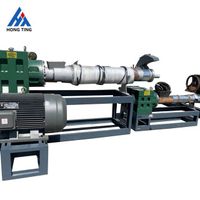

Waste Plastic Film Agglomerator Densifier Machine For sale

-

Supplier: Zhangjiagang Camel Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Jerry xia -

Price: $2500.00 / 1 - 1 sets

$2450.00 / >=2 sets -

Min. Order: 1 set

| Function: | Make Recycle Plastic Granules; | Certification: | CE ISO9001; |

| Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Manufacturing Plant,Machinery Repair Shops,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company; | Color: | Customer Choice; |

| Dimension(L*W*H): | 1000*120*150MM; | Raw material: | PP PE Film; |

| Type: | Recycling Granulator; | Port: | shanghai; |

| Keywords: | plastic agglomerator machine; | Core Components: | PLC,Engine,Bearing,Gearbox,Motor,Pressure vessel,Gear,Pump; |

| After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; | Material: | PP/PE; |

| Screw Design: | Other; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; | Place of Origin: | Jiangsu, China; |

| Heating Method: | By self friction; | Showroom Location: | Italy,Viet Nam,India,Russia,Kenya,Romania,Bangladesh,Ukraine,Uzbekistan; |

| Warranty of core components: | 1 Year; | Output (kg/h): | 100 - 700 kg/h; |

| Material Processed: | Waste PP PE ABS Plastic; | Machinery Test Report: | Provided; |

| Rotary blades: | 2-4 pcs; | Power (kW): | 65; |

| Warranty: | 1 Year; | Discharge Metho: | Manually or Pneumatic; |

| Voltage: | 380V 50HZ; | Application: | Granules Production; |

| Marketing Type: | New Product 2020; | Condition: | New; |

| Weight: | 1000kg; | Supply Ability: | 100 Sets per Month; |

| Local Service Location: | Italy,Germany,Viet Nam,Pakistan,Spain,Malaysia,Australia,Argentina,Colombia,Sri Lanka,Tajikistan; | Video outgoing-inspection: | Provided; |

| Brand Name: | Camel; | Packaging Detail: | Standard shipping package; |

| Plastic Processed: | PE/PP; |

Model | GHC1000 | GHC800 | GHC500 | GHC300 | GHC200 | GHC100 |

Tank volume (Liter) | 1000 | 800 | 500 | 300 | 200 | 100 |

Working volume (Liter) | 750 | 600 | 375 | 200 | 150 | 75 |

Capacity( Kg/h) | 600~800 | 400~650 | 350~500 | 200~350 | 150~250 | 100~150 |

Motor power (Kw) | 132 | 110 | 90 | 75 | 55 | 37 |

Rotating blades speed (r/min) | 700 | 750 | 750 | 900 | 800 | 800 |

Rotating blades quantity (pcs) | 4 | 4 | 4 | 2 | 2 | 2 |

Stationary blades quantity(pcs) | 8 | 8 | 8 | 8 | 6 | 6 |

Discharging model | Manual / Auto | Manual / Auto | Manual / Auto | Manual / Auto | Manual / Auto | Manual / Auto |

Water spraying way | Manual / Auto | Manual / Auto | Manual / Auto | Manual / Auto | Manual / Auto | Manual / Auto |

Machine dimension L×W×H (mm) | 2680×1815 ×2400 | 2170×1510 ×2140 | 2100×1510 ×2145 | 2100×1495 ×1945 | 1900×1160 ×1800 | 1900×650 ×1310 |

Machine weight ( Kg) | 3500 | 2800 | 2500 | 2000 | 1800 | 1200 |

PVC pipe production line

WPC profile extrusion line

PVC profile making machine

PE pipe extrusion line

Plastic washing line

Plastic granulating line

Plastic Crusher

Shredder

Plastic milling machine

Q1:What about the payment terms?

A1:Always 30% down payment as deposit,70% balance pay before shipping.

Q2:What about the payment way?

A2:TT,L/C at sight or Alibaba trade assurance.

Q3:If you will send engineer coming to our factory to install and test the machines?

A3:Yes,Every set of machine we will send professional engineer to your factory and help installation and test the machines for you.

Q4:If you have CE,SGS,ISO certificate?

A4:Yes,except these,if you also need other certificates,we also can help to apply.

Q5:If we buy your machines, can you offer us wear-out spare pats?

A5:Yes,We provide our high quality machine 1 years’ guarantee,and we will also offer you 1 years wear-out spare parts for free. Once your machines broken or doesn't work within 1 years and you can't solve it, firstly, we will try to help you to find problems from your words description by phone or other communication tools. Secondly, if the phone solutions still not work, our engineers will go to your factory to solve it. Meanwhile, they will teach you the related experiences for fixing.

Q6:What is the voltage?

·A6 380V 50hz 3 phase or any other voltage according to client's requirement.

Q7:If you support Alibaba trade assurance pay?

A7:Yes.100% support.

-

Plastic granulation recycling line PE PP film granulator plastic film granulator granulator

-

Cheap price PP PE granulation plastic granulator granulator

-

Hot Selling Plastic Granule Manufacturing Process

-

HDPE PP ABS PE Recycled Plastic Pelletizer Plastic Pelletizer

-

Plastic granulator Pe water ring eager cutting granulator plastic granulator

-

TL100 waste plastic film granulation concentrator granulation recycling

-

Pp Pe plastic woven bag granulation production line granulation system

-

Factory direct sales waste granulation line plastic recycling machine granulator

-

ps recycled waste granulator extrusion LDPE granulator production line

-

SDHT plastic granulator recycling machine extruder granulator factory direct sales hot sale

Other Products

-

$6500.00 - $6900.00 / set

$6500.00 - $6900.00 / set -

$3500.00 / set

$3500.00 / set -

$3000.00 / set

$3000.00 / set -

$4900.00 - $5000.00 / set

$4900.00 - $5000.00 / set -

$3366.00 / set

$3366.00 / set -

$29800.00 / set

$29800.00 / set -

$2000.00 / set

$2000.00 / set -

$38000.00 / set

$38000.00 / set -

$3400.00 / set

$3400.00 / set -

$9800.00 / set

$9800.00 / set