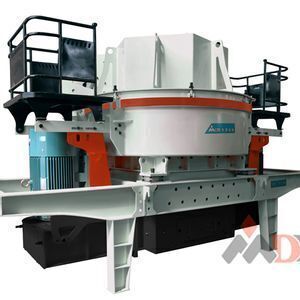

DVSI sand cement brick making machine equipment from China

-

Supplier: Shanghai Dongmeng Road & Bridge Machinery Co., Ltd. -

Region: Shanghai, China -

Contact: Ms Shanghai DM -

Price: $4600.00 /set -

Min. Order: 1 set

| Core Components: | PLC,Engine,Bearing,Gearbox,Motor,Pressure vessel,Gear,Pump; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Installation: | Engineer to guide; | Selling Units: | Single item; |

| Place of Origin: | Shanghai China; | Condition: | New; |

| Max. Feed Size: | 40mm; | Voltage: | 220/280/350/380v; |

| Video outgoing-inspection: | Provided; | Local Service Location: | Viet Nam,Philippines,Indonesia,Russia,Malaysia,Sri Lanka,Kazakhstan,Uzbekistan; |

| Model: | DVSI85; | Brand Name: | Shanghai DongMeng; |

| Power: | 110-360kw; | Rotor Speed: | 1630R/Min; |

| Applicable Industries: | Machinery Repair Shops,Construction works ,Energy & Mining; | Motor brand: | Siemens; |

| Weight: | 14.1t,10-25; | Rotor Diameter: | 850mm; |

| Capacity: | 250-350t/h; | Warranty: | one year; |

| Key Selling Points: | Long Service Life; | Warranty of core components: | 1 Year; |

| Package Preview: | ; | Showroom Location: | Viet Nam,Philippines,Indonesia,Russia,Sri Lanka,Kazakhstan,Uzbekistan,Malaysia; |

| Dimension(L*W*H): | Specific One; | Marketing Type: | Hot Product 2019; |

| Machinery Test Report: | Provided; | Certification: | CE,ISO9001:2008 ,SGS; |

| Single package size: | 5.2X2.62X3.04 cm; | Dimension: | 5200*2620*3040mm; |

| Packaging Detail: | Export standard container 20GP OR 40GP,40HQthe spare parts in wooden case.mobile crushing plant In bulk and roll-roll shipment for sand brick making machine; | Motor: | 2*160kw; |

| Single gross weight: | 14.1 KG; |

DVSI sand cement brick making machine equipment from China

Dongmeng VSI Sand Making Machine Application

DVSI Sand maker is our patented machine, developed solely by Dongmeng. Compared with conventional PCL type sand maker, it is with higher capacity and much light in volumn.

It can work with single or double electric motor. DVSI sand making machine applied for powder process of material products including metal and nonmetal ore, fireproof material, bauxite, diamond dust, architectura materials,

artificial sand and all kinds of metal and ore materials.

Working Principle of Sand Making Machine

The materials fall into the impeller from the head of the machine and with the function of high-speed centrifugal force, they strongly hit against and highly grind the other parts of the materials bypass flowing around the impeller in an umbrella form.

After mutual impaction and between the impeller and the machine shell, the materials will move like a vortex and will be impacted, rubbed and pulverized many times. Then they will come to the required fineness controlled by screening equipment, and discharge from the bottom of the VSI Sand maker.

Structural Drawing of Sand making Machine

Advantages and Characteristics of sand brick making machine 1. High-efficiency, higher output but lower energy consumption, 30% power saving and 20% output increasing compared with similar products.

2. Perfect protection system, all quick-wear areas are equipped with guard plates.

3. NN type automatic air circulation system, less emissions pollution through interior air circulation system, zero energy consumption.

4. Immune to moisture content ,the moisture content is raw moisture can reach 8%.

5. the upper roof can be lifted by hydraulic system.

6. lubrication oil station is adopted to lubricate the major bearing in circulation to ensure constant supply.

DVSI Sand Making Machine used in cement and brick macking cases

Sand Making Machine in Exhibition

Sand Making Machine in Our Factory

Sand Making Machine in Working Sites

Shanghai DongMeng Road&Bridge Machinery Co., Ltd. Is a leading professional manufacturer of crushing &screening machinery in China. Shanghai Dongmeng set machinery design, development, production, sales, after-sales service as one. We have more than 200 workers, 30 senior technical staff, with factory area of more than 20,000 square meters.

1. How to install crushing mining equipment and machineries?

If the buyer ask the seller to sent engineers to guard to install the machines at their sites, the buyer should take all the charges for the engineers and pay the salary ($50 each person per day).day).

3. Payment?

If you want us recommend a suitable type for you, please provide the information as below:

1) Do you need a single crusher or a crushing production line?(include the feeder,crusher,screen,conveyor and so on)

2) What is the capacity you need? (eg.100t/h, 200t/h, 350t/h, 500t/h...)

3) What is the max size of the stone? (eg.200mm, 400mm, 500mm, 700mm...)

4) What is the output size you need? (eg. 0-5mm, 5-10mm, 10-20mm, 20-40mm...)

5) What is the stone type? (eg. granite, basalt, cobble, marble...)

5.What could you help me to do for the business ?

Many thanks for your trust, we can provide you with proposal chart for complete production lines,

spot inspection and operator traning according to your demands and the conditions of your site, we can help you choose the suitable equipments, rilling rig, loader, trucks, excavators and so on.

-

Large capacity trailer mobile impact crushing station limestone granite stone crushing stone crushing station price

-

gold mine electric rock crusher rock price

-

Vertical Shaft Impact Crusher Mechanism Sand Machine Manufacturer

-

Simple sand making sand line crusher hammer crusher mobile

-

China Hot Selling Quarry Crusher Manufacturer, Aggregate Stone Crusher Vertical Shaft Crusher VSI Sand Making

-

Stone sand making VSI artificial sand making machine price

-

artificial sand making machine, sand making machine, sand making equipment

-

PLFC 1250 VERTICAL SHAFT DRYER

-

Large Capacity Efficiency Fine Impact Crusher Rock Crusher Line Cone Crusher Price

-

Zenith Silica Sand Receiving

Other Products

-

$6600.00 / set

$6600.00 / set