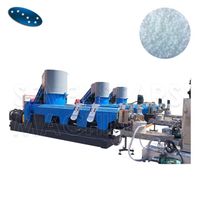

Best Quality Low Consumption Styrofoam Recycling Machine

-

Supplier: Henan Kellen Machinery Equipment Co., Ltd. -

Region: Henan, China -

Contact: Ms Darcy chen -

Price: $1580.00 /set -

Min. Order: 1 set

Product details

| Package preview: | Voltage: | 220V/380V | |

| Health status: | new | aspect: | 1500*1500*1100mm |

| Key words: | Melt compactor | Weight (kg): | 410 |

| weight: | 410 kg | Supply capacity: | 300 sets per month |

| Marketing Type: | normal product | Video outbound inspection: | if |

| Energy supply: | engine | Warranty: | 1 year |

| capacity: | 130 kg/h | Main selling points: | energy saving |

| Origin: | China | product name: | Expanded polystyrene foam hot melt machine |

| Applicable industries: | building materials store, other | Showroom location: | not any |

| Core component warranty: | 2 years | port: | Qingdao, Tianjin, Shanghai, Guangzhou, Dalian, etc. |

| type: | vertical | Packaging Details: | Expanded polystyrene foam hot melt machine is packed in standard export wooden case |

| Model: | KLVM-130 | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| strength: | 7.5kW/15kW | Mechanical test report: | not available |

| Core components: | engine | Plastic Type: | polyurethane, polystyrene, polystyrene |

Product Description

efficient energyEPS melting machine

The foam breaking expander is also a kind of foam making machine. The foam expansion unit and the foam expansion unit are composed of a foam breaker and a foam maker. The function of the foam crusher is to crush waste foam, which can crush white polluting garbage such as foam snack boxes, cake boxes, foam packaging materials, and insulation materials. materials and foams, and the omentum.

The foam machine is to heat and plasticize the waste foam particles crushed by the foam crusher through the screw, and extrude them into clusters, which is convenient for transportation and sales.

The foam machine is to heat and plasticize the waste foam particles crushed by the foam crusher through the screw, and extrude them into clusters, which is convenient for transportation and sales.

The foam box hot melt machine adopts a double-shaft crushing knife, which can effectively crush expanded polystyreneBreaks down material into smaller pieces and onto the screen. Materials that cannot enter the screen are further crushed, fall into the screen, and then enter the main machine. The crushed materials are transported to the conical cylinder and circular cylinder through the high-speed rotation of the screw, and the mica heater heats the material. Make the material melt, and then continue to convey the molten material. After the square mold is formed, the material begins to cool and the square recyclate is extruded from the mold. According to the required length, it is automatically cut by a cutting machine to complete the production process.

product display

Specification

vertical | ||||

Model | KLVM-130 | KLVD-130 | ||

type | engine | diesel engine | ||

Voltage | 220V/380V | / | ||

strength | 7.5kW/15kW | / | ||

aspect | 1500*1500*1100mm | 1700*1600*1200 mm | ||

capacity | 130 kg/h | 130 kg/h | ||

weight | 410 kg | 580 kg | ||

We have many models, please send me an inquiry or add my WhatsApp (+0086 15036175334) I will recommend the most suitable machine for you~ | ||||

horizontal | ||||

Model | KLHM-150 | KLHD-150 | ||

type | engine | diesel engine | ||

Voltage | 220V/380V | / | ||

strength | 18.5 kW | / | ||

aspect | 1500*1700*1400mm | 1600*1800*1500mm | ||

capacity | 150 kg/h | 150 kg/h | ||

weight | 650 kg | 700 kg | ||

We have many models, please send me an inquiry or add my WhatsApp (+0086 15036175334) I will recommend the most suitable machine for you~ | ||||

We also have many other models of machines, please feel free to contact me.

detailed image

The host of the foam briquetting machine is an extrusion machine, which is composed of an extrusion system, a transmission system and a heating system.

Extrusion system The extrusion system includes screw, barrel, hopper and die. The plastic is plasticized into a uniform melt through the extrusion system, and under the pressure established in the process, the screw is continuously extruded by the machine head.

(1) Screw: It is the main part of the extruder, which is directly related to the application range and productivity of the extruder. It is made of high-strength, corrosion-resistant alloy steel. (2) Cylinder: It is a metal cylinder, generally made of steel pipe with heat resistance, high compressive strength, wear resistance and corrosion resistance. The barrel cooperates with the screw to realize the crushing, softening, melting, plasticizing, exhausting and compacting of the plastic, and continuously and evenly transport the rubber to the molding system. Generally, the length of the barrel is 15 to 30 times its diameter, and the principle is that the plasticized foam can be fully heated and fully plasticized. (3) Hopper: There is a cutting device at the bottom of the hopper, which is used to adjust and cut off the material flow. The side of the hopper is equipped with an observation hole and a calibration metering device.

Applications

EPS melting machine scope of application:

Scope of application of the OrdinanceEPS meltingThis machine includes the crushing of EPS, XPS, EPP, EPE, PU and other materials, and is widely used in waste foam scraps, packaging foam, disposable lunch boxes, polyurethane insulation boards, extruded boards, lost foam and rock wool boards, and foam boxes. , heat insulation board, KT board, heating materials and other recycling industries.

VIEW MORE

You may like

-

Film Feeder Force Feed Machine Film Feeder For Sale

-

Chinese Brand PE PP ABS Plastic Pelletizing Cutting Machine Plastic Pellet Making Machine Pelletizing Machine

-

High performance melt filter ERF for highly polluting plastic recycling applications

-

Recycled Plastic PET Fiber Plastic Film Pelletizer/Pellet Compactor

-

ABS PP PE single screw stage plastic recycling machine plastic granulator granulator granulator abs granule making machine

-

Pp Pe Plastic Film Recycling/Pelletizing/Pelleting Machine

-

Small Recycled Plastic Pelletizer Recycled Plastic PE PP Granulation Pelletizing Equipment

-

Compact EPS Foam Box Equipment with CE

-

Waste PP PE PVC ABS PET bottle single and double stage plastic recycling granulator price

-

High-efficiency PP PE plastic film agglomerator / agglomerator / waste plastic agglomerator

Other Products

-

-

$500.00 / set

$500.00 / set -

$405.00 / set

$405.00 / set -

$170.00 - $220.00 / set

$170.00 - $220.00 / set -

$1500.00 / set

$1500.00 / set -

$890.00 / set

$890.00 / set -

$1400.00 - $1430.00 / set

$1400.00 - $1430.00 / set -

$800.00 - $1000.00 / set

$800.00 - $1000.00 / set -

$1500.00 / set

$1500.00 / set -

$320.00 / set

$320.00 / set

Related Search

low cost plastic recycling machine suppliers

styrofoam recycle machine

high quality tyre recycle machine

best tyre recycl machin suppliers

high quality textile waste recycling machine

best quality color roof tile machine

copper recycling machine

asphalt recycling machine

tire recycling machine

tire recycling machine prices