Good price Plastic recycling machine waste PE PP film bag recycle washing line

-

Supplier: Jiangsu Fangsheng Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Sion chen -

Price: $50000.00 /set -

Min. Order: 1 set

Product details

| CE: | YES; | Brand Name: | fangsheng; |

| Warranty: | 1 year; | Warranty of core components: | 1 Year; |

| ISO9001: | YES; | Delivery time: | 2-3months; |

| Local Service Location: | None; | Material Processed: | Film,bags; |

| Certification: | CE ISO9001; | Application: | film recycling line; |

| Plastic Type: | PE,PP,PP/PE; | Max.Production Capacity (kg/h): | 1000; |

| Condition: | New; | Dimension(L*W*H): | 20000/3600/2800 MM; |

| Marketing Type: | New Product 2020; | Production Capacity (kg/h): | 300 - 6000; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Blades For Crusher: | SKD-II; |

| Applicable Industries: | Manufacturing Plant,Energy & Mining,plastic recycle; | Showroom Location: | None; |

| Equipment List: | Dewatering Machine,Horizontal dehydrator; | Package Preview: | ; |

| Payment Terms: | L/C,Western Union,T/T; | Place of Origin: | Jiangsu China; |

| Core Components: | PLC,Engine,Bearing,Motor,Gear,Pump; | Weight (T): | 50; |

| Control: | PLC; | Power (kW): | 120-300kw; |

| Machine Type: | PP PE Film Washing Line; | Voltage: | 380V 50HZ; |

| Type: | polyethylene film recycling; | Automatic Grade: | Automatic; |

| Machinery Test Report: | Provided; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Video outgoing-inspection: | Provided; | Key Selling Points: | Automatic; |

| Supply Ability: | 100 Set/Sets per Year polyethylene film recycling machine; |

Product Overview

Good price Plastic recycling machine waste PE PP film bag recycle washing line

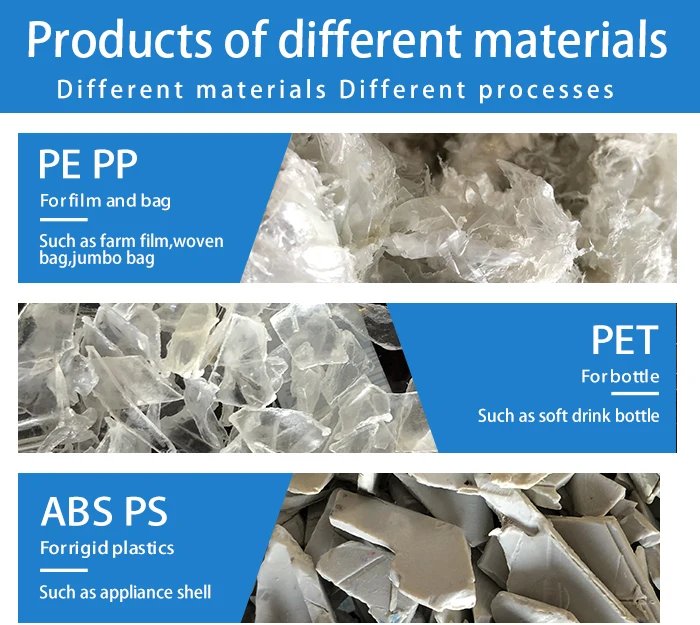

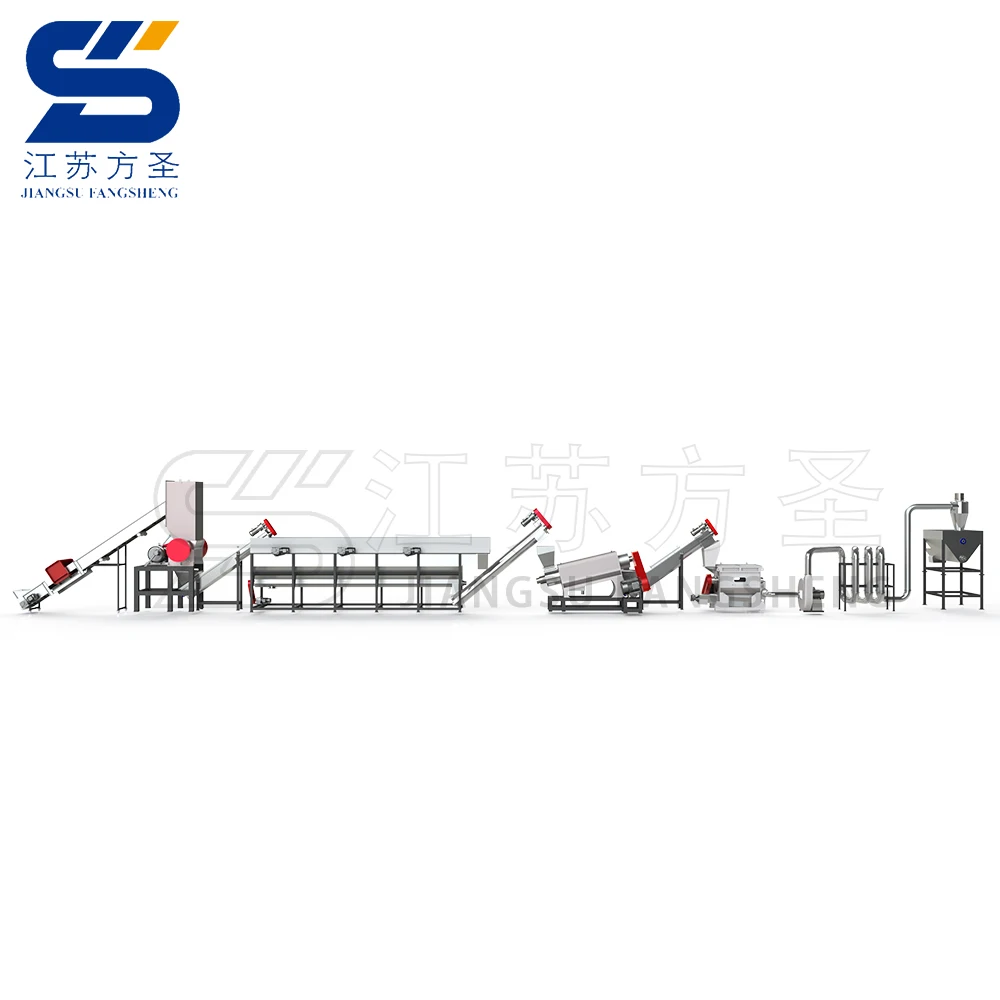

Plastic (Film/woven bag/fiber/rope) Washing Line has smart modular design aiming at agricultural film, industrial packaging film, bag waste recycling. It is including sorting, size reduction, metal removing, cold and hot washing, high efficiency friction washing and drying modular. Which can remove most of contaminants such as ferrous and nonferrous metals contaminants efficiently. Moreover, the solution can be provided with all water treatment, processing of sludge, paper stick, labels and etc.

Detail Specification

Crusher

●rotor with balance treatment for stability and low noise

●rotor with heat treatment for long lifespan

●rotor with heat treatment for long lifespan

●wet crushing with water, which can cool the blades and wash the plastic in advance

●can also choose shredder before the crusher

●special rotor structure design for different plastics like bottles or film

●blades made of special material, with high hardness

●easy operation to change blades or screen mesh

●high capacity with stability

Floating washer

●rinse the pieces of flakes or scraps in water

●can use hot type washer to add chemical for washing

●upper roller be inverter controlled

●all tank made of SUS304 or even 316L if needed

●bottom screw can process sludge

Screw conveyor

●Conveying plastic materials

●Made of SUS 304

●With water input to rub and wash the plastic scraps

●with 6mm vane thickness

●made by two layers, dewatering screw type

●hard tooth gear box which ensures long lifespan

●special bearing structure to protect bearing from possible water leakage

Friction Washing

●Friction to clean the materials mechanically

●rotor made of strong&thick material, surface treatment with alloy

●rotor with balance treatment for stability

●rotor with heat treatment for long lifespan

●The bearing is externally connected with water cooling sleeve, which can effectively cool the bearing.

Dewatering Machine

●Drying materials by centrifugal force

●rotor made of strong&thick material, surface treatment with alloy

●rotor with balance treatment for stability

●rotor with heat treatment for long lifespan

●The bearing is externally connected with water cooling sleeve, which can effectively cool the bearing.

●rotor with heat treatment for long lifespan

●The bearing is externally connected with water cooling sleeve, which can effectively cool the bearing.

Squeezer& Squeezing granulation machine

●Drying materials by squeezing

●Made of 38CrMoAlA with high hardness

●guarantee final low moisture

●guarantee final low moisture

Technology Parameter

Name | Motor power (kw) | Dimension (mm) | Water consumption (T/H) | Stainless steel standard (mm) | Electric standard |

Belt conveyer | 2.2 | 3500*900*3000 | - | - | According to customers standard |

Label Scraping Machine | 11 | 2600*1200*1800 | 0.6-1.0 | 3-5 | |

Manual separating Machine | 2.2 | 6000*800*1200 | - | - | |

Metal detectory | 0.4 | 2200*1200*1500 | - | 3-5 | |

Belt conveyer | 2.2 | 3500*900*3000 | - | - | |

Crusher | 37 | 2200*2200*3000 | 0.6-1.0 | - | |

Screw conveyer | 3 | 2800*800*2600 | - | 3-5 | |

High speed friction washer | 30 | 3200*1400*2000 | 1-2 | 3-5 | |

screw conveyer | 3 | 2800*800*2600 | - | 3-5 | |

floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

screw conveyer | 3 | 2800*800*2600 | - | 3-5 | |

Steam Washer | 7.5 | 1800*1800*2700 | 0.5-1.5 | 3-5 | |

Screw Conveyer | 3 | 2800*800*2600 | - | 3-5 | |

Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

Screw conveyer | 3 | 2800*800*2600 | - | 3-5 | |

dewatering machine | 5.5 | 800*2200*2200 | - | 5 | |

drying system | 11 | 3500*2200*2200 | - | 3-5 | |

Label separater | 4 | 800*1100*3800 | - | - | |

storage hopper | - | 1500*1500*3800 | - | - | |

electric elements | - | 2000*450*1780 |

Main Parameters

Successful Project

OUR COMPANY

FAQ

1.Your company is a transactional company or an industrial manufacture factory?

We are an industrial manufacture factory which locates in Zhangjiagang city.

2.All of your products are made by your self or compacted via purchasing the others?

We have independent technical team who focus on making machines, all the products are made by our technical team.

3.What is the ability of your factory?

About 80 lines per year.

4.Do you have any other services about your products?

We have a lot of experience on making projects and specifications for our clients, also we have a fixed service system.

5.How do you make the quotation for clients?

The price depends on quality and performance but the clients should be satisfied first.

We are an industrial manufacture factory which locates in Zhangjiagang city.

2.All of your products are made by your self or compacted via purchasing the others?

We have independent technical team who focus on making machines, all the products are made by our technical team.

3.What is the ability of your factory?

About 80 lines per year.

4.Do you have any other services about your products?

We have a lot of experience on making projects and specifications for our clients, also we have a fixed service system.

5.How do you make the quotation for clients?

The price depends on quality and performance but the clients should be satisfied first.

VIEW MORE

You may like

-

Sevenstars PET bottle recycling machine/plastic cleaning machine/plastic recycling equipment

-

Best Price Waste Plastic PP PE ABS PS PET Recycling Pelletizing Machine Recycling Plastic Pelletizing Machine Production Line

-

pp woven bag recycling cleaning line plastic cleaning recycling machine garbage recycling plant

-

Waste plastic recycling line PET bottle flakes crushing and cleaning production line

-

Waste recycling machine for plastic bottles/pp pe recycling line for washing hdpe flakes

-

Plastic Recycling Machine Cost / Plastic Recycling Plant / Recycling Plastic Pelletizer Price

-

PET bottle recycling machine/plastic washing machine/plastic recycling plant

-

Large capacity 2000kg/hr PET bottle recycling line

-

PP PE/PET Flake Washing Machine Floating Tank Floating Washing Machine for Plastic Recycling Washing Line

-

Polyester Fiber Recycled Making Machine/Waste PET plastic extruder machine/plant

Other Products

-

$80000.00 / set

$80000.00 / set -

$50000.00 / set

$50000.00 / set

Related Search

good price electric strapping machine

plastic recycling extruding line

pe pp film pelletizers

Recycle Washing Line

waste plastic recycling machine

pp lldpe ldpe hdpe pe plastic recycling line

plastic recycling machine price

plastic recycling machine

machine for pe plastic

pyrolysis waste plastic recycling machinery