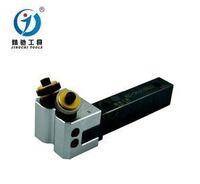

High strength internal punching rotary broach/broaching tool machining parts

-

Supplier: Taizhou Ke Chi Machinery Co., Ltd. -

Region: Zhejiang, China -

Price: $302.00 /piece -

Min. Order: 1 piece

| Model Number: | KC-CX08P; | Type: | Rotaty broach tool holder; |

| Hardness: | Suit less than HRC30; | OEM: | Accept; |

| Place of Origin: | Zhejiang China; | MOQ: | 1; |

| Application: | Machining; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| Shank Size: | Mohs taper shank/Straight shank; | Packing: | Customers' Request; |

| Supply Ability: | 500 Piece/Pieces per Month vertical broaching machine splined hole wobble broach rotary bro; | Product Name: | rotary broach tool; |

| Packaging Detail: | Carton; | Port: | Ningbo or Shanghai; |

| Certificate: | ISO9001; | Brand Name: | Jingchi tools; |

| Material: | High speed steel; |

High strength internal punching rotary broach/broaching tool machining parts

KC-CXP SERIES ROTARY BROACH TOOL

Rotary broach tool works by rotating the cutting force.It is most suitable for geneal machines,CNC automatic lathe,drilling machine.It can be used to make blind holes,through holes or regular/irregular polygons.Apart from standard hexagon and square holes,special shapes such as star shape and spline can also be cstomized.

1.Product performace and features

1.No need to malke Punch head or electrode,reduce the cost,quaity is good, improve efficiency,has strong generality.

2.One step of lathe work,reduce process and processing time.Use this tool can make square hole and hexagonal hole etc.Only need 30s to process a hexagonal hole which is 10mm width and 15mm depth.

3.Suitable to process parts which hardness less than HRC30.

2.Method of use

1.Use rotary broach tool,you can rotate the tool or the parts.It means you can use on lathe,milling machine,drill machine and CNC machine.In order to make sure the working accuracy,you must calibrat center.

2.Working speed:800-2000R.P.M,Feed:0.02-0.1mm/rev,Increase 2-3times for copper/aluminum parts

KC-CXP INTERNAL ROTARY BROACH TOOL

Maximum processing capacity:

CX08P: ![]() ≤10

≤10 ![]() ≤7

≤7

CX16P: ![]() ≤17

≤17 ![]() ≤12

≤12

Product Data

Model | Size | Broach Head | ||||

Shank | D1 | d | L | C | ||

KC-CX08P2 | MT2 | 42 | 8 | 80 | 18 | KC-CT08-*** |

KC-CX08P3 | MT3 | |||||

KC-CX08P4 | MT4 | |||||

KC-CX08P12 | Φ12×40 | |||||

KC-CX08P16 | Φ16×40 | |||||

KC-CX08P20 | Φ20×60 | |||||

KC-CX08P25 | Φ25×60 | |||||

|

| |||||

KC-CX16P2 | MT2 | 58 | 16 | 125 | 40 | KC-CT16-*** |

KC-CX16P3 | MT3 | |||||

KC-CX16P4 | MT4 | |||||

KC-CX16P16 | Φ16×40 | |||||

KC-CX16P20 | Φ20×60 | |||||

KC-CX16P25 | Φ25×60 | |||||

KC-CX16P32 | Φ32×80 | |||||

TaiZhou KeChi machinery Co.,Ltd is a company specialising in the production of mirror roller burnishing tools, rotary broach tools, knurling tools, combined skive-burnishing tool, diamond burnishing tool.And setting research and development production,sales in one integrated manufacturers.The company has its own R & D team and after-sales service team,.It focus on the mirror roller burnishing, rotary broach, knurling and other technical areas. During the past ten years, it has provided perfect solutions for thousands of customers in auto parts, aerospace, hydraulic, military, cylinder, ship, construction machinery, medical, agricultural machinery, air conditioning,motor and so on.

Our certificate

Workshop

Test equipment

Exhibition

1. Feedback within 2 hours

2. Professional suggestion on product;

3. Could issue the C/O(certificate of origin)to customer to reduce the tax;

4. Could accept payment terms of T/T, L/C, western union, paypal and etc.

1.You are traders or manufacturers?

A: We are a factory. you are most welcomed to visit us

2.Q:What is the material of your products?

A: The material is mainly steel,Cast iron(Ductile cast iron) We can also choose material as customer requirements.

3.What is the artwork of your products,can print our logo?

A: Yes,we can provide your logo.

4.Q: What is your MOQ ?

A: 1 set per style.

5.Q: What is the lead time?

A: It depends on your order quantity.

6.Q: What are your payment terms?

A: 30% deposit and balance T/T before shippment or L/C at sight.

-

2023 latest design best selling wholesale 14mm high hardness durable keyway broach gray AB grade keyway broach

-

Custom Factory Belt Opening Tool Blocks

-

Square hole broach carbide tungsten steel combination square push pull knife square slot knife broach military industry

-

Keyway Broaches Metric/Inch Sizes Push Style 3/4/5/6/8/10/12/14/16/18mm HSS Tools

-

Factory direct sale rectangular triangular spline broach hexagonal broach OEM tool box wooden time packing material origin high speed steel day

-

RJTOOLS Best Selling High Quality Carbide Broach Size Supplier For Sale

-

CHTOOLS HSS Core Drill High Quality Broach with Universal Shank

-

Factory direct sales rectangular triangular spline broach hexagonal broach

-

Broach cutter carbide push-pull rifling broaching machine

-

HSS No.70 Metric/Imperial Keyway Broaching Tool Set with Bushing and Spacer

Other Products

-

$300.00 / piece

$300.00 / piece -

$217.60 - $221.70 / piece

$217.60 - $221.70 / piece -

$140.00 / piece

$140.00 / piece -

$305.00 / piece

$305.00 / piece -

$375.00 / piece

$375.00 / piece -

$379.80 / set

$379.80 / set -

$210.00 / piece

$210.00 / piece -

$365.60 / set

$365.60 / set -

$192.80 / piece

$192.80 / piece -

$450.00 / piece

$450.00 / piece