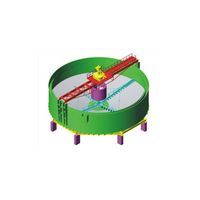

high rate sludge tailing gold ore mining thickener for sale

-

Supplier: Zhengzhou Hengxing Heavy Equipment Co., Ltd. -

Region: Henan, China -

Contact: Ms Sara Pang -

Price: $4000.00 /set -

Min. Order: 1 set

| Supply Ability: | 20 Set/Sets per Month; | After-sales Service Provided: | Online support,Video technical support,Field installation, commissioning and training,Field maintenance and repair service,Engineers available to service machinery overseas; |

| Dimension(L*W*H): | as requested; | Certification: | ISO9001:2008&CE; |

| Applicable Industries: | Energy & Mining; | Capacity Arrange: | 5.6---3030 t/d; |

| Payment Terms: | L/C,T/T; | Product Name: | mining thickener; |

| Color: | optional; | Application: | gold ore thickener; |

| Motor Type: | AC Motor; | Place of Origin: | Henan China; |

| Type: | Mining Thickener; | Packaging Detail: | standard package in wooden case or in nude or other as requested; |

| Port: | Qingdao, China port; | Production Capacity: | 1-3400t/d; |

| Condition: | New; | Brand Name: | Hengxing; |

| Warranty: | 1 Year; | Pool Sediment area: | 176㎡; |

| Total Weight: | 22t; |

gold ore mining thickener

Introduction:

Thickener machine is used for concentrate and tailings dewatering, improving the concentration of 20~30% of the pulp to about 40~70%. Thickener is actually not simply settling equipment, but the a new dewatering equipment which combinate the mud layer filtering function.

Application:

The thickener widely used in metallurge, mining, coal, chemicals, building materials, environmental protection and other departments to concentrate sludge, waste water and waste slag, improving utilization and underflow transport concentration and protecting the environment.

Working principle:

Before slurry entering the high efficient thickener machine, the getter device romove most of the gas contained in the slurry. Then the slurry feed into the mixing device through the feed tube, and the slurry thoroughly mixed with an appropriate amout of flocculant in the mixing apparatus to form a good flocculation state. Then, the slurry flocculation spread aroud to form a sludge layer in the bottom of the pool. At the same time, the sludge layer plays a role in filtering, preventing fine particles of sludge rise. Not fully flocculated slurry will continue mixting with flocculation and continue growing until reach the slurry layer. Finally, the concentrated material discharged from the central port and the whey discharged form the overflow port under the

Structure:

High efficient thickener is generally mainly consists of the thickener pool,cake rack ,gear, cake rack lifting machine, feeding device, discharging device and signal safety devices and other components.

Working feature:

1) add flocculant to increase diameter of the solid particles, thus speeding up the settling velocity;

2) Installate the tilt plate shorten the the particles settling distance, increased sedimentation area;

3) Equipped with a complete self control facilities;

4) Play mud deposition flocculation dense phase layer the role of filtering, compressing and enhancing capacity.

Main technical parameter:

Model | Pool(m) | Cake rack | Motor (kw) | Capacity

| Weight (t) | ||

Dia | Depth | Area | Min/r | ||||

NZS-1 | 1.8 | 1.8 | 2.54 | 2 | 1.1 | 5.6 | 1.235 |

NZS-3 | 3.6 | 1.8 | 10.2 | 2.5 | 1.1 | 22.4 | 3.064 |

NZS-6 | 6 | 3 | 28.3 | 3.7 | 1.1 | 62 | 8.751 |

NZSF-6 | 6 | 3 | 28.3 | 3.7 | 1.1 | 62 | 3.649 |

NZ-9 | 9 | 3 | 63.6 | 4.34 | 3 | 140 | 6.134 |

NZS-9 | 9 | 3 | 63.6 | 4.34 | 3 | 140 | 5.146 |

NZS-12 | 12 | 3.5 | 11.3 | 5.28 | 3 | 250 | 8.15 |

NZ-15 | 15 | 4.4 | 176 | 10.4 | 5.2 | 350 | 21.757 |

NZ-20 | 20 | 4.4 | 314 | 10.4 | 5.2 | 960 | 24.504 |

NZ-30 | 30 | 7.2 | 707 | 13.7 | 4.4 | ----- | 31.8 |

NZS-45 | 45 | 4.6 | 1590 | 20 | 5.2 | 515 | 47.81 |

NT-15 | 15 | 3.5 | 177 | 8.4 | 5.5 | 390 | 11 |

NQ-18 | 18 | 3.5 | 255 | 10 | 5.5 | 560 | 10 |

NQ-24 | 24 | 3.4 | 452 | 12.7 | 7.5 | 1000 | 23.3 |

NG-30 | 30 | 3.6 | 707 | 16 | 7.5 | 1570 | 26.42 |

NJ-38 | 38 | 4.9 | 1134 | 10-25 | 11 | 1600 | 55.26 |

NT-45 | 45 | 5 | 1590 | 19.3 | 11 | 2400 | 28.64 |

NTJ-53 | 53 | 5 | 2202 | 23.2 | 15 | 6250 | 79.80 |

NT-100 | 100 | 5.7 | 7846 | 43 | 15 | 3030 | 199.65 |

-

Low cost mud water sludge thickener liquid thickener

-

Hua Center Transmission Concentrate Tailings Thickener Dehydration

-

Ex-factory price copper-iron-lithium ore sedimentation tank sludge thickener

-

Fully automatic mine tailings concentrate treatment mud sewage sludge dehydration high-efficiency thickener price

-

Sludge Collector Circular Settling Thickener Tank Sludge Scraper Peripheral Drive Sludge Classifier Thickener Price For Sale

-

Gold ore cyanide leaching plant gold ore concentrator

-

Factory price sedimentation tank NZS-3 slime thickener for sale

-

Tailings gold beneficiation high-efficiency thickener

-

mine iron ore dewatering thickener/slurry sludge thickener tank sedimentation tank

-

Low Price Sludge Thickening Tank Supplier

Other Products

-

$6000.00 / set

$6000.00 / set -

$6000.00 / unit

$6000.00 / unit -

$5000.00 / set

$5000.00 / set