 /set -

Min. Order: 1 set

| Local Service Location: | None; | Type: | Recycling Granulator; |

| Voltage: | 380V50HZ or optional; | Warranty of core components: | 1 Year; |

| Brand Name: | Sevenstars; | After Warranty Service: | Video technical support,Online support; |

| Place of Origin: | Jiangsu China; | Material: | PE PP; |

| Output (kg/h): | 100 - 500 kg/h; | Core Components: | Bearing,Gearbox; |

| Temperature controller: | Japan "RKC"; | Screw Design: | Single; |

| manufacture experience: | more than 13 years; | Max. Capacity: | 200-1000kg/h; |

| Machinery Test Report: | Provided; | Certification: | ISO CE; |

| Video outgoing-inspection: | Provided; | Dimension(L*W*H): | As model; |

| Supply Ability: | 15 Set/Sets per Quarter; | Contactor: | Schneider; |

| Warranty: | 1 Year; | Packaging Detail: | sea worthy packing for recycle plastic granules making machine price; |

| After-sales Service Provided: | Engineers available to service machinery overseas,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; | Plastic Processed: | PE/PP; |

| frequency inverter: | ABB; | Condition: | New; |

| Showroom Location: | None; | Applicable Industries: | Manufacturing Plant,Recycling Plastic granulator machine; |

| Payment Terms: | L/C,Western Union,T/T; | the material of pelletizing blade: | SKD-11(D2); |

| Main motor: | Siemens; | Port: | shanghai; |

| material processed: | Waste pp and pe film; | Marketing Type: | Ordinary Product; |

| Weight: | 7000kg; |

The pellets

Specifications

PE/PP Film Double Stage Plastic Pellets Price

1.Capacity:200kg/h-500kg/h

2.Type:water-ring and stand pelletizer

3.ISO,CE

pp pe film pelletizing line/ Plastic film granulator

Usage:

This water-cooling single screw plastic pellet making machine is double stage plastic regenerative pelletizer, which is suitable for many kinds plastic waste materials recycling and making pellet, such as PP, HDPE, LDPE, LLDPE Film and clean woven/nonwoven bag materials, etc.

The film can be pressed in compressor and then be pelleted.And also has very developed design, makes sure this machine has a long working life and economical efficiency in using.

Characteristic:

1. Screw and barrel are made of 38CrMoAlA, inlet mouth treated with special alloy: very strong and long life.

2. Easy operation: it has automatic constant temperature control and stable performance. After adjusting well, 1 or 2 workers are enough to run this machine, to feed the materials and change pellet receiver.

3. Low cost in using after redesign: now this kind machine is more economic in electric power source and also water. In the long working life of this machine, it can save many sources in energy!

4. High output, long operating life and lower noise: it’s the ideal waste plastics regenerative pelletizer machine for nowadays.

Main parameter SJ series Single-stage/Double-stage PEPP plastic film pelletizing line/granulating machine:

SJ series single screw pe pp plastic film granulator machine | ||||||||||||

Model | SJ-65 | SJ-80 | SJ-100 | SJ-120 | SJ-150 | SJ-200 | ||||||

Screw Dia. | 65 | 80 | 100 | 120 | 150 | 200 | ||||||

L/D | 28-30 | 28-30 | 28-30 | 28-30 | 28-30 | 28-30 | ||||||

Capacity | 60-80kg/h | 80-100kg/h | 150kg/h | 300kg/h | 400kg/h | 500kg/h | ||||||

SJ series double-stage pe pp plasic film granulator machine | ||||||||||||

Model | SJ-100/100 | SJ-120/120 | SJ-150/150 | SJ-200/200 | ||||||||

Screw Dia. | 100 | 120 | 150 | 200 | ||||||||

L/D | 28-30 10-15 | 28-30 10-15 | 28-30 10-15 | 28-30 10-15 | ||||||||

Capacity | 120-180kg/h | 220-300kg/h | 300-400kg/h | 500-600kg/h | ||||||||

Main parameter ZL series Single-stage/Double-stage PEPP film Compactor-granulating line/granules making machine

SJ series single stage pe pp film compactor-granulator machine(with agglomerator) | ||||||||||

Model | ZL-85 | ZL-100 | ZL-130 | ZL-160 | ZL-180 | |||||

Screw Dia. (mm) | 85 | 100 | 130 | 160 | 180 | |||||

L/D Ratio | 25-42 | 25-42 | 25-33 | 25-33 | 25-33 | |||||

Output (kg/hr) | 120-180 | 250-350 | 400-500 | 550-700 | 800-1000 | |||||

SJ series double- stage pe pp film compactor-granulator machine(with agglomerator) | ||||||||||

Model | ZL-85/85 | ZL-100/100 | ZL-130/130 | ZL-160/160 | ZL-180/180 | |||||

Screw Dia. (mm) | 85 | 100 | 130 | 160 | 180 | |||||

L/D Ratio | 25-42 | 25-42 | 25-33 | 25-33 | 25-33 | |||||

Output (kg/hr) | 120-180 | 250-350 | 250-350 | 250-350 | 250-350 | |||||

-

Plastic granulation recycling line PE PP film granulator plastic film granulator granulator

-

Cheap price PP PE granulation plastic granulator granulator

-

Hot Selling Plastic Granule Manufacturing Process

-

HDPE PP ABS PE Recycled Plastic Pelletizer Plastic Pelletizer

-

Plastic granulator Pe water ring eager cutting granulator plastic granulator

-

TL100 waste plastic film granulation concentrator granulation recycling

-

Pp Pe plastic woven bag granulation production line granulation system

-

Factory direct sales waste granulation line plastic recycling machine granulator

-

ps recycled waste granulator extrusion LDPE granulator production line

-

SDHT plastic granulator recycling machine extruder granulator factory direct sales hot sale

Other Products

-

$9000.00 / set

$9000.00 / set -

$32000.00 - $40000.00 / set

$32000.00 - $40000.00 / set -

$2100.00 / set

$2100.00 / set -

$4000.00 - $6000.00 / set

$4000.00 - $6000.00 / set -

$35000.00 - $50000.00 / set

$35000.00 - $50000.00 / set -

$5000.00 / set

$5000.00 / set -

$5000.00 / set

$5000.00 / set -

$2500.00 / set

$2500.00 / set -

$2500.00 - $3000.00 / set

$2500.00 - $3000.00 / set -

$135000.00 - $140000.00 / set

$135000.00 - $140000.00 / set