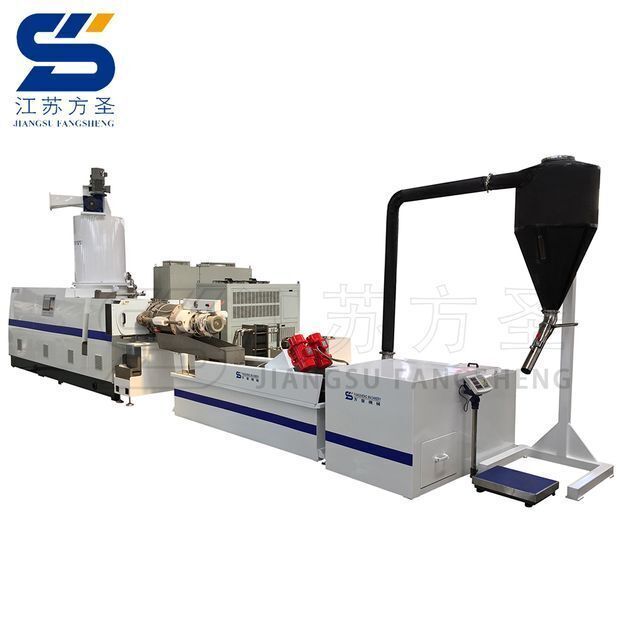

Waste plastic recycling granulating plant plastic pp pe recycling pelletizer

-

Supplier: Jiangsu Fangsheng Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Sion chen -

Price: $50000.00 /set -

Min. Order: 1 set

Product details

| After-sales Service Provided: | Engineers available to service machinery overseas,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; | Packaging Detail: | standard wood case and PE stretch wrapping film for Waste plastic pellets recycling granulating plant plastic pp pe recycling pelletizer; |

| Screw diameter (mm): | Other,Other; | Showroom Location: | None; |

| Twin Screw Type: | Counter-rotating conical Twin-screw,Counter-rotating conical Twin-screw; | Marketing Type: | New Product 2020; |

| Screw material: | 38CrMoAl; | Warranty: | 1 Year; |

| Warranty of core components: | 1 Year; | Output (kg/h): | 300 - 1000 kg/h; |

| Place of Origin: | Jiangsu China; | Motor: | SIEMENS; |

| Payment Terms: | L/C,Western Union,T/T; | Material: | PP/PE; |

| Material Processed: | PE Film,PP Woven Bags,EPS Foam; | Screw L/D Ratio: | Other,Other; |

| Contactor: | SIEMENTS or customized; | Brand Name: | Fangsheng; |

| Port: | Shanghai for Waste plastic pellets recycling granulating plant; | Video outgoing-inspection: | Provided; |

| Inverter: | TECO; | Screw Design: | Double; |

| Keywords: | Waste plastic pellets recycling granulating plant; | After Warranty Service: | Video technical support,Online support,Spare parts; |

| Machinery Test Report: | Provided; | Plastic Processed: | HDPE,HDPE/PP,PE/PP,ABS/PP,PP,FRPP/PVC,PVC,LDPE,ABS,PET,EVA,PC,EPS; |

| Manufacturer: | FANGSHENG Machinery; | Condition: | New; |

| Final product: | PP PE Pelletes; | Core Components: | PLC,Bearing,Motor,Pressure vessel; |

| Supply Ability: | 100 Set/Sets per Year Waste plastic pellets recycling granulating plant; | Weight: | 20t; |

| Applicable Industries: | Manufacturing Plant; | Local Service Location: | None; |

| Screw Speed (rpm): | 30 - 120 rpm; | Dimension(L*W*H): | Different; |

| Certification: | CE ISO9001; | Voltage: | 380V 50HZ or customized; |

| Type: | Recycling Granulator; | Power (kW): | 80-150KW; |

Product Overview

Waste plastic recycling granulating plant plastic pp pe recycling pelletizer

This series compacting pelletizing line, it is a recycling machine designed for low density plastic articles. It could provide the excellent re-pelletizing and recycling solution for film, raffia, filament, woven bag and nonwoven fabric post soft or rigid plastic.

Our pellet making machine has a wide application in PE, PP, CPP, BOPP, PS, PPS, EPS, ABS, PA, PLA, PET waste plastic materials recycling field.

Detail Specification

Compactor

●The rotatory blades of compactor will cut up incoming scraps.

● Frictional heating which caused by high speed rotatory blades and stationary blades will heat and let scraps shrinking just below their agglomerating point.

● Optimal designed guide structure compacts the material and directs it into extruder screw.

Extruder Machine

●A specialized single screw extruder applied to gently melt the pre-compacted material.

●The plastic scraps will be well melted, plasticized in the extruder.

●With double-zone vacuum degassing system, volatiles such as low molecular and moisture will be removed efficiency, especially suitable to heavy printed film and material with some water content.

Technology Parameter

FS series single-stage pe pp film compactor-granulator machine(with agglomerator) | ||||||||||||

Model | Extruder | Screw diameter(mm) | L/D ratio | Power(kw) | Productivity(PE)(kg/h) | Productivity(PP)(kg/h) | ||||||

FSJ70 | 70/33 | φ70 | 33:1 | 110 | 110-150 | 100-130 | ||||||

FSJ85 | 85/33 | φ85 | 33:1 | 155 | 180-250 | 150-200 | ||||||

FSJ100 | 100/33 | φ100 | 33:1 | 210 | 280-350 | 250-300 | ||||||

FSJ130 | 130/33 | φ130 | 33:1 | 300 | 480-550 | 400-480 | ||||||

FSJ160 | 160/33 | φ160 | 33:1 | 370 | 650-750 | 550-650 | ||||||

FSJ180 | 180/33 | φ180 | 33:1 | 460 | 800-1000 | 750-850 | ||||||

Main Parameters

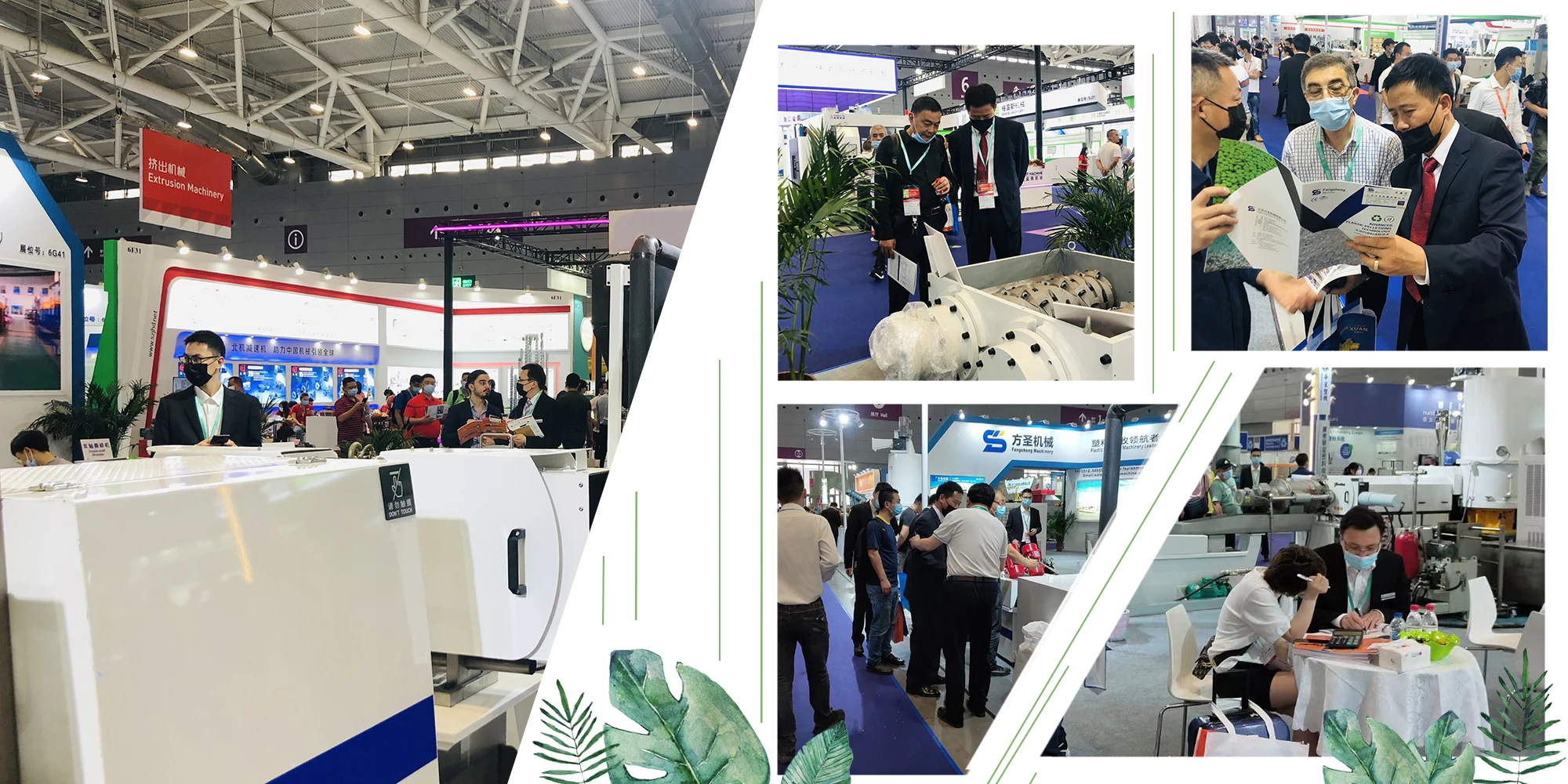

Successful Project

OUR COMPANY

FAQ

1.Your company is a transactional company or an industrial manufacture factory?

We are an industrial manufacture factory which locates in Zhangjiagang city.

2.All of your products are made by your self or compacted via purchasing the others?

We have independent technical team who focus on making machines, all the products are made by our technical team.

3.What is the ability of your factory?

About 80 lines per year.

4.Do you have any other services about your products?

We have a lot of experience on making projects and specifications for our clients, also we have a fixed service system.

5.How do you make the quotation for clients?

The price depends on quality and performance but the clients should be satisfied first.

We are an industrial manufacture factory which locates in Zhangjiagang city.

2.All of your products are made by your self or compacted via purchasing the others?

We have independent technical team who focus on making machines, all the products are made by our technical team.

3.What is the ability of your factory?

About 80 lines per year.

4.Do you have any other services about your products?

We have a lot of experience on making projects and specifications for our clients, also we have a fixed service system.

5.How do you make the quotation for clients?

The price depends on quality and performance but the clients should be satisfied first.

VIEW MORE

You may like

-

Plastic granulation recycling line PE PP film granulator plastic film granulator granulator

-

Cheap price PP PE granulation plastic granulator granulator

-

Hot Selling Plastic Granule Manufacturing Process

-

HDPE PP ABS PE Recycled Plastic Pelletizer Plastic Pelletizer

-

Plastic granulator Pe water ring eager cutting granulator plastic granulator

-

TL100 waste plastic film granulation concentrator granulation recycling

-

Pp Pe plastic woven bag granulation production line granulation system

-

Factory direct sales waste granulation line plastic recycling machine granulator

-

ps recycled waste granulator extrusion LDPE granulator production line

-

SDHT plastic granulator recycling machine extruder granulator factory direct sales hot sale

Other Products

-

$50000.00 / set

$50000.00 / set -

$80000.00 / set

$80000.00 / set

Related Search

granulator pp pe film pelletizing

waste bags recycling pelletizer

pp/pe/hdpe pellet extruder /pelletizing line

mini waste plastic pyrolysis plant

waste plastic recycling machine

pyrolysis waste plastic recycling machinery

waste plastic recycling pyrolysis machinery

plastic granulator plant

waste plastic recycling to oil machinery

recycling fuel oil from waste plastic