Recycled Plastic PET Fiber Plastic Film Pelletizer/Pellet Compactor

-

Supplier: Zhangjiagang Camel Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Jerry xia -

Price: $3500.00 /set -

Min. Order: 1 set

Product details

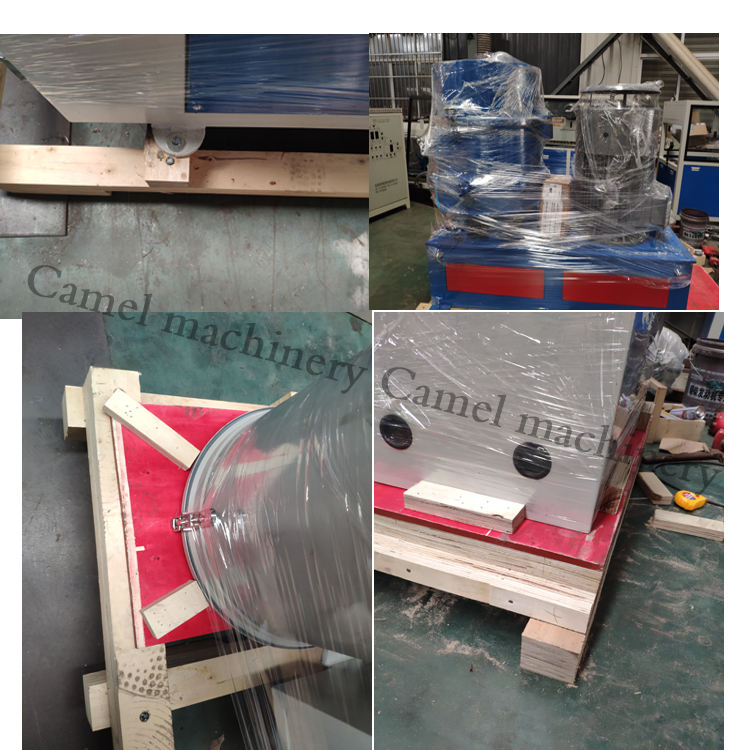

| Mechanical test report: | if | Packaging Details: | Standard wood packaging covered with plastic film |

| After-sales service provided: | Video Technical Support | brand: | camel |

| Certification: | CE ISO TUV | Warranty: | 1 year |

| Showroom location: | France, Peru, Indonesia, Pakistan, Mexico, Chile, Colombia, Romania, South Africa, Kazakhstan, Ukraine | port: | Shanghai Port |

| Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| engine: | Siemens, Bader | Input material: | waste film plastic |

| Applicable industries: | Manufacturing Plant, Pellet Pellet Manufacturing, Pelletizer, Granulator, Recycling Machine | color: | white, blue, customized |

| After warranty service: | On-site maintenance and repair services | usage: | lumps of plastic trash |

| Contactor: | Schneider, Siemens | Core component warranty: | 1 year |

| Dimensions (L*W*H): | 1700*800*1500mm | application: | recycling granulator |

| Main selling points: | high productivity | Video shipment inspection: | if |

| Health status: | new | Plastic Type: | Polyethylene, Polypropylene/Polyethylene, Polypropylene |

| output: | 100-800kg/hour | Supply capacity: | 40 sets per month |

| Origin: | Jiangsu, China | Weight (kg): | 1000 |

| Package preview: | Marketing Type: | normal product |

Product Description

Plastic film coagulant/thickener

brief introduction:

The granulator can directly recycle waste plastic film and other products with a wall thickness less than 2mm into granules. The raw material can be soft PVC, Hdpe, Ldpe, Pp, Bopp film/bag, woven bag and other thermoplastics.work process:

When the waste plastic enters the cavity of the machine, the waste plastic is cut into smaller pieces due to the crushing action of the rotary knife and the fixed knife. During the crushing process, the material absorbs a large amount of heat due to frictional movement during the crushing process, and the material will become semi-plasticized. Due to plasticization, the particles stick to each other. Spray pre-prepared cold water into the crushed material before it sticks together completely. Moisture will evaporate quickly, and the surface temperature of the crushed material will drop rapidly. So the crushed material will become small particles or granules.

advantage:

Particles of different sizes are easily identifiable and can be colored with colorants placed in containers during the crushing process. Pellets can be used directly in extrusion or injection molding machines. It can also be further granulated to meet some advanced requirements.

The machine has passed the ISO9001:2000 certificate.

detailed drawing

Rotary and fixed blades.

(additional blades available)

engine

(motor brand customization)

Electrical control cabinet

Technical Parameters

Model | GHC1000 | GHC800 | GHC500 | GHC300 | GHC200 | GHC100 |

Tank volume (liter) | 1000 | 800 | 500 | 300 | 200 | 100 |

Working volume (liter) | 750 | 600 | 375 | 200 | 150 | 75 |

Production capacity (kg/hour) | 600~800 | 400~650 | 350~500 | 200~350 | 150~250 | 100~150 |

Motor power (Kw) | 132 | 110 | Post-90s | 75 | 55 | 37 |

Rotating blade speed (r/min) | 700 | 750 | 750 | 900 | 800 | 800 |

Number of rotary blades (pieces) | 4 | 4 | 4 | 2 | 2 | 2 |

Number of fixed blades (pcs) | 8 | 8 | 8 | 8 | 6 | 6 |

discharge model | Manual / Auto | Manual / Auto | Manual / Auto | Manual / Auto | Manual / Auto | Manual / Auto |

water spray | Manual / Auto | Manual / Auto | Manual / Auto | Manual / Auto | Manual / Auto | Manual / Auto |

Machine size Length x width x height (mm) | 2680×1815 ×2400 | 2170×1510 ×2140 | 2100×1510 ×2145 | 2100×1495 ×1945 | 1900×1160 ×1800 | 1900×650 ×1310 |

machine weight ( Kilogram) | 3500 | 2800 | 2500 | 2000 | 1800 | 1200 |

packing and loading

VIEW MORE

You may like

-

Film Feeder Force Feed Machine Film Feeder For Sale

-

Chinese Brand PE PP ABS Plastic Pelletizing Cutting Machine Plastic Pellet Making Machine Pelletizing Machine

-

Best Quality Low Consumption Styrofoam Recycling Machine

-

High performance melt filter ERF for highly polluting plastic recycling applications

-

ABS PP PE single screw stage plastic recycling machine plastic granulator granulator granulator abs granule making machine

-

Pp Pe Plastic Film Recycling/Pelletizing/Pelleting Machine

-

Small Recycled Plastic Pelletizer Recycled Plastic PE PP Granulation Pelletizing Equipment

-

Compact EPS Foam Box Equipment with CE

-

Waste PP PE PVC ABS PET bottle single and double stage plastic recycling granulator price

-

High-efficiency PP PE plastic film agglomerator / agglomerator / waste plastic agglomerator

Other Products

-

$6500.00 - $6900.00 / set

$6500.00 - $6900.00 / set -

$3000.00 / set

$3000.00 / set -

$2450.00 - $2500.00 / set

$2450.00 - $2500.00 / set -

$4900.00 - $5000.00 / set

$4900.00 - $5000.00 / set -

$3366.00 / set

$3366.00 / set -

$29800.00 / set

$29800.00 / set -

$2000.00 / set

$2000.00 / set -

$38000.00 / set

$38000.00 / set -

$3400.00 / set

$3400.00 / set -

$9800.00 / set

$9800.00 / set